5083 h111 Aluminum Plate Sheet

Standards: ASTM B209/EN 485-2 and so on Strictly Control Product Quality

What is 5083 H111 Aluminum Plate?

5083 aluminum plate is one of the common alloys of 5 series alloys. There are many states of 5083 aluminum plate, and H111 state is a common one.

5083 h1111 aluminum plate is an aluminum-magnesium alloy. Its production process is relatively complex and the requirements for equipment are relatively high. Therefore, the price is higher than ordinary aluminum plates.

5083 H111 is a special tempering state of 5083 aluminum alloy. The "H" in the tempering code stands for strain hardening, and "111" means it has been strain-hardened and stabilized to improve its mechanical properties.

Advantages of Al 5083 h111 material:

- Has excellent corrosion resistance

- High strength

- Good solderability

The h111 of 5083 h111 aluminum actually refers to the tempered state. In order to achieve this tempering, the final annealed 5083 aluminum plate is appropriately work hardened, but the degree of work hardening is not as high as the h11 alloy plate. Therefore, 5083 h111 aluminum shows sufficient strength, good processability, and high corrosion resistance, especially in harsh environments.

5083 h111 aluminum plate has stable performance, low density and high strength. It is used in aluminum alloy silos, chassis cabinets and ships. It is a special aluminum plate for marine aluminum plates, lightweight automobile aluminum plates and tank truck aluminum plates.

H111 Tempering is achieved by heating the material to a specified temperature and then allowing it to cool rapidly in air or water. It is commonly used in marine and other high-stress applications.

5083 H111 provides a balance of strength and formability. It is usually chosen when high strength and good formability are required. Other status designations, such as H116 and H321, can be selected for specific applications based on their unique capabilities.

5083 H111 Aluminum Plate Typical Applications:

- Marine applications: hulls, superstructures, decks, masts, booms, gangways, etc.

- Transportation: automotive, truck, trailer, and rail components

- Pressure vessels: cryogenic tanks, storage tanks, and piping

- Industrial components: high-pressure pipelines, mining equipment, and industrial machinery

5083 h111 Aluminum Plate Features

5083 H111 aluminum alloy is one of the strongest alloys that is not heat-treatable. This makes it suitable for applications requiring high-strength materials.

1. Resist corrosion from seawater and industrial chemicals

5083 H111 aluminum alloy has excellent corrosion resistance, especially to seawater and industrial chemicals. This makes it ideal for marine and chemical applications as it resists corrosion and oxidation.

2. Maintain strength after welding

5083 H111 aluminum alloy retains excellent strength after welding. This is important for applications that require welding for fabrication or repair, as welding often has an impact on the material's properties.

3. Low-temperature application

5083 H111 aluminum alloy is also suitable for cryogenic applications as it is capable of cooling to -195°C. At very low temperatures, the alloy's mechanical properties, including tensile strength and yield strength, are improved by 40% while maintaining excellent toughness.

It should be noted that for 5083 H111 aluminum alloy, use is not recommended in environments where the temperature limit exceeds 65°C. These performance characteristics make it widely used in many industries and applications.

5083 H111 Aluminum Plate Sizes

5083 Specific product standards, finishes, and equivalent materials may vary by supplier and specific application requirements. It is best to consult a supplier to determine the best product for your project.

5083 H111 Aluminum Plate Sheet Specifications

| Typical alloy | 5083 Aluminum Sheet |

| Material temper | h111 |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 100-2800 |

| Length (mm) | Customize |

| Typical product | boat buling, vehicle bodies, welding parts, tread plate, etc. |

En Aw 5083 h111 Equivalent

- AA 5083 H111

- UNS A95083

- ISO AlMg4.5Mn0.7

| Country/Region | Standard | Equivalent |

|---|---|---|

| USA | ASTM B209 | 5083-H111 |

| Europe | EN 573-3 | AW-5083 |

| Germany | DIN 3.3547 | AlMg4.5Mn0.7 |

| France | NF A50-411 | |

| Italy | UNI 9000 | |

| UK | BS 1470 | 5083-H111 |

5083 h111 Aluminum Plate Thickness Tolerance

The thickness tolerance for 5083 H111 aluminum plates can vary depending on the manufacturing standards, specific supplier, and the precision required for your application. Typically, the thickness tolerance for aluminum plates, including 5083 H111, is specified in industry standards such as ASTM B209 (Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate) or by the manufacturer's specifications.

In general, common thickness tolerances for aluminum plates, including 5083 H111, are often expressed as a percentage of the nominal thickness.

Typical thickness tolerances may range from ±5% to ±10% of the nominal thickness.

For example, if you have a 5083 H111 aluminum plate with a nominal thickness of 10 millimeters, the thickness tolerance could be within ±0.5 to ±1 millimeter.

However, it's crucial to refer to the specific standards or specifications provided by the manufacturer or supplier to determine the exact thickness tolerance for the 5083 H111 aluminum plates you intend to use. These tolerances can also vary based on the thickness range and the intended application of the plates.

Mechanical Performance Advantages of 5083 h111 Aluminum Plate

5083 h111 aluminum plate is a representative aluminum alloy product with medium strength, corrosion resistance and welding performance, and is easy to process and shape.

The mechanical properties of 5083 h111 aluminum plate make the processed products suitable for manufacturing medium-load welded pipes, liquid containers and other parts that require high plasticity and corrosion resistance.

Haomei Aluminum 5083 h111 aluminum plate is mainly used in shipbuilding, tank car bodies and high-voltage switches. 5083 aluminum plate can also be used as a rust-proof aluminum plate. Its rust-proof aluminum strength is about 20% higher than that of 5052 aluminum plate. Rust-proof aluminum aluminum plate cannot be strengthened by heat treatment, has low strength and high plasticity.

Aluminum 5083 H111 Data Sheet

Aluminum 5083 H111 Mechanical Properties

5083 H111 aluminum plate is an aluminum plate with a magnesium content exceeding 4.0%. Provides required mechanical properties and resistance to spalling corrosion. Its tensile strength (MPa) is greater than 305Mpa, conditional yield strength (Mpa) is greater than 215MPa, elongation 10 (%) is greater than 20, and elongation (5%) is greater than 12.

5083 H111 Aluminum Plate Physical Properties

| Property | Value |

|---|---|

| Density | 2.66 g/cm³ |

| Melting range | 570-640°C |

| Thermal conductivity | 121 W/(m·K) |

| Electrical conductivity | 24% IACS |

| Modulus of elasticity | 72 GPa |

| Poisson's ratio | 0.33 |

5083 H111 AluminuM Plate Chemical Composition

| Element | Percentage by Weight |

|---|---|

| Silicon | 0.4% |

| Iron | 0.4% |

| Copper | 0.1% |

| Manganese | 0.4-1.0% |

| Magnesium | 4.0-4.9% |

| Chromium | 0.05-0.25% |

| Zinc | 0.25% |

| Titanium | 0.15% |

| Others | 0.15% |

| Aluminum | Remaining |

5083 H111 Aluminum Plate vs. 5083 H116 Aluminum

5083 H111 and H116 are both tempered names for the same aluminum alloy. The main difference between the two is their mechanical properties, especially their strength and ductility.

5083 H111 is strain-hardened and partially annealed to be more ductile than H116. Less strong than H116, but easier to form and weld. It is commonly used in applications requiring high formability and good corrosion resistance, such as the marine and transportation industries.

Strength and Hardness: 5083 H116 is strain-hardened and stabilized for increased strength and hardness compared to H111. It has good resistance to stress corrosion cracking and fatigue resistance and is suitable for structures with harsh environments and high stress levels such as shipbuilding and offshore platforms.

Application: The choice between 5083 H111 and H116 will depend on specific application requirements.

- H111 is more suitable for applications that require good formability and weldability.

- H116 is more suitable for applications requiring high strength and resistance to stress corrosion cracking.

Weight of 5083 h111 Aluminum Plate

The weight of a 5083 H111 aluminum plate can vary depending on its dimensions (length, width, and thickness) and the density of the aluminum alloy. To calculate the weight of a specific 5083 H111 aluminum plate, you can use the following formula:

Weight (in kilograms) = Length (in meters) x Width (in meters) x Thickness (in meters) x Density (in kilograms per cubic meter)

The density of aluminum 5083 alloy is approximately 2.68 grams per cubic centimeter (g/cm³) or 2680 kilograms per cubic meter (kg/m³).

For example, if you have a 5083 H111 aluminum plate with the following dimensions:

- Length: 2 meters

- Width: 1 meter

- Thickness: 10 millimeters (0.01 meters)

You can calculate its weight as follows:

Weight = 2 meters x 1 meter x 0.01 meters x 2680 kg/m³ = 53.6 kilograms

So, the weight of this specific 5083 H111 aluminum plate would be approximately 53.6 kilograms.

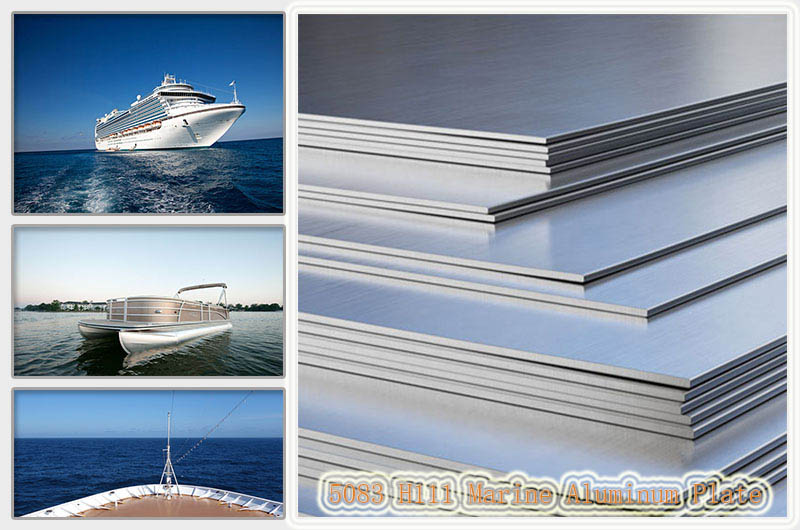

5083 H111 for Marine Aluminum Plate

5083 H111 aluminum alloy is commonly used in marine applications due to its excellent corrosion resistance and high strength to weight ratio. It is particularly suitable for the construction of ships and other marine structures exposed to harsh saltwater environments.

5083 H111 is easier to shape and shape without cracking, which makes 5083 H111 a popular choice for marine aluminum plates, which can be used in shipbuilding, offshore platforms, and other marine structures.

5083 H111 also has good weldability and machinability, making it easy to machine and suitable for a wide range of applications.

Al 5083 h111 is lightweight, helping to reduce the overall weight of marine structures and improve fuel efficiency.

5083 H111 is a reliable and durable marine aluminum plate material with excellent corrosion resistance, high strength, good formability, and weldability.

5083 h111 Aluminum Plate for Tank Truck Body

5083 h111 aluminum plate is optimally used in tank truck bodies, which can reduce the weight of each tank truck by 3-5 tons, thereby reducing the inertia of the vehicle body, improving transportation efficiency while also achieving energy saving and emission reduction effects.

5083 H111 Aluminum Plate Realizes Light Weight of Gas Storage Tank

5083 H111 Aluminum Plate is a reliable high-performance material for gas tank applications, offering a range of advantages including lightweight, high strength, weldability, and corrosion resistance.

The 5083 H111 aluminum sheet helps reduce the weight of the gas tank, which improves fuel efficiency and increases the vehicle's payload capacity. This is because aluminum is much lighter than steel, yet still offers high strength and durability.

The corrosion resistance of the 5083 H111 aluminum plate makes it ideal for use in gas storage tanks that are often exposed to harsh and corrosive environments. This helps ensure that the tank remains durable and reliable over time, even under challenging conditions.

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5083 Aluminum Plate for Tanker

Our products meet the quality standards and complete specifications, choosing the right Tanker Aluminum Plate will not deteriorate or cause pollution in harsh environments.

-

5083 Automotive Aluminum Plate Sheet

5083 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various auto parts by rolling, bending, stamping, and other processes.

5083 H111 Aluminum Sheet Plate Stock List

| Product | Size (In.) |

| 0.08" 5083 H111 Aluminum Sheet | 12" X 12" |

| 0.08" 5083 H111 Aluminum Sheet | 12" X 24" |

| 0.08" 5083 H111 Aluminum Sheet | 12" X 36" |

| 0.08" 5083 H111 Aluminum Sheet | 12" X 48" |

| 0.08" 5083 H111 Aluminum Sheet | 24" X 24" |

| 0.08" 5083 H111 Aluminum Sheet | 24" X 36" |

| 0.12" 5083 H111 Aluminum Sheet | 12" X 12" |

| 0.12" 5083 H111 Aluminum Sheet | 12" X 24" |

| 0.12" 5083 H111 Aluminum Sheet | 12" X 36" |

| 0.12" 5083 H111 Aluminum Sheet | 12" X 48" |

| 0.12" 5083 H111 Aluminum Sheet | 24" X 24" |

| 0.12" 5083 H111 Aluminum Sheet | 24" X 36" |

| 0.16" 5083 H111 Aluminum Sheet | 12" X 12" |

| 0.16" 5083 H111 Aluminum Sheet | 12" X 24" |

| 0.16" 5083 H111 Aluminum Sheet | 12" X 36" |

| 0.16" 5083 H111 Aluminum Sheet | 12" X 48" |

| 0.16" 5083 H111 Aluminum Sheet | 24" X 24" |

| 0.16" 5083 H111 Aluminum Sheet | 24" X 36" |

| 0.20" 5083 H111 Aluminum Sheet | 12" X 12" |

| 0.20" 5083 H111 Aluminum Sheet | 12" X 24" |

| 0.20" 5083 H111 Aluminum Sheet | 12" X 36" |

| 0.20" 5083 H111 Aluminum Sheet | 12" X 48" |

| 0.20" 5083 H111 Aluminum Sheet | 24" X 24" |

| 0.20" 5083 H111 Aluminum Sheet | 24" X 36" |

| 0.24" 5083 H111 Aluminum Sheet | 12" X 12" |

| 0.24" 5083 H111 Aluminum Sheet | 12" X 24" |

| 0.24" 5083 H111 Aluminum Sheet | 12" X 36" |

| 0.24" 5083 H111 Aluminum Sheet | 12" X 48" |

| 0.24" 5083 H111 Aluminum Sheet | 24" X 24" |

| 0.24" 5083 H111 Aluminum Sheet | 24" X 36" |

| 0.31" 5083 H111 Aluminum Plate | 12" X 12" |

| 0.31" 5083 H111 Aluminum Plate | 12" X 24" |

| 0.31" 5083 H111 Aluminum Plate | 12" X 36" |

| 0.31" 5083 H111 Aluminum Plate | 12" X 48" |

| 0.31" 5083 H111 Aluminum Plate | 24" X 24" |

| 0.31" 5083 H111 Aluminum Plate | 24" X 36" |

| 0.39" 5083 H111 Aluminum Plate | 12" X 12" |

| 0.39" 5083 H111 Aluminum Plate | 12" X 24" |

| 0.39" 5083 H111 Aluminum Plate | 12" X 36" |

| 0.39" 5083 H111 Aluminum Plate | 12" X 48" |

| 0.39" 5083 H111 Aluminum Plate | 24" X 24" |

| 0.39" 5083 H111 Aluminum Plate | 24" X 36" |

| 0.47" 5083 H111 Aluminum Plate | 12" X 12" |

| 0.47" 5083 H111 Aluminum Plate | 12" X 24" |

| 0.47" 5083 H111 Aluminum Plate | 12" X 36" |

| 0.47" 5083 H111 Aluminum Plate | 12" X 48" |

| 0.47" 5083 H111 Aluminum Plate | 24" X 24" |

| 0.47" 5083 H111 Aluminum Plate | 24" X 36" |

| 0.59" 5083 H111 Aluminum Plate | 12" X 12" |

| 0.59" 5083 H111 Aluminum Plate | 12" X 24" |

| 0.59" 5083 H111 Aluminum Plate | 12" X 36" |

| 0.59" 5083 H111 Aluminum Plate | 12" X 48" |

| 0.59" 5083 H111 Aluminum Plate | 24" X 24" |

| 0.59" 5083 H111 Aluminum Plate | 24" X 36" |

| 0.79" 5083 H111 Aluminum Plate | 12" X 12" |

| 0.79" 5083 H111 Aluminum Plate | 12" X 24" |

| 0.79" 5083 H111 Aluminum Plate | 12" X 36" |

| 0.79" 5083 H111 Aluminum Plate | 12" X 48" |

| 0.79" 5083 H111 Aluminum Plate | 24" X 24" |

| 0.79" 5083 H111 Aluminum Plate | 24" X 36" |

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 h112 Aluminum Plate Sheet

5083 h1112 aluminum has very good corrosion resistance and medium strength, and it is very suitable for welding. 5083 h112 aluminum plate can be used in transportation, pressure vessels, cryogenic equipment, towers and drilling platforms, gas/oil pipelines, ordnance and armor plates.

-

5083 h116 Aluminum Plate Sheet

5083 H116 aluminum plate is often used in the marine field because of its high low-temperature strength and corrosion resistance, which can extend the service life of the ship. Because of its light weight, it can better increase the ship's speed.

-

5083 H32 Aluminum Plate Sheet

5083 H32 aluminum plate has excellent corrosion resistance, good weldability, and high strength. The surface of the 5083 h32 Aluminum Plate has no oil spots, no waves, no scratches, no roll marks, and meets the production standards.

-

5083 o Aluminum Plate Sheet

5083-O aluminum is 5083 aluminum in the annealed state. It has the highest ductility compared to other variants of 5083 aluminum.

People also searched for Aluminum Plate

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5086 h32 Aluminum Plate Sheet

5086-H32 Aluminum is 5086 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5086 h111 Aluminum Plate Sheet

5086 h111 Aluminum Plate Sheet conforms to industry standards and specifications, the material has a consistent thickness, stable performance, smooth surface, and no defects such as cracks, voids, or impurities.

-

5086 h116 Aluminum Plate Sheet

5086 h116 aluminum plate sheet complies with industry standards and specifications, with a smooth surface and no defects at competitive prices.