5083 h116 Aluminum Plate Sheet

Complete Specifications Precise Size

What is 5083 H116 Aluminum Plate?

5083-H116 aluminum plate is a high magnesium alloy with good strength, corrosion resistance and machinability among non-heat treatable alloys. The surface is beautiful after anodizing. Arc welding performance is good. The main alloying element in 5083-H116 aluminum plate is magnesium, which has good corrosion resistance and weldability, as well as medium strength. Excellent corrosion resistance makes 5083 alloy widely used in maritime applications such as ships, as well as automobiles, aircraft welding parts, subway light rails, pressure vessels that require strict fire protection (such as liquid tank trucks, refrigerated trucks, refrigerated containers), refrigeration devices, TV towers, Drilling equipment, transportation equipment, missile parts, armor, etc.

5083 H116 is a special temper of the 5083 aluminum alloy. The "H116" designation indicates that the aluminum alloy has undergone a strain hardening and stabilization process, which makes the material more stable and offers greater strength and corrosion resistance than other tempered conditions.

The main features of the 5083-H116 aluminum plate

low density

High tensile strength

High elongation

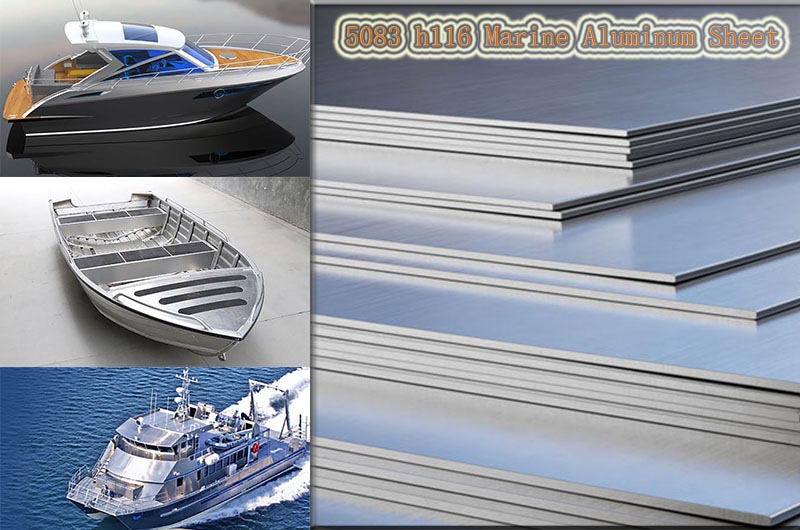

5083 H116 aluminum plate is a high-strength aluminum alloy plate mainly used in marine applications due to its excellent corrosion resistance, durability and weldability. "5083" refers to the alloy composition, which is mainly composed of aluminum, magnesium and manganese. The "H116" temper designation indicates that the aluminum plate has been strain-hardened and stabilized, resulting in increased strength and resistance to deformation. This state is particularly suitable for applications requiring high strength and corrosion resistance, such as shipbuilding, offshore structures and other marine components.

The weight of aluminum-magnesium alloy is lower than other alloy series under the same area. Aluminum alloy sheets in different heat treatment states are the main materials used in the automobile manufacturing industry (car doors, fuel tanks, seals), shipbuilding, and canning industries.

5083 aluminum alloy is a magnesium-containing high-strength material well suited for marine applications due to its corrosion resistance in saltwater environments. The "H116" temper is commonly used for aluminum plates and sheets in marine applications where strength, toughness, and corrosion resistance are key factors.

In general, the "H116" temper is characterized by higher tensile and yield strengths than the "H111" temper, another common temper for aluminum alloy 5083.

5083 h116 Aluminum Plate vs Other Temper

In addition to H116, 5083 aluminum plate also has many states, each state has its own unique mechanical properties and characteristics. The most common states of 5083 aluminum plates include:

- 5083 H111 Aluminum Plate

- 5083 H112 Aluminum Plate

- 5083 H321 Aluminum Plate

- 5083 H32 Aluminum Plate

- 5083 O Aluminum Plate

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.

-

5083 H32 Aluminum Plate Sheet

5083 H32 aluminum plate has excellent corrosion resistance, good weldability, and high strength. The surface of the 5083 h32 Aluminum Plate has no oil spots, no waves, no scratches, no roll marks, and meets the production standards.

-

5083 h111 Aluminum Plate Sheet

5083 aluminum is the strongest non-heat-treatable aluminum alloy. 5083 H111 aluminum is known for its superior performance in extreme environments, and 5083 O H111 sheet is used in marine and shipbuilding applications.

-

5083 h112 Aluminum Plate Sheet

5083 h1112 aluminum has very good corrosion resistance and medium strength, and it is very suitable for welding. 5083 h112 aluminum plate can be used in transportation, pressure vessels, cryogenic equipment, towers and drilling platforms, gas/oil pipelines, ordnance and armor plates.

-

5083 o Aluminum Plate Sheet

5083-O aluminum is 5083 aluminum in the annealed state. It has the highest ductility compared to other variants of 5083 aluminum.

To choose the appropriate 5083 aluminum plate, consider the following factors:

Application: Determine the specific application and requirements of your project. Are you building a boat, constructing a structural component, or working on a formable sheet metal project?

1. Strength Requirements

Consider the required strength and mechanical properties. H116 and H321 offer higher strength compared to H111 or O but may have different formability characteristics.

2. Corrosion Resistance

If your application involves exposure to corrosive environments like saltwater, prioritize tempers like H116 and H321, which provide enhanced corrosion resistance.

3. Formability

If you need to shape or form the aluminum plate extensively, choose a temper like H111 or O, which offer good formability.

4. Thickness

The plate thickness can influence the choice of temperature. Thicker plates often use H112 or H116 for structural integrity.

It is important to note that while these materials have similar properties and characteristics to aluminum 5083 h116, they may not be direct equivalents. It is always advisable to consult a supplier or materials expert to ensure that the particular material you are using is suitable for your application.

Aluminum 5083 h116 Data Plate

5083 h116 Aluminum Plate Mechanical Properties

| Property | Minimum Value |

| Tensile Strength (σb) | ≥305 MPa |

| Conditional Yield Strength (σ0.2) | ≥215 MPa |

| Elongation at Break (δ10) | ≥20% |

| Elongation at Break (δ5) | ≥12% |

5083 h116 Aluminum Plate Physical Properties (at room temperature)

- Density: 2.65 g/cm3

- Melting range: 570 - 640°C

5083 h116 Aluminum Plate Fabrication Properties

- Weldability: Good

- Machinability: Fair

- Formability: Good

- Heat Treatment: Annealing, stress-relieving

5083 h116 Aluminum Plate Chemical Composition

| Element | Minimum % | Maximum % |

|---|---|---|

| Magnesium (Mg) | 4.0 | 4.9 |

| Chromium (Cr) | 0.05 | 0.25 |

| Iron (Fe) | 0.0 | 0.4 |

| Manganese (Mn) | 0.4 | 1.0 |

| Silicon (Si) | - | 0.4 |

| Zinc (Zn) | - | 0.25 |

| Titanium (Ti) | - | 0.15 |

| Copper (Cu) | - | 0.1 |

| Others | - | 0.05 each, 0.15 total |

Typical 5083 h116 Aluminum Plate Applications

- Marine applications: Boat hulls, decks, and superstructures

- Aerospace and transportation industry: Aircraft wings, fuselage frames, and truck and trailer bodies

- Chemical processing industry: Tanks, piping, and other equipment that is exposed to corrosive environments

- Offshore structures: Construction of offshore oil rigs and other structures that are exposed to harsh marine environments

- Industrial machinery and equipment: Pressure vessels, storage tanks, and heat exchangers

Note: While the above information is typical for aluminum 5083 h116, actual properties may vary depending on the specific manufacturer and production process used.

-

5083 Marine Aluminum Plate Sheet

We have ABS, BV, DNV, CCS, and other marine classification certifications, and a strict quality control system to ensure that 5083 marine aluminum sheets meet the required standards and specifications.

-

5083 Aluminum Plate for Tanker

Our products meet the quality standards and complete specifications, choosing the right Tanker Aluminum Plate will not deteriorate or cause pollution in harsh environments.

-

5083 Automotive Aluminum Plate Sheet

5083 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various auto parts by rolling, bending, stamping, and other processes.

5083 h116 Marine Aluminum Plate

5083 h116 aluminum plate is commonly used on ships, yachts, cruise ships, and other hulls. It has good fatigue resistance, excellent welding performance, and good forming processing performance, so it is well-received by users.

- 1. Consider light weight. Marine aluminum plates generally use thin plates above 1.6mm and thick plates above 30mm. Aluminum-magnesium alloys have low density and are lightweight, which can reduce the weight of the hull and increase the load-carrying capacity.

- 2. Consider the corrosion resistance. The 5083 h116 aluminum plate belongs to the aluminum-magnesium alloy, which is a typical anti-rust aluminum and can adapt to the highly corrosive seawater environment for a long time.

- 3. Considering safety. 5083 h116 aluminum plate has medium strength, good processing performance, excellent weldability, fatigue resistance, no crack defects, and can still meet the strength and corrosion resistance requirements after processing, which can ensure the safety of ships.

Al 5083 h116 for Fishing Rod

The fishing rod is a kind of fishing tool, shaped like a slender and knobby rod, which is usually soaked in river water and needs to be corrosion-resistant. Therefore, the fishing rod is made of 5083 h116, and the 5083 aluminum alloy plate product has become the material for making fishing rods due to its excellent performance.

5083-H116 aluminum plate belongs to the series of hot-rolled aluminum plates. The 5083-H116 aluminum plate produced by Mingtai Aluminum adopts continuous casting and rolling processing technology, which has good forming processing performance, corrosion resistance, weldability, oxidation deep processing performance, and is widely used in various industries.

5083 h116 Aluminum Plate Price

The following table summarizes the relative price comparison of different 5083 aluminum plate states, with 1 indicating the most expensive and "5" indicating the cheapest in the 5083 series:

| Temper | Price Ranking |

|---|---|

| 5083 H116 Aluminum Plate | 1 |

| 5083 H321 Aluminum Plate | 2 |

| 5083 H111 Aluminum Plate | 3 |

| 5083 H112 Aluminum Plate | 3 |

| 5083 H32 Aluminum Plate | 4 |

| 5083 O Aluminum Plate | 5 |

The price of 5083 aluminum plates in different tempers can vary due to several factors. Here's a general comparison of their relative price ranges:

1. 5083 H111 Aluminum Plate

This temper typically falls in the mid-range in terms of price. It offers good formability, which can make it less expensive than some of the high-strength tempers.

2. 5083 H112 Aluminum Plate

H112 plates are often priced similarly to H111 plates. They are both work-hardened conditions with good formability, and the price difference is generally minimal.

3. 5083 H321 Aluminum Plate

H321 plates, designed for marine applications, may be slightly more expensive than H111 or H112 plates. The stabilizing treatment for improved corrosion resistance can add to the production cost.

4. 5083 H32 Aluminum Plate

H32 temper is usually competitively priced because it offers a balance between strength and formability. It is often used for general-purpose applications, making it readily available and affordable.

5. 5083 O Aluminum Plate

Annealed (O) plates tend to be more affordable compared to work-hardened or high-strength tempers. However, they are softer and have lower strength, which may not be suitable for all applications.

6. 5083 H116 Aluminum Plate

H116 plates are often among the more expensive options due to their high-strength properties and enhanced corrosion resistance. They are commonly used in critical marine and structural applications, which can drive up the cost.

These rankings are approximate and may vary based on factors such as market conditions, vendor pricing, and location. Quotes must be obtained from suppliers based on your specific requirements to obtain an accurate price comparison.

Popular 5083 h116 Aluminum Plate

H116 aluminum plate is not only a marine aluminum plate, but also commonly used in the field of transportation, for automobile fuel tanks, aircraft fuel tanks, etc. With the continuous development of my country's aerospace industry and transportation, automobiles, ships, and aircraft have become important means of transportation in modern times, and the demand for 5083-H116 aluminum sheets will also increase.

The magnesium alloy in the 5083-H116 aluminum plate has high strength, and the heat-treated alloy has good machinability, corrosion resistance, and welding performance. Generally, the price of an aluminum plate is divided into two parts, aluminum price plus processing fee. Due to its complicated processing technology, high technical and equipment requirements are required to achieve excellent performance, so the price of the 5083-H116 aluminum plate is generally slightly higher.

5083 H116 aluminum plate production process

- Melting and casting: The production of aluminum alloys usually starts with melting and casting. The various raw materials of the alloy are mixed in proportion and heated and melted, and then cast into billets or cast directly into shape.

- Uniform heat treatment: perform equalization heat treatment on the casting billet to make the internal structure reach a uniform state, which is beneficial to subsequent processing technology and stable performance.

- Edge planing: Trim the edges of the casting billet to remove irregular or defective parts to ensure the size and surface quality of the plate.

- Surface milling: Use milling machines and other equipment to smooth the surface of the plate and remove surface unevenness or oxide layer.

- Sawing: Cut the casting billet or processed plate into the required size according to the required size requirements.

- Heating: Preheat the plate before hot rolling to improve its plasticity, reduce processing deformation and improve processing efficiency.

- Hot rolling: The heated plate is plastically deformed through hot rolling equipment to adjust its thickness and shape while improving its mechanical properties.

- Intermediate annealing: Intermediate annealing is performed on the hot-rolled plate to eliminate processing stress and grain deformation, and improve the plasticity and toughness of the plate.

- Cold rolling: After intermediate annealing, the plate is cold rolled again to further adjust its thickness and surface quality.

- Stabilization annealing: Stabilization annealing is performed on the cold-rolled plate to make the internal structure reach a stable state and improve the mechanical properties and dimensional stability of the plate.

- Straightening: Straighten the plate after stabilization annealing to make the surface smooth and reduce the bending or warping of the plate.

- Sawing finished product: The straightened plate is finally cut according to the customer's requirements to make the finished plate.

- Performance testing: Conduct various performance tests on finished boards, including mechanical properties, chemical composition, surface quality, etc., to ensure that the products meet relevant standards and customer requirements.

5083 h116 Aluminum Plate Stock

| Product | Thickness (mm) | Length x Width Dimensions (mm) |

| 3/16" 5083 H116 Aluminum Plate ASTM B209 | 4.7625 mm | 1219 mm x 2438 mm |

| 3/16" 5083 H116 Aluminum Plate ASTM B209 | 4.7625 mm | 1524 mm x 3048 mm |

| 3/16" 5083 H116 Aluminum Plate ASTM B209 | 4.7625 mm | 1829 mm x 3658 mm |

| 3/16" 5083 H116 Aluminum Plate ASTM B209 | 4.7625 mm | Custom Sizes Available |

| 1/4" 5083 H116 Aluminum Plate ASTM B209 | 6.35 mm | 1219 mm x 2438 mm |

| 1/4" 5083 H116 Aluminum Plate ASTM B209 | 6.35 mm | 1524 mm x 3048 mm |

| 1/4" 5083 H116 Aluminum Plate ASTM B209 | 6.35 mm | 1829 mm x 3658 mm |

| 1/4" 5083 H116 Aluminum Plate ASTM B209 | 6.35 mm | Custom Sizes Available |

| 3/8" 5083 H116 Aluminum Plate ASTM B209 | 9.525 mm | 1219 mm x 2438 mm |

| 3/8" 5083 H116 Aluminum Plate ASTM B209 | 9.525 mm | 1524 mm x 3048 mm |

| 3/8" 5083 H116 Aluminum Plate ASTM B209 | 9.525 mm | 1829 mm x 3658 mm |

| 3/8" 5083 H116 Aluminum Plate ASTM B209 | 9.525 mm | Custom Sizes Available |

| 1/2" 5083 H116 Aluminum Plate ASTM B209 | 12.7 mm | 1219 mm x 2438 mm |

| 1/2" 5083 H116 Aluminum Plate ASTM B209 | 12.7 mm | 1524 mm x 3048 mm |

| 1/2" 5083 H116 Aluminum Plate ASTM B209 | 12.7 mm | 1829 mm x 3658 mm |

| 1/2" 5083 H116 Aluminum Plate ASTM B209 | 12.7 mm | Custom Sizes Available |

| 5/8" 5083 H116 Aluminum Plate ASTM B209 | 15.875 mm | 1219 mm x 2438 mm |

| 5/8" 5083 H116 Aluminum Plate ASTM B209 | 15.875 mm | 1524 mm x 3048 mm |

| 5/8" 5083 H116 Aluminum Plate ASTM B209 | 15.875 mm | 1829 mm x 3658 mm |

| 5/8" 5083 H116 Aluminum Plate ASTM B209 | 15.875 mm | Custom Sizes Available |

| 3/4" 5083 H116 Aluminum Plate ASTM B209 | 19.05 mm | 1219 mm x 2438 mm |

| 3/4" 5083 H116 Aluminum Plate ASTM B209 | 19.05 mm | 1524 mm x 3048 mm |

| 3/4" 5083 H116 Aluminum Plate ASTM B209 | 19.05 mm | 1829 mm x 3658 mm |

| 3/4" 5083 H116 Aluminum Plate ASTM B209 | 19.05 mm | Custom Sizes Available |

People also searched for Aluminum Plate

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5086 h32 Aluminum Plate Sheet

5086-H32 Aluminum is 5086 aluminum in the H32 condition. To achieve this state, the metal is strain-hardened and then stabilized to about one-fourth the strength between annealed (O) and fully hard (H38).

-

5086 h111 Aluminum Plate Sheet

5086 h111 Aluminum Plate Sheet conforms to industry standards and specifications, the material has a consistent thickness, stable performance, smooth surface, and no defects such as cracks, voids, or impurities.

-

5086 h116 Aluminum Plate Sheet

5086 h116 aluminum plate sheet complies with industry standards and specifications, with a smooth surface and no defects at competitive prices.