5182 Aluminum Plate Sheet

Temper: H19/H111/O Standard: ASTM B209, AMS-QQ-A-250/11

5182 aluminum is an alloy that belongs to the 5xxx series of aluminum alloys. Composed mostly of aluminum, magnesium, and a small amount of manganese, it has excellent corrosion resistance and strength.

5182 aluminum is a 5000 series aluminum alloy that is not heat treatable, but it has good corrosion resistance, high quality surface finish, excellent weldability using a variety of welding techniques, moderate strength, and ease of forming. These qualities make it excellent in the automotive and construction industries.

Common industries for 5182 aluminum sheets are the automotive, construction and packaging industries. In addition, it is also commonly used in packaging products such as beverage cans, containers, brackets and parts, as well as automotive parts such as hoods, doors and wings.

Q: What is the similarity between the 5182 aluminum plate and 5A02?

A: The performance of 5182 the aluminum plate is similar to that of 5A02, but because of the slightly higher magnesium content and a small amount of silicon added, the weldability is better than 5A02.

Q: Which welding methods are suitable for 5182 aluminum plates?

A: 5182 aluminum plate is suitable for welding by gas welding, argon arc welding, spot welding, and seam welding, and its welding performance is very good.

Q: What Material is aa5182?

A: AA5182, also known as aluminum alloy 5182, is a widely used aluminum alloy in various industries. It is part of the aluminum-magnesium alloy series, often referred to as the Al-Mg series.

5182 Aluminum Plate Properties

- Corrosion Resistance: 5182 Aluminum has excellent corrosion resistance, especially in marine environments. It is highly resistant to saltwater corrosion, making it suitable for applications such as marine components, fuel tanks, and automotive components.

- Formability: 5182 aluminum has good formability and can be used in various manufacturing processes such as bending stamping, and deep drawing.

- Weldability: It has good weldability and can be easily welded using common welding techniques, including MIG and TIG welding.

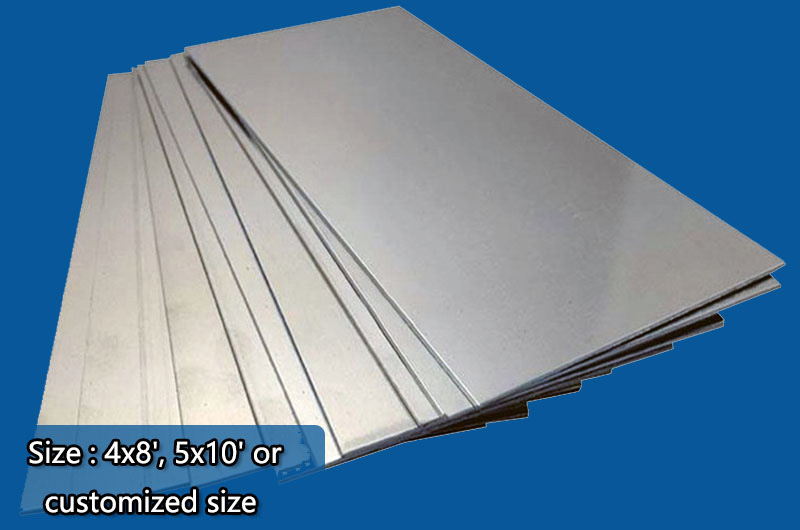

5182 Aluminum Plate Specifications

Al 5182 Plate Specifications

| Property | Vlaue |

|---|---|

| Size | 4x8', 5x10' or customized size |

| Thickness | 0.5 - 600mm |

| Width | 1000 mm - 2000 mm |

| Length | customized size |

Common Thickness of 5182 Aluminum Plate

- Sheet: 0.2mm - 6mm (0.008" - 0.24")

- Middle Plate: 6mm - 40mm (0.24" - 1.6")

- Thick Plate: 40mm - 200mm (1.6" - 7.9")

5182 Aluminum Plate Typical Temper

- O: annealed

- H32: Strain hardening and stabilization

- H34: Strain hardened and partially annealed

- H36: Strain hardened and thoroughly annealed

- H38: Strain hardened and fully annealed

NOTE: These specifications, dimensions, thicknesses, and tempers are generally for 5182 aluminum sheets, but specific availability may vary by manufacturer, supplier, and region.

5182 Aluminum Plate Tensile Strength

| Temper | Tensile Strength Range |

|---|---|

| 5182-O Aluminum Plate | 190 MPa (27, 500 psi) |

| 5182-H32 Aluminum Plate | 260 - 305 MPa (37, 700 - 44, 200 psi) |

| 5182-H34 Aluminum Plate | 290 - 335 MPa (42, 100 - 48, 600 psi) |

| 5182-H36 Aluminum Plate | 315 - 360 MPa (45, 700 - 52, 200 psi) |

| 5182-H38 Aluminum Plate | 345 - 380 MPa (50, 100 - 55, 100 psi) |

NOTE: These values are approximate and may vary based on specific manufacturing processes, dimensions, and testing standards. The tensile strength can also be affected by factors such as alloy purity and the specific heat treatment performed. It is always advisable to consult the aluminum supplier or manufacturer for accurate and up-to-date information on the tensile strength of 5182 aluminum in different tempers.

5182 Aluminum Plate Yield Strength

| Temper | Yield Strength Range |

|---|---|

| 5182-O Aluminum Plate | 80 MPa (11, 600 psi) |

| 5182-H32 Aluminum Plate | 160 - 200 MPa (23, 200 - 29, 000 psi) |

| 5182-H34 Aluminum Plate | 180 - 220 MPa (26, 100 - 32, 000 psi) |

| 5182-H36 Aluminum Plate | 200 - 240 MPa (29, 000 - 34, 800 psi) |

| 5182-H38 Aluminum Plate | 220 - 260 MPa (32, 000 - 37, 700 psi) |

NOTE: These values are approximate and yield strength may also be affected by factors such as alloy purity and the specific heat treatment performed.

5182 Aluminum Alloy Mechanical Properties

| Property | Value |

|---|---|

| Density | 2.7 gm/cc |

| U.T.S. | 280 to 420 MPa |

| Yield strength | 130 to 360 MPa |

| Fatigue strength | 100 to 130 MPa |

| Young's modulus | 68 GPa |

Aluminum Alloy 5182 Thermal Properties

| Property | Value |

|---|---|

| Melting Point | 640 °C |

| Specific heat capacity | 900 J/kg K |

| Thermal conductivity | 130 W/mK |

5182 Aluminum Plate Composition

| Element | Composition Range (%) |

|---|---|

| Aluminum | Balance |

| Magnesium | 4.0 - 5.0 |

| Manganese | 0.5 - 1.0 |

| Iron | 0.0 - 0.25 |

| Silicon | 0.20 - 0.50 |

| Copper | 0.1 max |

| Chromium | 0.05 - 0.25 |

| Zinc | 0.25 max |

| Titanium | 0.05 max |

| Other | 0.15 max (each), 0.05 max (total) |

5182 Aluminum Equivalent

- Alloy 5182

- AA5182

- UNS A95182

- AlMg4.5Mn0.4

- EN AW-5182

Typical 5182 Aluminum Plate

-

5182 h19 Aluminum Plate Sheet

5182 H19 is a non-heat treatable aluminum alloy with excellent corrosion resistance and ductility, good formability and strength. 5182 aluminum plate is suitable for gas welding, argon arc welding, spot welding, seam welding and other welding, and its welding performance is very good.

-

5182 h111 Aluminum Plate Sheet

5182 H111 is a non-heat treatable aluminum alloy with a good combination of formability and strength. 5182 H111 aluminum plate has high corrosion resistance and is very suitable for tank truck materials.

-

5182 o Aluminum Plate Sheet

5182 O aluminum plate is used for car doors, fenders, and engine hoods. It has good stamping effect, corrosion resistance, good formability, and high safety factor.

5182 H19 Aluminum Plate

H19 is the temper designation for aluminum and indicates the strain hardening state.

- 5182 H19 Aluminum Sheet is a strain hardening alloy with excellent formability and high strength.

- 5182 H19 Aluminum Sheet is typically used in applications requiring moderate strength and good formability, such as automotive panels, fuel tanks, and structural components.

5182 h111 Aluminum Plate

H111 is the temper designation for aluminum and indicates the stress relieved condition.

- 5182 H111 aluminum plate is a stress-relief alloy with good corrosion resistance and moderate strength.

- 5182 h111 Aluminum Sheet is typically used in marine applications where high corrosion resistance is required such as hulls, shipbuilding, and offshore structures.

5182 0 Aluminum Plate

0 is the tempering mark of aluminum, indicating a fully annealed state.

- 5182 0 aluminum sheet is in the fully annealed condition, making it soft and highly ductile.

- 5182 0 Aluminum Sheet is suitable for applications requiring excellent formability and ease of manufacture, such as packaging, signage, and architectural applications.

NOTE: Availability of specific sizes and dimensions may vary by supplier or manufacturer. It is recommended to consult the aluminum supplier or manufacturer for accurate information on the availability of 5182 aluminum plates in H19, H111, or 0 tempers.

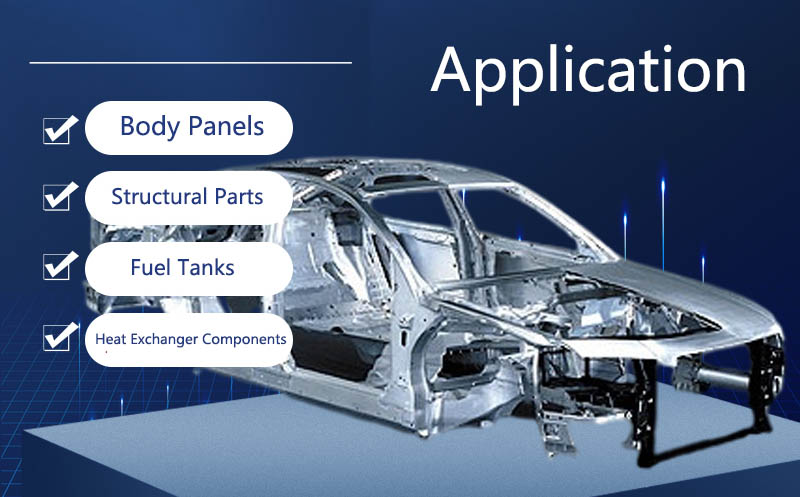

5182 Aluminum Plate Applications

Due to its excellent corrosion resistance and strength, 5182 aluminum is commonly used in the automotive industry for body panels, fuel tanks, and structural components. It is also used in the manufacture of trailers, truck bodies, and marine applications.

- Automotive industry: Body panels, inner and outer panels, etc.

- Packaging: Beverage can tabs, pull tabs, containers.

- Construction: Architectural elements, cladding.

- General sheet metal fabrication.

-

5182 Aluminum Plate for Tanker

Specifically designed for tankers, our 5182 aluminum plate offers excellent corrosion resistance and high strength for reliable leak and splash protection.

-

Aluminum Plate for Tanker Body

Tanker Body complies with various regulations, standards, and certifications related to safety, structural integrity, leak prevention, and cargo handling.

-

5182 Automotive Aluminum Plate Sheet

5182 Automotive Aluminum Plate Sheet has a flat shape, high quality, good corrosion resistance, good weight reduction, and energy-saving effects, and its safety and comfort are better provided.

-

Automotive Aluminum Plate for Car Door

The stamping effect of the Haomei Aluminum 5182 alloy aluminum plate is good, and the customer feedback is that the aluminum plate has no cracks after stamping.

5182 Automotive Aluminum Plate

5182 combines strength, formability, and corrosion resistance making it suitable for automotive applications. It provides lightweight construction, excellent corrosion resistance, and good formability required for body panels, structural components, fuel tanks, and heat exchangers.

Q: What is the application of 5182 aluminum plates in the automobile industry?

A: 5182 aluminum sheet is used in the automotive industry to make various parts of vehicles.

- Other Automotive Aluminum Alloy: 5083, 5754, 6111, 2024 or 6061

- Temper: various tempering according to the specific application

- Application: Body Panels, Structural Parts, Fuel Tanks and Heat Exchanger Components.

-

Example:

- Audi A8 (D2)’s structural panel

- BMW Z8's inner panel

- Rolls-Royce Phantom's structural panel

5182 H18 Aluminum Packaging

5182 is not normally used directly in beverage cans, but it can be used in cans bodies as part of an alloy combination. Its formability, corrosion resistance, and suitability for subsequent processing help produce high-quality beverage cans, caps, and closures.

- Other Packaging Aluminum Alloy: 3004, 3104 or 5052

- Temper: H19 or H48

- Application: beverage cans, caps, and closures

5182 Marine Aluminum Plate

While 5182 is not commonly used in direct marine applications, other alloys such as 5083, 5086, or 5456 are preferred for their high corrosion resistance and strength. However, 5182 may be suitable for some non-structural marine components due to its corrosion resistance.

- Other Marine Aluminum Alloy: 5083, 5086 or 5456

- Temper: H116 or H321

- Application: Hulls, superstructures, and components exposed to the marine environment.

5182 Construction Aluminum Alloy

5182 is not typically used directly in architectural applications such as siding and roofing. Other alloys such as 3003, 5005, or 6061 are often used for their formability, corrosion resistance, and strength suitable for construction purposes.

- Other Construction Aluminum Alloy: 3003, 5005 or 6061

- Temper: H14, H24 or T6

- Application: Siding, roofing, and architectural applications

Note: The specific aluminum alloys and tempers used in different applications may vary based on factors such as design requirements, performance specifications, and regional preference. The alloys mentioned are some common choices, but depending on the specific application and its requirements, there may be other suitable choices.

How is the 5182 Aluminum Plate Typically Processed and Fabricated?

5182 aluminum plates can be processed using common fabrication methods such as cutting, bending, forming, and welding. It is known for its excellent formability, making it easy to shape into various products.

5182 aluminum plate is known for its excellent formability and ease of processing, which makes it suitable for a wide range of fabrication methods. Here's how the 5182 aluminum plate is typically processed and fabricated:

1. Cutting

5182 aluminum plate can be cut into specific shapes and sizes using various cutting methods, including:

- Shearing: Straight cuts are made using a shear machine.

- Sawing: Circular or band saws are used to cut through thicker plates.

- Laser Cutting: High-precision laser cutting is suitable for complex shapes.

2. Bending and Forming: Due to its high formability, 5182 aluminum can be easily bent and formed into various shapes using press brakes or roll-forming machines. It can be used for making curved or angular components.

3. Welding: 5182 aluminum can be welded using common welding techniques, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or resistance welding. Proper cleaning, preparation, and the use of compatible filler materials are essential for successful welding.

4. Machining: When precision machining is required, 5182 aluminum can be machined using conventional machining tools like lathes, milling machines, and drills. It's important to use sharp cutting tools and appropriate cutting speeds and feeds.

5. Joining: 5182 aluminum can be joined using methods like riveting, adhesive bonding, and mechanical fastening, depending on the specific application requirements.

6. Surface Treatment: Depending on the application, 5182 aluminum may undergo various surface treatments, such as:

- Anodized: To enhance corrosion resistance and improve surface appearance.

- Painted or Coated: For added protection or to meet aesthetic requirements.

- Polished or Buffed: To achieve a desired surface finish.

7. Stamping and Deep Drawing: Due to its good formability, 5182 aluminum is suitable for stamping and deep drawing processes, making it ideal for the production of automotive body panels and components like cans and lids.

8. Heat Treatment: While 5182 aluminum is not typically heat-treated for strengthening purposes, it may undergo annealing or stress relieving to improve specific properties or reduce internal stresses.

It's important to note that the specific fabrication method chosen depends on the intended application, design requirements, and the capabilities of the equipment and machinery available. Proper handling, tool selection, and machining parameters are crucial to achieving the desired results when working with 5182 aluminum plates.

People also searched for Aluminum Plate

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5A06 Aluminum Plate Sheet

The magnesium content of 5A06 aluminum plate is higher than other 5 series alloys, with the highest magnesium content. It is a non-heat-treatable alloy with high strength and plasticity.

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5005 Aluminum Plate Sheet

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and is often used in applications requiring anodized surface treatments.

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.