5182 h19 Aluminum Plate Sheet

Stable Performance Competitive Price

5182-H19 Aluminum is 5182 aluminum in H19 condition. To achieve this state, the metal is strain-hardened to a strength of at least 10 MPa (or 1.5 ksi) above H18. It has the highest strength compared to other variants of 5182 aluminum.

What is H19 aluminum?

5182 h19 Aluminum Plate Sheet refers to the specific tempering mark of aluminum alloy.

- H19 Tempering: H19 is the strain hardening temper of aluminum, which means that the material has undergone a specific heat treatment process to increase strength.

- 5182 Alloy: 5182 is an aluminum alloy consisting primarily of aluminum, magnesium, and small amounts of other elements such as copper and chromium.

Aluminum sheet 5182 h19 is a super hard 5182 aluminum alloy. The hardness of 5182 is medium among 5000 alloys, but H19 means it is stronger than H18.

5182 h19 Aluminum Plate Features

- Excellent Formability

- High Strength

- Good Corrosion Resistance

Why Choose 5182 h19 Aluminum Plate?

Selecting 5182-H19 aluminum plate in H19 temper can be advantageous for certain applications for the following reasons:

1. 5182 h19 Aluminum Plate Provides Greater Strength

The H19 temper offers greater strength than some other tempers of 5182 aluminum.

5182-H19 aluminum plate is cold worked for high strength. This makes them suitable for applications where structural integrity and load-bearing capacity are critical.

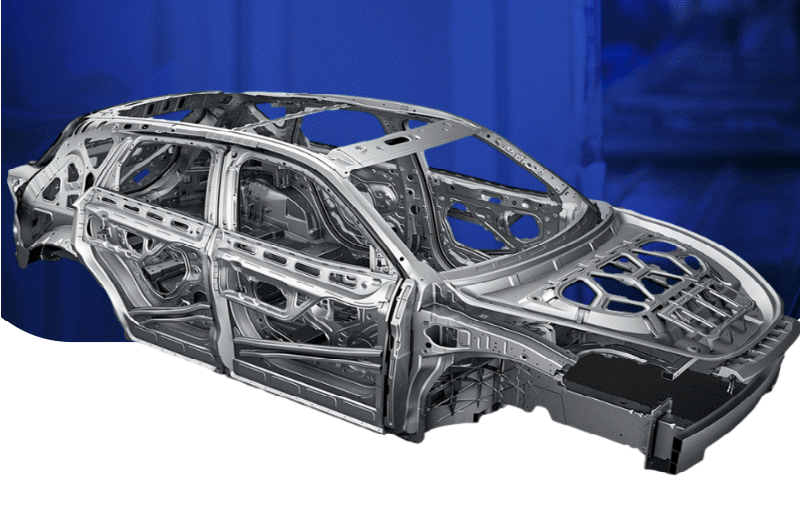

Applications High-strength automotive components: automotive structural components such as body panels (e.g. doors, hood, trunk lid), chassis parts, and reinforcement elements. The high strength of 5182-H19 helps enhance the structural integrity of these components while maintaining relatively low weight.

2. 5182 h19 Aluminum has Good Formability

Despite strain hardening in the H19 temper, 5182 aluminum retains good formability. It can bend, shape, and form complex parts without any difficulty. This combination of high strength and formability is particularly valuable in applications requiring both.

Application Formed and Stamped Parts: A variety of formed and stamped parts used in automotive manufacturing, including complex shapes such as brackets, brackets, and stiffeners. The formability of 5182-H19 allows the production of complex parts.

3. 5182 h19 Aluminum Plate Reduces Weight

Use 5182-H19 aluminum sheet to help reduce weight in automotive and transportation applications. Reducing weight can improve fuel efficiency and overall vehicle performance.

Examples of weight-saving applications: lightweight components in vehicles, including trucks, trailers, and railcars. The weight savings achieved with the 5182-H19 help improve fuel efficiency and payload capacity.

4. 5182 h19 Aluminum Plate Cold Processing Stability

The H19 temper condition provides stable mechanical properties, which is critical for applications where the material will undergo cold working or forming operations.

Examples of cold worked and fabricated structural applications: Structural elements in construction and building projects such as curtain walls, facades, and building cladding. The stability of the mechanical properties of 5182-H19 after cold working makes it suitable for these applications.

5. 5182 h19 Aluminum Plate is Cost-Effective

In some cases, the 5182-H19 aluminum plate can be a cost-effective option because it combines strength and formability, helping to reduce material waste during the molding and manufacturing process.

Examples of cost-effective manufacturing applications: Any application that requires strong and formable components while aiming for cost-effective production. This can include general sheet metal manufacturing, where minimizing material waste is important to improve cost efficiency.

It is important to note that the choice of 5182-H19 or any other condition of 5182 aluminum should be based on the specific requirements of your project or application. Consider factors such as required strength, formability, corrosion resistance, and environmental conditions to ensure the temperature selected meets your performance standards.

Advantages of 5182-H19 aluminum plate

1. Good anti-rust performance and wide range of uses

Aluminum alloy itself has good oxidation resistance, and the 5182-H19 aluminum plate further improves the rust resistance on this basis. This means that it can be used for a long time in humid and corrosive environments without rusting easily, so it is widely used in shipbuilding, automobile bodywork, food processing and other fields.

2. 5182 aluminum contains a small amount of Si, has excellent welding performance, and has a low tendency to crack during welding.

The silicon content in aluminum alloys has an important impact on its welding properties. The small amount of silicon in the 5182-H19 aluminum plate can improve its welding performance after heat treatment, making the weld less prone to cracks, thus improving the quality and efficiency of welding. This makes 5182-H19 aluminum plates very popular in industries that require welding processing, such as car body manufacturing and oil tank manufacturing.

3. Excellent corrosion resistance, high tensile strength and high yield strength

5182-H19 aluminum plate has excellent corrosion resistance, which means it can be used in harsh environments for a long time without being susceptible to corrosion. At the same time, it also has high tensile strength and high yield strength, allowing it to withstand large tensile and compressive forces without being easily deformed or broken. These characteristics make 5182-H19 aluminum plates widely used in aerospace, transportation and other fields.

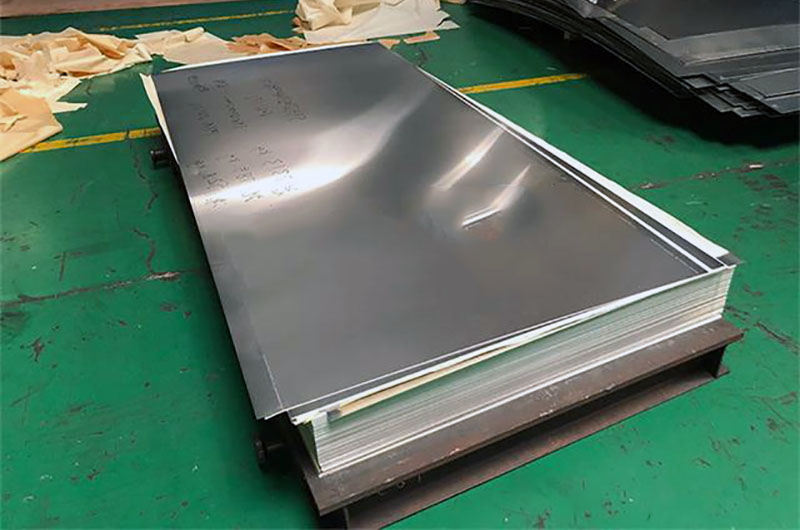

The 5182 aluminum plate produced by Haomei Aluminum has no defects on the surface, the pattern is smooth, and is of high quality. The 5182-H19 aluminum plate has undergone a precise production process to ensure that the surface is smooth and defect-free and the pattern is clear. This not only improves its aesthetics, but also ensures its quality stability and meets the requirements of various industrial standards and specifications. This makes it widely used in industries that require high-quality aluminum materials, such as electronic product casings, building decoration and other fields.

5182-H19 aluminum plate has important application value in many fields such as automobile manufacturing, aerospace, and architectural decoration due to its excellent performance.

5182 H19 Mechanical Properties

| Mechanical Property | Value |

| Yield Strength (0.2% offset) | Minimum 180 MPa |

| Tensile Strength | 230-310 MPa |

| Elongation | Minimum 2% |

| Fracture Elongation | Minimum 4% |

| Hardness (Brinell Hardness) | 55 HB |

Chemical composition of 5182 h19 aluminum sheet

| Element | Chemical composition (%) |

| Si | 0.2 |

| Fe | 0.35 |

| Cu | 0.5 |

| Mn | 0.0-0.5 |

| Mg | 4.0-5.0 |

| Cr | 0.1 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.1 |

| Al | Remainder |

Physical properties of 5182 h19 aluminum sheet

| Alloy | Temper | Thickness/mm | Tensile Strength Rm/MPa | Tensile Strength/MPa | Elongation % |

| 5182 | H36, H46 | >0.220 -0.300 | 265 ~340 | ≥270 | ≥3 |

| >0.300 -0.500 | 265 ~340 | ≥270 | ≥4 | ||

| 5182 | H18, H38, H48 | >0.220 -0.300 | 330 | ≥285 | ≥3 |

| >0.300-0.500 | ≥330 | ≥285 | ≥4 | ||

| 5182 | H19, H39, H49 | >0.220-0.300 | ≥340 | ≥295 | ≥3 |

| >0.300 -0.500 | ≥340 | ≥295 | ≥4 |

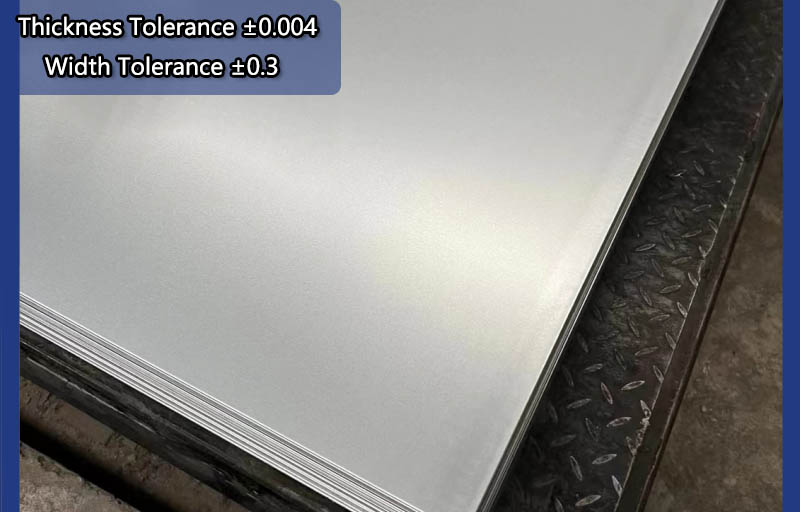

5182 h19 Aluminum Plate Specifications

| Property | Specification |

| Thickness (mm) | 0.250-0.500 |

| Width (mm) | 800-1200 |

| Thickness Tolerance | ±0.004 |

| Width Tolerance | ±0.3 |

- Thickness: Various thicknesses are available, from thin gauge to thicker sheets/sheets, depending on specific requirements.

- Dimensions: Dimensions of 5182 H19 Aluminum Sheet/Plate can vary according to customer needs and can be customized accordingly.

5182 H19 Aluminum Plate Typical Thicknesses

| Product | Thickness (mm) |

|---|---|

| 5182 H19 Aluminum Plate | 0.5 |

| 5182 H19 Aluminum Plate | 1 |

| 5182 H19 Aluminum Plate | 2 |

| 5182 H19 Aluminum Plate | 3 |

| 5182 H19 Aluminum Plate | 4 |

| 5182 H19 Aluminum Plate | 5 |

| 5182 H19 Aluminum Plate | 6 |

| 5182 H19 Aluminum Plate | 8 |

| 5182 H19 Aluminum Plate | 10 |

| 5182 H19 Aluminum Plate | 12 |

| 5182 H19 Aluminum Plate | 15 |

| 5182 H19 Aluminum Plate | 20 |

| 5182 H19 Aluminum Plate | 25 |

| 5182 H19 Aluminum Plate | 30 |

| 5182 H19 Aluminum Plate | 40 |

| 5182 H19 Aluminum Plate | 50 |

5182 h19 Aluminum Plate Applications

Q: In what fields is the 5182 aluminum plate widely used?

A: 5182 aluminum sheet is widely used in the field of transportation. The following are some common application areas:

- Automobile Industry: used in the manufacture of automobile body panels, four doors two covers, and other parts.

- Shipbuilding Industry: used as structural parts such as outer plates and decks of ship hulls.

- Tank car Manufacturing: used to manufacture parts such as tank car lids.

- Packaging Industry: It is often used to process can lids.

- Other Fields: It can also be used to manufacture storage tanks, fuel tanks, sheet metal parts of vehicles, etc.

Q: What is the Typical application of 5182-H19 aluminum alloy?

A: The 5182-H19 aluminum alloy is mainly used in the packaging market and the automotive industry.

With the development of the beverage industry and the replacement of old packaging materials, the main application of 5182-H19 aluminum alloy is to make pull rings for beverage cans.

As a high-magnesium alloy, 5182 is a non-heat-treatable alloy and can also be used to manufacture fuel tanks, oil pipes, transportation vehicles, ship sheet metal parts, etc.

Q: Why is 5182-H19 aluminum alloy suitable for beverage can tabs?

A: 5182-H19 aluminum alloy has good formability, corrosion resistance, and weldability, which is an ideal choice for pull tabs. It has moderate strength and can easily open beverage cans. The alloy's properties, such as its lightweight, good machinability, and high surface finish, make it suitable for tab pull applications.

- Canning Rings: 5182 aluminum sheet (usually in H19 condition) is commonly used for canning rings.

- Can Ends: Can ends are usually made from 3104 aluminum sheets or 5052 aluminum sheets, 5182 aluminum sheets can also be used for this purpose.

- Tanks: Tanks are usually made of aluminum alloys such as 3104 or 5052.

- Examples: beer cans, beverage cans, eight-treasure porridge, food cans.

The can body is usually made of 3104 h19 material, and the lid is made of 5052 h19 or 5182 h19 material, which can also be made into a pull ring. The lid needs to be harder than the body, and the hardness of 5182 h19 aluminum meets the requirements perfectly.

Q: Why are aluminum cans preferred in the beverage packaging industry?

A: Aluminum cans have several advantages in the beverage packaging industry.

- Lightweight, heat-resistant, good electrical conductivity, odorless and non-toxic, excellent printing effect.

- Aluminum cans are also highly recyclable, promoting sustainable packaging solutions.

- Aluminum cans have huge growth potential and are increasingly adopted by the food and beverage industry owing to growing concerns about environmental issues and demand for green packaging materials that ensure human health.

Q: Why is 5182-H19 aluminum alloy suitable for the automotive industry?

A: 5182 aluminum plate has excellent strength, corrosion resistance, and machinability. It can meet the requirements of automobile manufacturing, provide lightweight, safety, and environmental protection performance, and also help to reduce fuel consumption and reduce exhaust emissions of automobiles.

5182-H19 aluminum alloy can be used as the material of automobile body panels, four doors, and two covers.

In the automotive industry, 5182 aluminum sheets are commonly used in the following positions:

- Automobile body panels: 5182 aluminum sheets can be used to manufacture automobile body panels, including doors, roofs, side walls of compartments, etc. Its high strength and excellent formability make the body structure lighter and meet the requirements of automobile safety and energy saving.

- Four doors and two covers: 5182 aluminum sheet can also be used to manufacture four doors and two covers (ie hood and trunk cover) of vehicles. It has good corrosion resistance and surface quality, which can provide a good appearance and durability.

- Fuel tank: Due to its excellent corrosion resistance and sealing performance, The 5182 aluminum plate is widely used in the manufacture of automobile fuel tanks. It can effectively prevent fuel leakage and corrosion, and improve the safety and reliability of the fuel system.

- Other parts: 5182 aluminum sheet can also be used to make other sheet metal parts of the car, such as chassis cover panels, hood lining panels, interior panels, etc. Its lightweight and high-strength properties make vehicles more energy-efficient and efficient.

Note: Exact dimensions, tolerances, and availability may vary by manufacturer or supplier. It is recommended to consult a reliable aluminum supplier for accurate information on the size and availability of 5182 H19 Aluminum Sheet/Sheet.

Hot Topics of 5182 Aluminum Plate

- 5182 H19 Aluminum Sheet Coil for Cans End

- 5182 H19 Deep Drawing Aluminum Plate

- 5182 H19 Aluminium for Ring-pull Can Cap Stock

- 5182-h19 Aluminum Sheet for Can Pull Tab

- alloy 5182 H19 Food Grade Roller Aluminium Coated Sheet 0.35mm for Pull Ring

- aluminium for Packaging 5182 H19

- aluminum Sheet Coil 5182 H19 for End Stock And Tab

- 5182 H19 Aluminum Sheet Coil for Drink Can

-

5182 Aluminum Plate Sheet

5182 aluminum plate, which is a deformed alloy with good corrosion resistance, good weldability, corrosion resistance, medium strength and cold working properties.

-

5182 h111 Aluminum Plate Sheet

5182 H111 is a non-heat treatable aluminum alloy with a good combination of formability and strength. 5182 H111 aluminum plate has high corrosion resistance and is very suitable for tank truck materials.

-

5182 o Aluminum Plate Sheet

5182 O aluminum plate is used for car doors, fenders, and engine hoods. It has good stamping effect, corrosion resistance, good formability, and high safety factor.

-

5182 Aluminum Plate for Tanker

Specifically designed for tankers, our 5182 aluminum plate offers excellent corrosion resistance and high strength for reliable leak and splash protection.

-

Aluminum Plate for Tanker Body

Tanker Body complies with various regulations, standards, and certifications related to safety, structural integrity, leak prevention, and cargo handling.

-

5182 Automotive Aluminum Plate Sheet

5182 Automotive Aluminum Plate Sheet has a flat shape, high quality, good corrosion resistance, good weight reduction, and energy-saving effects, and its safety and comfort are better provided.

-

Automotive Aluminum Plate for Car Door

The stamping effect of the Haomei Aluminum 5182 alloy aluminum plate is good, and the customer feedback is that the aluminum plate has no cracks after stamping.

People also searched for Aluminum Plate

-

3104 Aluminum Plate Sheet

The performance of the 3104 aluminum plate is stable, the surface is smooth, smooth, and free of defects, and the tolerance is strictly controlled to meet the standard.

-

3104 h19 Aluminum Plate Sheet

3104 h19 Aluminum Plate Sheet has precise specifications, good shape, high strength, easy processing, and good deep drawing performance.

-

3105 Aluminum Plate Sheet

3105 aluminum alloy is stronger than 1100 and 3003 alloys. 3105 aluminum sheet is often used in street signs, building siding and bottle caps.

-

3004 Aluminum Plate Sheet

3004 aluminum is similar to 3003 aluminum, but it is stronger than 3003 alloy. 3004 aluminum also has good formability, good processability, excellent corrosion resistance and drawing characteristics.

-

3004 h19 Aluminum Plate Sheet

3004 H19 is a non-heat treatable aluminum alloy suitable for chemical and food contact applications, common ones such as beverage cans.