5454 Aluminum Plate Sheet

Temper: H32/H34/H111 ASTM B209/AMS 4011

5454 aluminum-magnesium alloy is an alloy in the wrought aluminum-magnesium series (5000 or 5xxx series). It is closely related to 5154 aluminum alloy.

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

5454 Aluminum is an aluminum-magnesium alloy that combines medium to high strength and excellent weldability.

5454 Aluminum is a wrought alloy in that it can be formed by rolling, extruding, and forging (although forging is uncommon), but it cannot be cast.

5454 Aluminum Plate Specifications

When referring to 5454 aluminum sheet or plate, it usually refers to a flat sheet of aluminum of a specific thickness and size. Aluminum plates and sheets are available in various sizes and thicknesses to meet different requirements.

5454 Aluminum Plate Usual Format

- ASTM B209: Standard Specification for Aluminum and Aluminum Alloy Plates and Plates

- AMS 4011: Aluminum alloy plate and plate, 2.7Mg - 0.12Cr (5454-H32), strain hardening, quarter hard and stabilized

5454 Aluminum Plate Common size

5454 aluminum sheet is available in a variety of sizes depending on the specific requirements of the application. Some common sizes include:

- Length: Typically ranges from 2, 000 mm (6.56 ft) to 6, 000 mm (19.69 ft) or more

- Width: Typically between 1, 000 mm (3.28 ft) and 2, 500 mm (8.20 ft) or wider

- Thickness can range from 0.2 mm (0.008 in) to several inches, depending on the specific needs of the project.

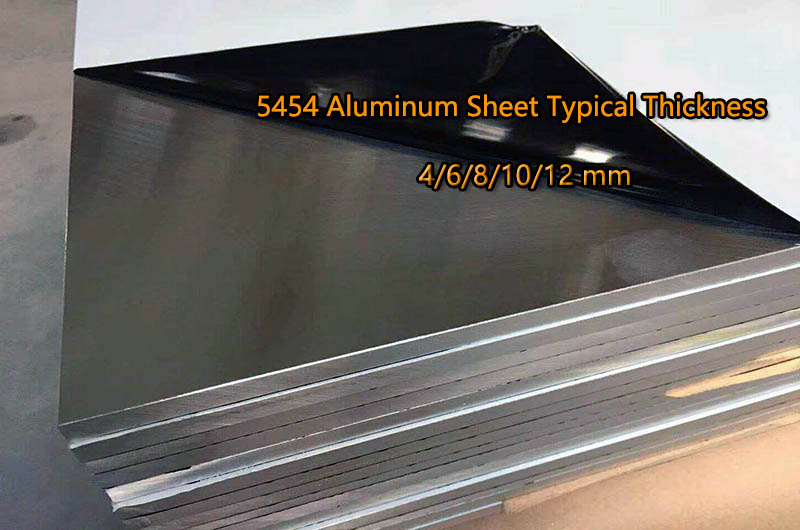

The thickness of the 5454 aluminum plate can vary depending on the intended application and specific requirements.

| Alloy | Millimeter Measurement | Inch Equivalent |

|---|---|---|

| 5454 Aluminum Plate | 4 mm | 0.157 in |

| 5454 Aluminum Plate | 6 mm | 0.236 in |

| 5454 Aluminum Plate | 8 mm | 0.315 in |

| 5454 Aluminum Plate | 10 mm | 0.394 in |

| 5454 Aluminum Plate | 12 mm | 0.472 in |

Other thicknesses are also available upon request.

Typical Temper

5454 aluminum sheet is available in a variety of tempers, including:

- H32: Strain hardened and stabilized tempered for higher strength and formability.

- H34: Strain hardened and partially annealed and tempered, offering moderate strength and improved mechanical properties compared to H32.

- H111: Stress-relief tempering is obtained by heating and rapidly cooling the material, improving formability and corrosion resistance.

These specifications, dimensions, thicknesses, and tempers are common but may vary according to manufacturer, supplier, and specific project requirements. It is always advisable to consult the supplier or refer to the relevant standards for accurate information on the options available.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.

Equivalent To 5454 Aluminum

- Alloy 5454

- AA5454

- AlMg3Mn

- EN AW-5454

- A95454

- 3.3537 (European designation)

5454 Aluminum Sheet Mechanical Properties

| Property | Minimum Value |

|---|---|

| Tensile Strength (σb) | ≥215 MPa |

| Conditional Yield Strength (σ0.2) | ≥85 MPa |

| Elongation at 10% (δ10) | ≥10% |

| Elongation at 5% (δ5) | ≥12% |

Typical Material Properties for 5454 Aluminum Alloy

| Property | Value |

|---|---|

| Density | 2.69 g/cm³ |

| 168 lb/ft³ | |

| Young's Modulus | 70 GPa |

| 10 Msi | |

| Electrical Conductivity | 34% IACS |

| Ultimate Tensile Strength | 240-300 MPa |

| 35-44 ksi | |

| Thermal Conductivity | 130 W/m-K |

| Thermal Expansion | 22.3 μm/m-K |

5454 Aluminum Alloy Chemical Composition

| Element | Composition Range |

|---|---|

| Aluminium | 94.5% to 97.1% |

| Chromium | 0.05% to 0.20% |

| Copper | 0.1% max |

| Iron | 0.4% max |

| Magnesium | 2.4% to 3.0% |

| Manganese | 0.5% to 1.0% |

| Silicon | 0.25% max |

| Titanium | 0.2% max |

| Zinc | 0.25% max |

| Residuals | 0.15% max |

Typical 5454 Aluminum Plate

The designations "H34", "H32" and "H111" refer to the different tempers of 5454 aluminum sheet. The tempered condition of aluminum alloys indicates the specific heat treatment and mechanical properties of the material.

5454 h34 Aluminum Plate

- H34 is a strain hardened and partially annealed temper.

- 5454 h34 is a medium strength temper with improved mechanical properties compared to the O (annealed) temper.

- H34 has good formability and high corrosion resistance.

- Typical applications for 5454 h34 Aluminum Plates include automotive panels, storage tanks, and marine components.

5454 h32 Aluminum Plate

- H32 is a strain hardened and stable state.

- 5454 h32 has slightly higher strength compared to H34 and improved formability compared to H28.

- 5454 H32 has good corrosion resistance and is often used in structural and marine applications.

5454 h111 Aluminum Plate

- H111 is a stress relief temper obtained by heating the material above the recrystallization temperature followed by rapid cooling.

- 5454 h111 has good formability and higher corrosion resistance compared to O temper.

- 5454 H111 is typically used in applications requiring high strength and excellent welding characteristics, such as pressure vessels and marine structures.

NOTE: Specific mechanical properties and tolerances may vary for each temper.

What is 5454 Aluminum Used for?

Aluminum plates and panels are versatile and can be cut, shaped, and shaped to specific requirements. They are commonly used in applications such as structural components, automotive body panels, truck trailer panels, marine structures, and industrial equipment.

Like 5154, 5454 aluminum is often used in welded structures such as pressure vessels and ships.

5454 Aluminum is a high-strength alloy commonly used in a variety of industries, including automotive and marine applications. It has excellent corrosion resistance and weldability, making it suitable for environments requiring resistance to salt water and harsh conditions.

Certainly, here are the reasons for choosing the 5454 aluminum plate in the corresponding applications:

1. 5454 Marine Aluminum Plate

Reasons for Choosing 5454 Marine Aluminum Plate:

- Excellent Corrosion Resistance: 5454 aluminum's exceptional corrosion resistance makes it well-suited for marine environments.

- Durability: It ensures the longevity of boat hulls and reduces maintenance.

- Lightweight: Aluminum's lightweight properties contribute to better fuel efficiency in boats.

2. 5454 Aluminum Plate for Automotive Fuel Tanks

Reasons for Choosing 5454 Aluminum Plate:

- Corrosion Resistance: It prevents fuel leaks and corrosion, ensuring safety.

- Formability: 5454 aluminum can be shaped into complex tank designs.

- Weight Savings: Lightweight material contributes to fuel efficiency.

3. 5454 Aluminum for Pressure Vessels

Pressure Vessels Reasons for Choosing 5454 Aluminum:

- Corrosion Resistance: Crucial for withstanding corrosive chemicals.

- Weldability: It allows for the fabrication of intricate pressure vessel designs.

- Durability: Long-lasting in harsh chemical environments.

4. 5454 Aluminum for Structural Components

Reasons for Choosing 5454 Aluminum Plate:

- Lightweight Strength: Provides structural integrity without excessive weight.

- Corrosion Resistance: Important in aerospace environments.

- Formability: Allows for complex aerospace component designs.

5. 5454 Aluminum for Heat Exchangers

Reasons for Choosing 5454 Aluminum Plate:

- Good Thermal Conductivity: Enhances heat transfer efficiency.

- Corrosion Resistance: Resists damage from coolants.

- Formability: Enables the production of efficient heat exchanger designs.

6. 5454 Aluminum for Offshore Structures

Reasons for Choosing 5454 Aluminum Plate:

- Saltwater Resistance: Vital for withstanding harsh marine conditions.

- Durability: Long-lasting in saltwater environments.

- Weight Efficiency: Helps reduce overall structure weight.

7. 5454 Aluminum for Architectural Applications

Reasons for Choosing 5454 Aluminum Plate:

- Aesthetics: Offers a sleek, modern appearance.

- Corrosion Resistance: Withstands outdoor exposure.

- Lightweight: Facilitates easier installation.

8. 5454 Aluminum for Welded Structures

Reasons for Choosing 5454 Aluminum:

- Weldability: Good weldability simplifies fabrication.

- Corrosion Resistance: Ensures welded structures remain corrosion-free.

- Strength: Provides adequate strength for welded components.

9. 5454 Truck Trailers Aluminum Plate

Reasons for Choosing 5454 Aluminum:

- Weight Savings: Helps reduce the overall weight of the trailer.

- Corrosion Resistance: Essential for withstanding road and environmental conditions.

- Durability: Ensures a longer service life for trailers.

10. Marine Equipment:

Reasons for Choosing 5454 Aluminum:

- Saltwater Resistance: Critical for marine equipment longevity.

- Weight Efficiency: Lightweight for improved performance.

- Corrosion Resistance: Protects components in marine environments.

-

5454 Aluminum Plate for Tankers

To ensure the safety and reliability of these tankers, the choice of materials is of utmost importance. Among the various materials available, 5454 aluminum plate has emerged as a popular choice due to its exceptional properties and benefits.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

In each of these applications, the choice of 5454 aluminum plate is driven by its specific attributes that align with the requirements of the application, such as corrosion resistance, formability, strength, and weight considerations.

These are just a few examples of the many applications of 5454 aluminum. Its versatility combined with desirable mechanical and corrosion resistance properties make it a popular choice across several industries.

5454 Aluminum Plate VS Other 5000 Series Alloy Plate

The 5000 series aluminum alloys, including 5454, are known for their excellent corrosion resistance, moderate strength, and versatility. Each alloy in this series has specific properties and characteristics that make it suitable for a variety of applications. Here's how the 5454 aluminum plate compares to some other common alloys in the 5000 series:

5454 Aluminum vs 5052

Corrosion Resistance: Both 5454 and 5052 have good corrosion resistance, but 5454 is slightly more resistant to saltwater corrosion, making it the first choice for marine applications.

Strength: The strength of the 5454 aluminum plate is about 20% higher than that of the 5052 aluminum plate. 5454 has higher strength than 5052, making it suitable for applications requiring greater structural integrity.

Formability: 5052 is known for its excellent formability, making it a better choice for applications requiring complex shapes.

5454 Aluminum vs 5083

Weldability: Both alloys can be welded, but 5454 is generally more suitable for welding because it is less susceptible to weld cracking.

Corrosion Resistance: 5083 is known for its excellent resistance to seawater corrosion, making it a first choice for marine and offshore applications. 5454 also has good corrosion resistance but is considered slightly inferior in this regard.

Strength: 5083 has higher tensile and yield strengths compared to 5454, making it suitable for applications requiring higher strength properties.

5454 Aluminum vs 5754

Strength: Compared to 5754, 5454 has slightly higher tensile and yield strengths, making it suitable for applications where strength is the primary concern.

Formability: 5754 is known for its excellent formability, which is advantageous in applications requiring complex shapes.

Corrosion Resistance: Both 5454 and 5754 offer excellent corrosion resistance, particularly in marine and industrial environments. They are often used interchangeably in similar applications.

5454 Aluminum vs 5086

Corrosion Resistance: 5086 has strong corrosion resistance, especially in saltwater environments. It is commonly used in shipbuilding and offshore structures. Although 5454 has good corrosion resistance, it is generally not the first choice for extremely corrosive environments.

Strength: 5086 has higher strength properties compared to 5454, which can be advantageous in structural applications.

5454 Aluminum vs 5005

Corrosion Resistance: Both 5454 and 5005 have good corrosion resistance. However, 5005 is not as corrosion resistant as 5454, especially in marine or saltwater environments. In this case, 5454 is preferred.

Strength: Compared to 5005, 5454 has higher strength. If your application requires moderate strength and good corrosion resistance, 5005 may be suitable. Still, for applications requiring higher strength, the 5454 is a better choice.

Formability: 5005 is known for its excellent formability, making it a first choice for applications requiring complex shapes, such as automotive body panels and architectural trim. 5454, while still formable, may not be as easy to form as 5005.

5454 Aluminum vs 5182

Corrosion Resistance: Both 5454 and 5182 have good corrosion resistance, and they are often used in similar applications. However, 5454 may have a slight advantage in saltwater or marine environments.

Strength: 5182 generally has higher tensile and yield strengths compared to 5454. This makes 5182 a better choice for applications where strength is a primary consideration, such as the manufacture of beverage can lids.

Formability: Both 5454 and 5182 have good formability, but the choice between them may depend on the specific forming requirements of your application. Consider the complexity of the shapes you need to produce.

Weldability: Both alloys can be welded, but 5454 is generally more suitable for welding because it is less susceptible to weld cracking. If welding is a critical aspect of your application, 5454 may be a better choice.

1. If you need excellent corrosion resistance (especially in marine environments) and moderate strength, 5454 is a good choice.

2. If you require excellent formability and corrosion resistance, 5005 may be more suitable, especially for applications such as automotive body panels.

3. If your application requires higher strength and good corrosion resistance, 5182 may be the first choice, especially for beverage can lid manufacturing.

Ultimately, the choice between these alloys should be based on your specific application requirements, including the environment to which they will be exposed, required strength, formability needs, and any welding considerations.

5454 Aluminum Plate Production Process

The production process of the 5454 aluminum plate, like most aluminum alloys, involves several key steps. Aluminum alloy 5454 is a high-strength, non-heat-treatable alloy primarily used in structural applications, and it is known for its excellent corrosion resistance. Here's a simplified overview of the production process for 5454 aluminum plates:

- Aluminum Smelting: The process begins with aluminum smelting, where aluminum oxide (alumina) is extracted from bauxite ore using a refining process. The alumina is then reduced to aluminum metal in an electrolytic cell using an electric current.

- Alloying: To create 5454 aluminum alloy, various elements are added to the molten aluminum during the smelting process. The primary alloying elements in 5454 are magnesium (Mg) and small amounts of manganese (Mn) and chromium (Cr).

- Casting: After alloying, the molten aluminum is cast into large logs, typically through a continuous casting process. These logs are also known as billets.

- Preheating: The aluminum billets, are preheated to a specific temperature to make them more malleable for subsequent processing.

- 5454 Aluminum Hot Rolling: The preheated aluminum billets are hot-rolled, to reduce their thickness and shape them into plates. This involves passing the aluminum billets through a series of rollers to gradually reduce the thickness.

- 5454 Aluminum Cold Rolling (Optional): Depending on the required plate thickness and properties, cold rolling may be performed after hot rolling to further reduce the thickness and improve the surface finish. Cold rolling also enhances the mechanical properties of the aluminum.

- 5454 Aluminum Heat Treatment (Optional): Some aluminum alloys, such as 5454, are non-heat-treatable, which means they do not require heat treatment to achieve their final properties. However, certain processes like stress relieving or annealing may be performed if necessary for specific applications.

- 5454 Aluminum Finishing: After rolling and any necessary heat treatment, the aluminum plates are cut to the desired dimensions and subjected to surface treatment processes. Surface treatments can include cleaning, chemical treatments to enhance corrosion resistance, and surface inspection for quality control.

- Quality Control: Throughout the entire production process, quality control measures are implemented to ensure that the aluminum plates meet the required specifications for thickness, mechanical properties, and surface finish.

- Packaging and Shipping: Once the aluminum plates have passed all quality checks, they are packaged for shipment to customers. Packaging may involve protective materials to prevent damage during transit.

It's important to note that the specific details of the production process can vary depending on the manufacturing facility and the desired properties of the 5454 aluminum plates. Additionally, environmental and safety standards are typically adhered to throughout the production process to minimize environmental impact and ensure worker safety.

People also searched for Aluminum Plate

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5754 h22 Aluminum Plate Sheet

5754 h22 aluminum refers to H22 tempered 5754 alloy. 5754 h22 Annealed to quarter hardness. Generally speaking, 5754 h22 alloy is widely used in welded structures, vehicles, marine applications, etc.

-

5754 h111 Aluminum Plate Sheet

5754 H111 aluminum plate is a rust-proof aluminum plate with good corrosion resistance. 5754 H111 aluminum has a wide range of uses and is mainly used in fields that require corrosion resistance such as ships and construction to improve the service life and safety of ships.