5454 h32 Aluminum Plate Sheet

Stable Performance Competitive Prices

5454 h32 aluminum plate refers to a specific form of 5454 aluminum alloy that has been processed into the h32 state.

5454 H32 is an aluminum alloy designation that indicates specific properties of the material.

5454: This number represents the alloy composition. This refers to aluminum-magnesium alloys that contain specific proportions of alloying elements. The 5454 alloy contains about 95.7% aluminum, 2.7% magnesium, 0.8% manganese, and trace amounts of other elements.

H32: The "H32" designation indicates the temper or temper of the aluminum alloy. It is the code of the Aluminum Association and describes the manufacturing history and mechanical properties of the material. In this case, "H32" means strain hardened and steady state, with a quarter hard temper. This means that the material has undergone a cold working process to increase its strength and hardness.

The combination of alloy 5454 and temper H32 makes this material suitable for a variety of applications requiring moderate strength, excellent corrosion resistance, and good formability. Some common uses for 5454 H32 aluminum include marine components, automotive components, pressure vessels, and building structural components.

5454 H32 aluminum belongs to the 5xxx series of aluminum alloys, known for its excellent corrosion resistance and weldability. The primary alloying element in 5454 aluminum is magnesium, which increases strength and toughness. Other elements present in smaller amounts include silicon and iron, which help improve the alloy's mechanical properties.

5454 h32 aluminum properties

1. Lightweight

5454 H32 aluminum has a density of approximately 2.7 g/cm3 and is approximately one-third the weight of steel, making it an excellent choice for weight-saving applications such as transportation and aerospace.

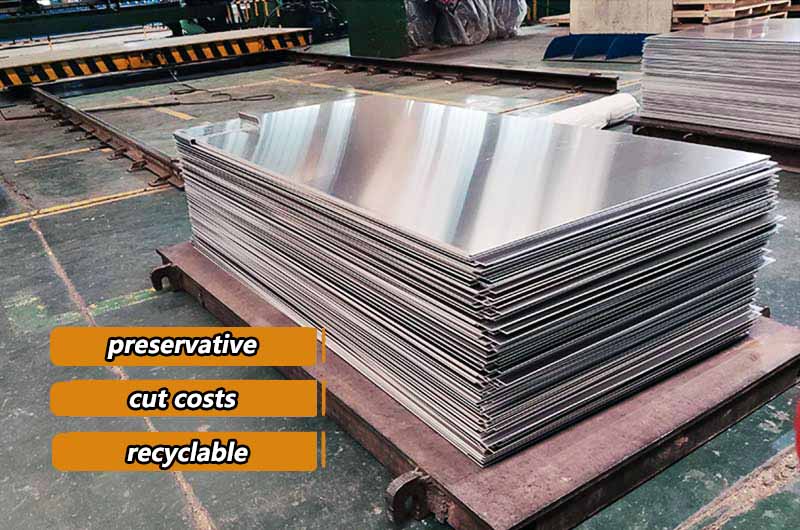

2. Corrosion resistance

The alloy's excellent corrosion resistance, especially in marine environments, ensures a long service life and minimal maintenance requirements, reducing life cycle costs and increasing product reliability.

3. High intensity

5454 H32 aluminum offers a good balance between strength and ductility, allowing for the creation of strong structures and components without sacrificing formability or machinability.

4. Recyclability

Like all aluminum alloys, 5454 H32 aluminum is fully recyclable with no loss of quality or performance. Recycling scrap aluminum consumes significantly less energy than primary production, making it an environmentally sustainable material choice.

5. Cost-effectiveness

While aluminum alloys may have higher upfront costs compared to some alternative materials, their long-term benefits, including durability, corrosion resistance and recyclability, often result in overall cost savings over the life of the product.

5454 H32 Aluminum Data Sheet

Commonly used specifications for 5454 H32 aluminum plates generally meet industry standards and customer requirements. Here are some common specifications, sizes, and thicknesses of 5454 H32 aluminum sheet:

5454 H32 Aluminum Plate Typical Size

- Width: 48" (1.22m) or 60" (1.52m)

- Length: 96" (2.44m) or 120" (3.05m)

Depending on the manufacturer or supplier, custom sizes are also available.

5454 H32 Aluminum Plate Specifications

- ASTM B209: Standard Specification for Aluminum and Aluminum Alloy Plates and Plates

- AMS 4010: Aluminum Alloy Sheet and Plate, 2.5Mg - 0.25Cr (5454-H32)

- MIL-DTL-46027: Armor Plate, Aluminum Alloy, Weldable 5454

5454 H32 Aluminum Plate Typical Thicknesses

| Alloy | Thickness (inches) | Thickness (mm) |

|---|---|---|

| 5454 h32 Aluminum Plate | 0.125 | 3.175 |

| 5454 h32 Aluminum Plate | 0.188 | 4.775 |

| 5454 h32 Aluminum Plate | 0.25 | 6.35 |

| 5454 h32 Aluminum Plate | 0.375 | 9.525 |

| 5454 h32 Aluminum Plate | 0.5 | 12.7 |

These thicknesses generally apply to 5454 H32 aluminum plates, but it is important to note that specific suppliers or manufacturers may offer other thickness options. If you have specific requirements, it is recommended to consult the supplier or refer to the technical data sheet for all available thicknesses.

Production Tolerances of 5454 h34 Aluminum Plate

The production tolerances for 5454-H34 aluminum plates, like any other material, can vary depending on the specific manufacturer and the standards they adhere to. Keep in mind that these tolerances are approximate and should be verified with the manufacturer for your specific order:

5454 h32 Aluminum Plate Thickness Tolerance

Standard Thickness Tolerance: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) for common thicknesses.

Tighter Tolerances: Some manufacturers may offer tighter tolerances for precision applications, which could be as low as +/- 0.002 inches (0.051 mm).

5454 h32 Aluminum Plate Width Tolerance

Standard Width Tolerance: +/- 0.125 inches (3.175 mm) to +/- 0.250 inches (6.35 mm) for common widths.

Tighter Tolerances: Precision applications may require narrower width tolerances, which could be as low as +/- 0.062 inches (1.57 mm).

5454 h32 Aluminum Plate Length Tolerance

Standard Length Tolerance: +/- 0.25 inches (6.35 mm) to +/- 0.5 inches (12.7 mm) for common lengths.

Tighter Tolerances: For precise cutting and machining, you may request tighter length tolerances, such as +/- 0.125 inches (3.175 mm).

It's important to note that these are general guidelines, and actual tolerances can vary based on the manufacturer's equipment, capabilities, and the specific standards they adhere to. When ordering 5454-H34 aluminum plates, it's crucial to communicate your tolerance requirements with the manufacturer to ensure that you receive the desired product quality for your application.

5454 h32 aluminum sheet mechanical properties

The "H32" temper designation indicates that the aluminum has been strain hardened and stabilized to a stable state with a specific hardness. Mechanical properties of 5454 H32 aluminum typically include:

- Tensile strength: 240 MPa

- Yield strength: 130 MPa

- Elongation: 20%

5454 h32 aluminum sheet corrosion resistance

5454 H32 Aluminum provides excellent corrosion resistance in a variety of environments, including marine and industrial atmospheres. The presence of magnesium enhances its ability to withstand salt water exposure, making it particularly suitable for marine applications.

Applications of 5454 H32 aluminum

5454 Marine Grade Aluminum Sheet Plate

One of the main applications of 5454 H32 aluminum is in the shipbuilding industry. Its excellent corrosion resistance makes it ideal for the construction of hulls, decks and other structural components of ships and offshore platforms. The alloy's lightweight nature also helps improve fuel efficiency and overall performance.

5454 h112 Automotive Aluminum Sheet

In the automotive sector, 5454 H32 aluminum is used to make components such as body panels, fuel tanks and chassis components. Its combination of strength, formability and corrosion resistance make it a top choice for improving fuel economy and reducing vehicle weight.

5454 O H111 Oil Tanker Aluminum Sheet Plate

Haomei Aluminum can produce high-strength, corrosion-resistant, recyclable 5454 tank truck aluminum plates that meet EN14286, ASTM B209 standards.

5454 H34 H112 O Aerospace Grade Aluminum Sheet plate

5454 H32 Aluminum is not as common as other industries, but it is used to make aircraft parts that require a combination of strength, corrosion resistance, and lightweight properties.

Aluminum 5454 h32 for transportation

5454 H32 aluminum is widely used in a variety of transportation applications, including truck trailers, rail vehicles, and cargo containers. Its high strength-to-weight ratio allows heavy loads to be transported while ensuring structural integrity and durability.

Aluminum 5454 h32 for Architecture and Construction

Due to its beauty, durability and corrosion resistance, 5454 H32 aluminum is used in construction applications such as roofs, facades and structural elements. Its lightweight nature simplifies installation and reduces the overall load on the building.

-

5454 Aluminum Plate for Tankers

To ensure the safety and reliability of these tankers, the choice of materials is of utmost importance. Among the various materials available, 5454 aluminum plate has emerged as a popular choice due to its exceptional properties and benefits.

-

5454 aluminum plate exhibits excellent corrosion resistance, especially in marine environments. It effectively resists the corrosive effects of salt water and seawater, making it ideal for prolonged exposure to these conditions.

Aluminum 5454 h32 vs h34

While the H32 and H34 tempers of 5454 aluminum plates have some similar applications, the H34 temper is often chosen for more demanding applications requiring higher strength and enhanced structural performance.

5454 H32 and 5454 H34 aluminum sheets are the same alloy (5454) but differ in temper or temper. Here's how they compare:

5454 H32 Aluminum Plate

- Marine Applications: Due to its excellent corrosion resistance, 5454 H32 aluminum sheet is commonly used in the construction of ships, hulls, and other marine components.

- Automotive industry: Used in the manufacture of automotive panels, body structures, and other components that require high corrosion resistance.

- Pressure vessel: 5454 H32 aluminum plate is suitable for manufacturing storage tanks, pipelines, and other pressure vessels that require high corrosion resistance and strength.

- Structural Applications: It can be used for structural components in buildings, including bridges, building facades, and supports.

- General Applications: The combination of medium strength, good formability, and corrosion resistance makes the 5454 H32 Aluminum Sheet suitable for a range of general applications such as sheet metal fabrication, signage, and architectural elements.

5454 H34 Aluminum Plate

- High Strength Applications: The 5454 H34 aluminum plate offers higher strength than the H32 temper, making it suitable for applications requiring greater load carrying capacity and structural integrity.

- Heavy Equipment: It is used in heavy truck bodies, trailers, and other transportation applications where durability and strength are critical.

- Industrial Applications: 5454 H34 Aluminum Sheet is used in industrial settings to manufacture equipment, storage tanks, and structural components that require high strength and corrosion resistance.

- Welded constructions: In welded constructions where joint strength is a critical factor, the H34 temper is usually preferred.

Aluminum 5454 h32 production process

1. welding

5454 H32 aluminum is easy to weld using various techniques such as gas metal arc welding (GMAW), gas tungsten arc welding (GTAW) and resistance welding. Correct surface preparation and selection of compatible filler materials are critical to ensuring high-quality welds and preventing defects.

2. Forming

The alloy has good formability and can be easily fabricated into complex shapes and configurations using processes such as bending, stretching and deep drawing. However, care must be taken to avoid excessive strain during molding to prevent cracking or deformation.

3. Mechanical processing

5454 H32 aluminum can be machined using traditional methods such as milling, drilling and turning. Carbide tools are recommended for optimal cutting performance and extended tool life. Adequate coolant lubrication is essential to dissipate heat and minimize tool wear.

5454 h32 Aluminum Plate Packaging

When packaging the 5454 H32 aluminum plate, there are several important considerations to ensure the safety and integrity of the 5454 H32 plate during storage, handling, and transportation. Here's what you should pay attention to:

- 1. Cleanliness: Before packaging, ensure that the 5454 h32 aluminum plates are clean and free of any contaminants such as dirt, oil, or debris. Any foreign objects may cause damage or corrosion.

- 2. Moving: When moving panels, use proper lifting equipment and techniques to avoid bending or warping. Care should be taken when handling to prevent surface damage.

- 3. Anti-Scratch: Aluminum is easily scratched. Use protective material such as foam board, corrugated paper, or bubble wrap to separate individual boards and prevent contact between them. Additionally, consider using corner guards to protect corners from impacts.

- 4. Stacking: If you need to stack multiple 5454 h32 boards, make sure they are stacked evenly to prevent warping. Use padding between boards to minimize friction and potential damage.

- 5. Packaging Materials: Choose appropriate packaging materials such as sturdy cardboard or wooden crates/boxes. Packaging materials should be able to support the weight of the panels and protect them from external factors.

- 6. Padding: Add padding material to the top and bottom of the stack to absorb shock and prevent damage from impacts during handling and shipping.

- 7. Secure Packaging: Use strapping, strapping material, or other means to securely close and secure packaging. Make sure to pack tightly to prevent the plate from moving within the container.

- 8. Label: Clearly label the package with basic information including the type of aluminum (5454 H32), quantity, weight, and any special handling instructions. Include contact information for easy identification and tracking.

- 9. Moisture Resistant: Aluminum corrodes easily. If there is a risk of moisture exposure during storage or transportation, consider using a desiccant or hygroscopic material within the packaging to prevent corrosion.

- 10. Quality control: Implement quality control measures to inspect packaged aluminum panels before transportation or storage to ensure that the packaging is intact and the panels are fully protected.

By paying attention to these precautions, you can help ensure that your 5454 H32 aluminum plate is packaged correctly and protected from damage during storage, handling, and shipping. Proper packaging is critical to maintaining the quality and integrity of your aluminum panels.

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.

People Also Searched about 5454 h32 Aluminum

- What is 5454 H32?

- What is 5454 grade aluminum?

- What is H32 aluminum?

- What is the difference between 5052 H32 and 5454 H32?

- 5454-h32 aluminum

- what does h32 aluminum mean

- what is 5052 h32 aluminum

People also searched for Aluminum Plate

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5754 h22 Aluminum Plate Sheet

5754 h22 aluminum refers to H22 tempered 5754 alloy. 5754 h22 Annealed to quarter hardness. Generally speaking, 5754 h22 alloy is widely used in welded structures, vehicles, marine applications, etc.

-

5754 h111 Aluminum Plate Sheet

5754 H111 aluminum plate is a rust-proof aluminum plate with good corrosion resistance. 5754 H111 aluminum has a wide range of uses and is mainly used in fields that require corrosion resistance such as ships and construction to improve the service life and safety of ships.