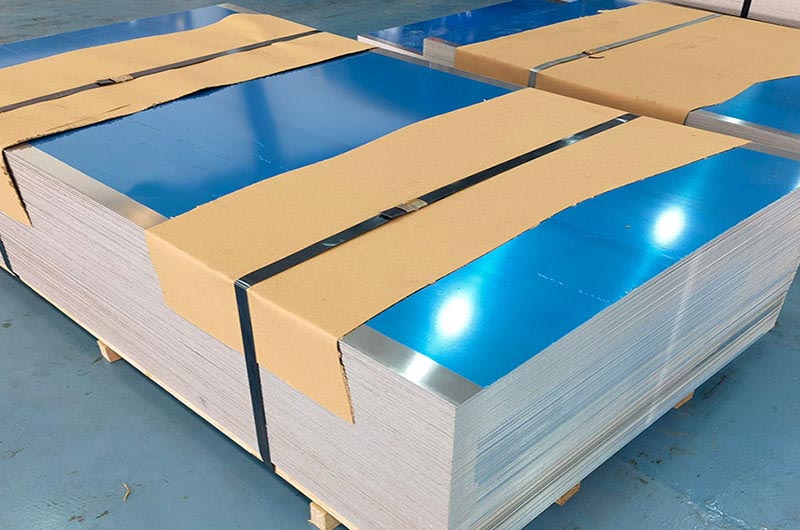

5754 h111 Aluminum Plate Sheet

Stable Performance Competitive Prices

5754 H111 is the tempered state of 5754 aluminum alloy, indicating the fully annealed strain hardened state

5754 H111 Aluminum is a specialty aluminum alloy commonly used in a variety of industries including marine, automotive and structural applications. The "H111" designation refers to the tempering process the aluminum undergoes to improve strength and stability.

5754 H111 Aluminum and 5754 H114 Aluminum are common alloys found in tread plates. For h111 tempered 5754 aluminum alloy, it shows high strength, excellent corrosion resistance, anodizing performance, surface treatment effect, cold workability, weldability, etc.

5754 aluminum alloy is known for its excellent corrosion resistance, making it suitable for applications in marine environments or other harsh conditions. It also has good weldability and machinability for easy fabrication and molding processes.

As for sheet and plate forms, aluminum alloy 5754 H111 is commonly used. Sheets are usually between 0.2 and 6.35mm thick, with sheets usually thicker, from 6mm to a few inches. The size of the sheet or plate can be varied according to the requirements of suppliers and customers.

Aluminum 5754 h111 Properties

Aluminum alloy 5754 H111 has a variety of properties and is suitable for a variety of applications. Here are some key features of the 5754 H111:

- Corrosion Resistance: 5754 H111 Aluminum has excellent corrosion resistance, especially in marine environments or other corrosive conditions. This characteristic makes it a popular choice for applications such as ship hulls, offshore structures, and chemical storage tanks.

- Strength: The H111 tempering process increases the strength and hardness of the aluminum alloy. 5754 H111 may not be as strong as some other alloys but still has good mechanical properties making it suitable for structural components, automotive components, and general engineering applications.

- Weldability: 5754 H111 aluminum alloy has good weldability, and can be easily connected with other aluminum alloys through various welding processes such as MIG, TIG, or resistance welding. This property benefits manufacturers and manufacturers.

- Formability and Machinability: Due to its good formability and machinability, this alloy can be easily shaped, bent, and shaped. It can be rolled into sheets, extruded, or stamped into various shapes without major issues. This makes it suitable for applications requiring complex shapes or complex designs.

- Surface Finish: 5754 H111 aluminum typically has a smooth, uniform surface finish, which is beneficial in applications where aesthetics are important. It can be further enhanced with various surface treatments such as anodizing, painting, or powder coating.

Note: These properties may vary slightly depending on specific suppliers, manufacturing processes, and conditions of use. It is always recommended to consult the manufacturer's data sheet or technical specification for accurate and up-to-date information on the properties of 5754 H111 aluminum alloy.

5754 h111 Aluminum Plate Specifications

- Common Thicknesses: The thickness of 5754 H111 aluminum sheet can vary according to specific requirements, typically 0.2 mm (0.008 in) to 6.35 mm (0.25 in). Other thicknesses are also available.

- Common Sizes: Aluminum Sheet 5754 H111 is available in a variety of sizes, common sheet sizes are 4ft x 8ft (1219mm x 2438mm) and 4ft x 10ft (1219mm x 3048mm). Custom sizes are also available for specific needs.

- Surface Finish: The surface of the 5754 H111 aluminum plate is typically in a honed condition, which refers to the natural finish obtained after the manufacturing process. It has not undergone any additional surface treatment such as anodizing or painting.

| Typical Alloy | 5754 Aluminum |

| Material Temper | H111 |

| Alloy Types | Sheet, Plate, Tread plate, Coil, Tread coil |

| Surface Pattern | Plain, Diamond, Big 5 bar, Small 5 Bar, 3 Bar, 2 Bar, Single Bar |

| Thickness (mm) | 0.1-500 |

| Width (mm) | 20-2650 |

| Length (mm) | Customize |

| Typical Product | Tread plate, Wind internal, Sound barriers, Shipbuilding, Transportation, Decoration materials, structural parts, etc |

5754 h111 Aluminum Plate Sheet Typical Mechanical Properties

| Temper | Thickness(mm) | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) |

| 5754 H111 | >0.20~0.50 | 129~240 | ≥80 | ≥12 |

| >0.50~1.50 | ≥14 | |||

| >1.50~3.00 | ≥16 | |||

| >3.00~6.00 | ≥18 | |||

| >6.00~12.50 | ≥18 | |||

| >12.50~100.00 | ≥17 |

5754 h111 Aluminum Plate Sheet Mechanical Properties

- Tensile strength σb (MPa): 165~265.

- The national standard for aluminum plate and strip (GB/T 3880-2006) is a unified standard for aluminum alloy plate and strip materials.

The Physical Properties of 5754 h111 Aluminum

| Property | Value |

| Density | 2.66g/cm³ |

| Melting Point | 595-645°C |

| Thermal Conductivity | 147W/m. K |

| Thermal Expansion | 24×10¯ ⁶/°C |

| Resistivity | 49nΩ.m |

| Modulus of Elasticity | 68GPa |

| Modulus of Rigidity | 26.5GPa |

Almg3 EN AW 5754 h111

EN AW 5754 h111 refers to the almg3 series aluminum EN AW 5754-h111 alloy. In other words, it is a typical non-heat-treated Al-Mg anti-rust alloy. almg3 en aw 5754 h111 achieved better performance due to the addition of the main component Mg.

Aluminum en aw 5754 h111 offers outstanding corrosion resistance, weldability, anodizing quality and higher mechanical properties, among others. Therefore, it is widely used in marine applications, vehicles, weldments, pedals, etc.

Al 5754 Chemical Composition

The chemical composition of aluminum alloy 5754 H111 generally includes the following elements:

Element Composition (%)

- Aluminum 97.3

- Magnesium 2.6

- Manganese 0.5

- Chromium 0.3

- Iron 0.4

- Silicon 0.25

- Copper 0.1

- Zinc 0.2

- Others 0.15 (max each)

Please note that the above information represents the general properties of 5754 H111 Aluminum Sheet and may vary by specific manufacturer and production standards. It is always recommended to consult the supplier's technical data or specifications for accurate information on the characteristics and dimensions of the 5754 H111 Aluminum Sheet.

5754 h111 Aluminum Plate Typical Applications

- Tread plate ( shows the beautiful surface patterns of diamond/ big 5 bar/ small 5 bar/ 3 bars, etc. )

- Decoration materials, cosmetics anodized, cans closures, various welding and structural parts

- Shipbuilding

- Rivets

- Vehicle bodies (tank truck, trailer, automobile, etc)

- Food processing and Pressure vessel

5754-H111 Aluminum Plate for Van Skin

A van is a type of vehicle that carries goods. It has a compartment with an independent closed structure. As an important part of its shelter from wind and rain, the skin is required to have a certain strength.

The application of van skin materials has broad market prospects. With the development and popularization of lightweight, aluminum materials are gradually replacing just now. Taking van truck skins as an example, 5754-H111 aluminum plates are mostly used.

Protects the body

overall lightweight

The overall appearance is also more beautiful

5 Bar 5754 H111 Tread Aluminum Plate

The aluminum plate with a pattern on the surface is called a patterned aluminum plate. The pattern has one rib, two ribs, three ribs, and five ribs. The 5754 tread aluminum plate is mostly aluminum-magnesium alloy patterned plate.

5 Bar 5754 H111 Tread aluminum plate is a widely used specification, which can be widely used in many fields such as ship deck, car deck, machinery, shipbuilding, transportation, construction, and other non-slip floors, decoration, and decoration.

5754 h111 Aluminum Plate for Stamping Parts

The 5754 aluminum plate belongs to the 5 series aluminum-magnesium alloy, and the most used state is h111. It has good toughness and is suitable for stamping. It is widely used in mechanical equipment, electronic industry, and other fields, and the processing technology is simple.

The 5-series aluminum plate has relatively low requirements for processing equipment and mechanical control in terms of mechanics, so it can be given priority when used in the stamping process. In addition, the thickness is also an important indicator that affects the stamping effect. The thicker the stamping is, the more difficult it is to stamp.

-

5754 Automotive Aluminum Plate Sheet

5754 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various automotive parts by rolling, bending, and stamping processes. It can be formed into complex shapes while maintaining its strength and integrity.

-

5754 Aluminum Plate for Tankers

5754 Aluminum Plate for Tankers Its light weight, corrosion resistance, durability and formability make it an ideal material for all types of tankers.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

5754 h111 Aluminum Plate Sheet heat treatment process

- 1) Homogenization annealing: heating at 440°C; holding for 12-14h; air cooling.

- 2) Rapid annealing: heating at 350~410℃; holding time 30~120min; air or water cooling.

- 3) High temperature annealing: heating at 350~420℃; when the thickness of the finished product is ≥6mm or <6mm, the holding time is 2~10min or 10~30min; air cooling.

- 4) Low temperature annealing: heating at 250~300℃ or 150~180℃; holding time is 1~2h, air cooling.

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5754 h22 Aluminum Plate Sheet

5754 h22 aluminum refers to H22 tempered 5754 alloy. 5754 h22 Annealed to quarter hardness. Generally speaking, 5754 h22 alloy is widely used in welded structures, vehicles, marine applications, etc.

People also searched for Aluminum Plate

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.