5754 h22 Aluminum Plate Sheet

Strict Quality Control Smooth and Flat Surface

The H22 temper condition of the 5754 aluminum plate involves strain hardening by controlled cooling after hot working. Compared to the annealed (O) condition, the 5754 H22 aluminum plate has higher strength, making it suitable for applications requiring higher mechanical properties.

5754 H22 aluminum refers to a 5754 aluminum plate that has been subjected to incomplete annealing after work hardening to reduce its strength to the specified index and reach level 2 hardness (not hard).

5754-H22 Aluminum is 5754 Aluminum in the H22 state. To achieve this temper, the metal needs to be strain hardened and then partially annealed, giving it about one-quarter the strength between annealed (O) and fully hard (H28).

5754 H22 aluminum plates can usually replace 5754 aluminum plates in other states, such as 5754 H32 aluminum.

- Process: work hardening, incomplete annealing

- Processing performance: 5754 H22 aluminum has excellent processing performance, weldability and easy processing and forming characteristics.

- Hardness status: Level 2 (not hard)

5754 H22 aluminum plate is widely used in: automotive industry: doors, molds, seals and other components. Other industries: such as railway passenger car interior and exterior wall panels, molds, seals, can manufacturing and other fields.

5754 aluminum is stronger than 5251. This high strength makes 5754 ideal for flooring applications. The performance standard for the mechanical properties of 5754 h22 is EN 485-2. If there are no special requirements, the H22 status of 5754 aluminum plate will usually replace other statuses, such as 5754 H32 aluminum plate.

5754 H22 aluminum plate is an aluminum-magnesium alloy containing 2.6%~3.6% magnesium, and its hardness is in the middle of the 5000 series. H22 is the tempering state of partially annealed aluminum plate with a hardness of 25%, and H32 is the tempering state of fully annealed aluminum plate with a hardness of 25%. Theoretically, the mechanical properties of h32 are more stable than h22, but the hardness is similar. Therefore, their application scope also overlaps.

Characteristics of 5754 h22 Aluminum

Through testing the mechanical properties of 5754 H22 under unwelded, primary welding, secondary welding and different tests of 5754 aluminum plates.

- Compared with unwelded 5754 H22 aluminum, the tensile strength of 5754 H22 aluminum that has been welded once is reduced by 7%-9%, the yield strength is reduced by 50%, and its elongation is increased by 11%-35%.

- The secondary welding tensile strength of 5754 H22 aluminum is reduced by 12%, the yield strength is reduced by 53%, and the elongation is increased by 8%.

Welding has little effect on the tensile strength of 5754 aluminum plate, but has a greater effect on its yield strength. Compared with primary welding, the mechanical properties of 5754 H22 aluminum do not decrease significantly after secondary welding.

Aluminum Plate 5754 H22 Specifications

Width/Length Range

The range of widths and lengths of 5754 H22 aluminum plates may vary depending on supplier and customer needs.

- Standard widths are usually between 1000mm (39.37in) and 1500mm (59.06in)

- Standard lengths range from 2000 mm (78.74 in) to 6000 mm (236.22 in).

Common Size

Aluminum sheet 5754 H22 is available in various sizes and custom sizes can also be obtained on specific request. Common sheet sizes are:

- 4 x 8 feet (1219mm x 2438mm)

- 4 x 10 feet (1219mm x 3048mm)

Common Thickness

Common thickness ranges for 5754 H22 aluminum plates are typically between 0.2 mm (0.008 in) and 6.35 mm (0.25 in), but other thicknesses are also available.

Mechanical properties of 5754 H22 aluminum plate

- Tensile strength (σb): 190~240 MPa

- Elongation: ≥12%

- Yield strength (σb): ≥80 MPa

- Implementation standard: EN 485-2

Aluminium 5754 h22 Properties

| Alloy | Temper | Specified Thickness (mm) | Rm (MPa) | Rp0.2 (MPa) | Elongation min.(%) | Bend radius a (90°) | Hardness (HBW a) |

| 5754 | H22/ H32 | 0.2-0.5 | 220-270 | 130 | 7 | 0, 5t | 63 |

| 5754 | H22/ H32 | 0.5-1.5 | 220-271 | 131 | 8 | 1, 0t | 64 |

| 5754 | H22/ H32 | 1.5-3.0 | 220-272 | 132 | 10 | 1, 5t | 65 |

| 5754 | H22/ H32 | 3.0-6.0 | 220-273 | 133 | 11 | 1, 5t | 66 |

| 5754 | H22/ H32 | 6.0-12.5 | 220-274 | 134 | 10 | 2, 5t | 67 |

| 5754 | H22/ H32 | 12.5-40.0 | 220-275 | 135 | 9 | 68 |

| Physical Property | Value |

| Density | 2.66 g/cm³ |

| Melting Point | 600 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 0.049 x10^-6 Ω .m |

| Mechanical Property | Value |

| Proof Stress | 130 Min MPa |

| Tensile Strength | 220 - 270 MPa |

| Hardness Brinell | 63 HB |

| Elongation A50 mm | 7 Min % |

Mechanical properties test of 5754 H22 aluminum plate

Comparison of mechanical properties between unwelded and welded

Unwelded 5754 H22 aluminum plate

As a baseline, unwelded 5754 H22 aluminum plate exhibits the original mechanical properties of the aluminum alloy.

5754 H22 aluminum plate after one welding

- Tensile strength: reduced by 7%-9%

- Yield strength: reduced by 50%

- Elongation: increased by 11%-35%

Conclusion: After welding once, the tensile strength is slightly reduced and the yield strength is significantly reduced, but the elongation is greatly increased.

5754 H22 aluminum plate after secondary welding

- Tensile strength: reduced by 12%

- Yield strength: reduced by 53%

- Elongation: increased by 8%

Conclusion: After secondary welding, the decrease in tensile strength and yield strength is slightly greater than that of primary welding, but the increase in elongation is slightly smaller.

- Tensile strength: Welding has little effect on the tensile strength of 5754 H22 aluminum plate. Although it has decreased after multiple weldings, the overall change is not significant.

- Yield strength: Welding has a great influence on the yield strength, especially it is significantly reduced after one welding.

- Elongation: Welding increases the elongation of the aluminum plate, and the increase in the number of welding times has little effect on it.

After welding, the mechanical properties of 5754 H22 aluminum plates have changed, but they still show good overall properties. In particular, its processing and welding properties make it an important material in the automotive and other industries. Although welding has a greater impact on yield strength, the changes in tensile strength and elongation are still within the acceptable range, ensuring its reliability and superiority in practical applications.

Al 5754 Chemical Composition

The chemical composition of a 5754 H22 aluminum plate usually includes the following elements:

- Element Composition (% by weight)

- Aluminum 97.3

- Magnesium 2.6

- Manganese 0.5

- Chromium 0.3

- Iron 0.4

- Silicon 0.25

- Copper 0.1

- Zinc 0.2

- 0.15 (each, maximum)

Please note that the specifications provided are approximate and may vary by supplier and specific production standards. It is always advisable to consult the supplier's technical data or industry standards for accurate and up-to-date information on the specification of Aluminum Sheet 5754 H22.

Aluminum 5754 h22 Typical Applications

5754 H22 Aluminum Sheet is a versatile material for a variety of applications where strength, corrosion resistance, and formability are critical.

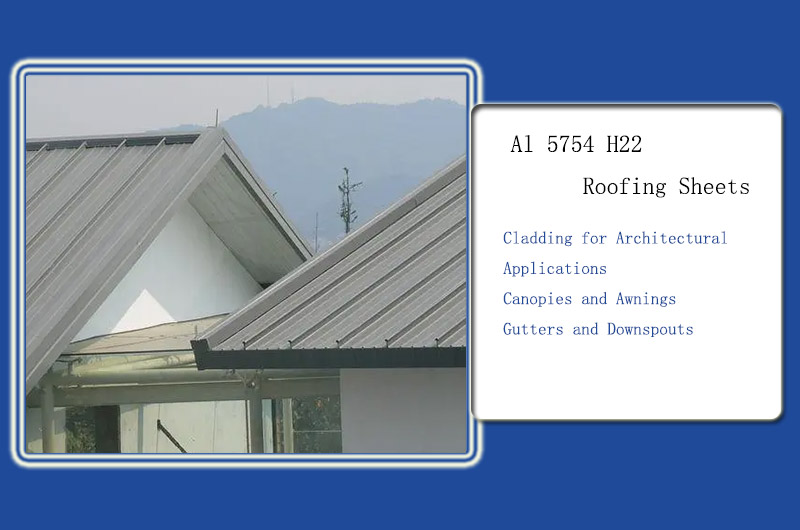

It is commonly used in the construction industry for roofing, siding, facades, and other structural components requiring strength and corrosion resistance.

5754 H22 Aluminum Sheet is also used in general sheet metal applications such as panels, housings, and automotive components.

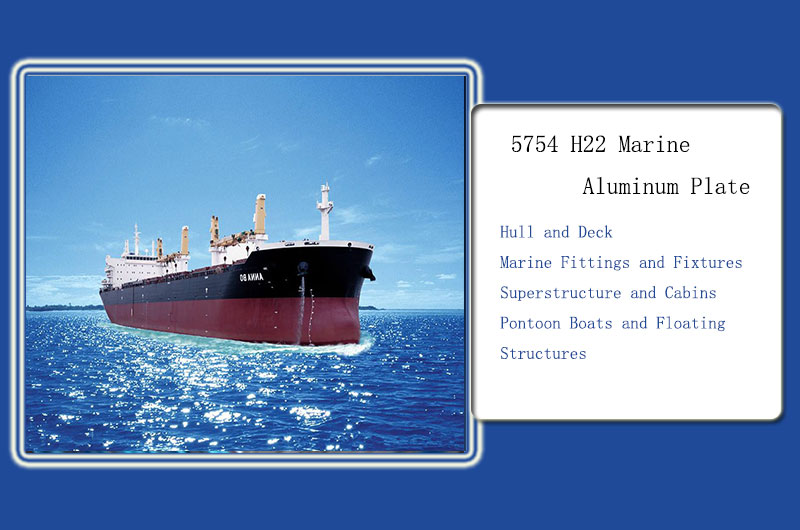

5754 H22 Marine Aluminum Plate

- hull and deck

- Marine Fittings and Fixtures

- superstructure and cabins

- Pontoon boats and floating structures

5754 h22 aluminum plate for fuel tanks

Able to withstand strong impacts without cracking or cracking

5754 H22 aluminum plate is used in fuel tanks because of its light weight, good tensile strength, and good corrosion resistance.

5754 H22 Automotive Aluminum Plates

- body panel

- Bumpers and Shock Structures

- Fuel tank and pipeline

- chassis components

- heat shield

5754 H22 aluminum has excellent processing properties. Its weldability and easy processing and shaping can well meet the processing requirements of the automotive industry. It is an ideal material for welding special-shaped automotive parts, such as door lines.

Al 5754 H22 Roofing Sheets

- Roof panels for residential, commercial, and industrial buildings

- Cladding for Architectural Applications

- Canopies and Awnings

- Gutters and Downspouts

5754 H22 Aluminum Plate for Truck and Trailer Bodies

- Truck and Trailer Body Panels

- Side panels and floors

- Cargo Containers and Compartments

- bulkhead

- Roof and Sidewall Protection

5754 H22 Railway Aluminum Plate

- Railway carriages and components

- Structural and Internal Panels

- floors and steps

- Handrails and Handrails

- overhead compartment

5754 H22 for Aerospace Aluminum Plate

- Aerospace structural parts

- aircraft fuselage panel

- wing and tail

- Interior fittings and partitions

- fuel tank and water tank

Note that these applications are only typical for 5754 H22, 5754 H22 aluminum can be used in a variety of other industries and applications where strength, corrosion resistance, and formability are an advantage.

-

5754 Automotive Aluminum Plate Sheet

5754 Automotive Aluminum Plate Sheet has good formability and can be easily formed into various automotive parts by rolling, bending, and stamping processes. It can be formed into complex shapes while maintaining its strength and integrity.

-

5754 Aluminum Plate for Tankers

5754 Aluminum Plate for Tankers Its light weight, corrosion resistance, durability and formability make it an ideal material for all types of tankers.

-

5754 marine aluminum plate is a deformed aluminum-magnesium alloy known for its excellent performance in the marine industry.

5754 h22 Aluminum Plate Sheet Available Sizes

| Product Thickness | length/Width(mm) |

| 0.5mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 0.8mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 0.8mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 1mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 1mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 1mm 5754 H22 Aluminum Sheet Plate | 3000x1250 |

| 1mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 1.2mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 1.2mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 1.5mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 1.5mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 1.5mm 5754 H22 Aluminum Sheet Plate | 3000x1250 |

| 1.5mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 1.5mm 5754 H22 Aluminum Sheet Plate | 4000x1500 |

| 2mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 2mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 2mm 5754 H22 Aluminum Sheet Plate | 3000x1250 |

| 2mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 2mm 5754 H22 Aluminum Sheet Plate | 4000x1500 |

| 2mm 5754 H22 Aluminum Sheet Plate | 4000x2000 |

| 2.5mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 2.5mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 2.5mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 3mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 3mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 3mm 5754 H22 Aluminum Sheet Plate | 3000x1250 |

| 3mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 3mm 5754 H22 Aluminum Sheet Plate | 4000x1500 |

| 4mm 5754 H22 Aluminum Sheet Plate | 2000x1000 |

| 4mm 5754 H22 Aluminum Sheet Plate | 2500x1250 |

| 4mm 5754 H22 Aluminum Sheet Plate | 3000x1500 |

| 4mm 5754 H22 Aluminum Sheet Plate | 4000x1500 |

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5754 h111 Aluminum Plate Sheet

5754 H111 aluminum plate is a rust-proof aluminum plate with good corrosion resistance. 5754 H111 aluminum has a wide range of uses and is mainly used in fields that require corrosion resistance such as ships and construction to improve the service life and safety of ships.

People also searched for Aluminum Plate

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5454 h32 Aluminum Plate Sheet

5454 h32 aluminum plate It has medium to high strength and excellent weldability, 5454 h32 has very good corrosion resistance, especially to seawater and general environmental conditions.

-

5454 h34 Aluminum Plate Sheet

5454-H34 Aluminum is 5454 aluminum in H34 condition. To achieve this temper, the metal needs to be strain hardened and then stabilized to a strength somewhere between annealed (O) and fully hard (H38).

-

5454 h111 Aluminum Plate Sheet

5454-H111 Aluminum is 5454 Aluminum in H111 condition. To achieve this temper, the metal is strain hardened below the strength allowed by H11 (1/8 hardness). 5454 H111 aluminum plate has good corrosion resistance and good formability.