5A06 Aluminum Plate Sheet

Temper: H112/O/T6 Competitive Prices

5A06 aluminum is a high-strength aluminum alloy that belongs to the 5xxx series of aluminum alloys. It is mainly composed of aluminum with a small amount of magnesium as the main alloying element. The "A06" in its name refers to the specific alloy composition.

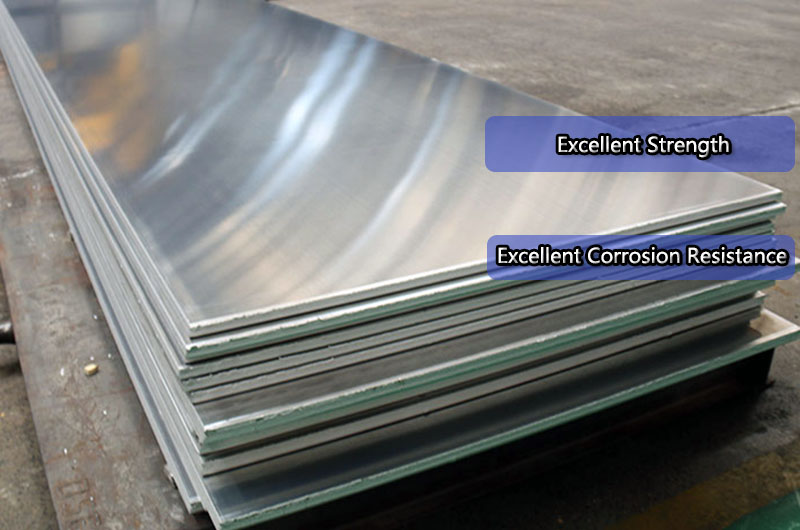

5A06 aluminum sheet/plate is an aluminum alloy with medium strength, excellent corrosion resistance, and good formability. It is commonly used in various applications requiring these properties.

5a06 Aluminum Alloy Characteristics

5A06 aluminum has excellent strength and corrosion resistance, making it suitable for a variety of applications in industries such as aerospace, transportation, and structural engineering. Some of its key features include:

- High in magnesium.

- It has good strength, corrosion resistance, and machinability in non-heat treatable alloys.

- The surface is beautiful after anodizing.

- Excellent welding performance, including arc welding.

When referring to 5A06 aluminum sheet or plate, it generally refers to a flat material of a specific size and thickness. These plates or panels are commonly used in structural applications, aerospace components, marine equipment, and other industries that require a combination of strength and corrosion resistance.

Specifications for 5A06 Aluminum Plates

Common gauges, dimensions, thicknesses, and tempering options for 5A06 aluminum plates may vary depending on specific requirements and manufacturing standards. However, the following are some common 5A06 aluminum sheet specifications:

| Specifications | Value |

|---|---|

| Alloy | 5A06 |

| Temper | O, H111, H112, H116, H321 |

| Thickness | 6 mm (0.24 in) - 200 mm (7.87 in) or more |

| Width | 1000 mm (39.37 in) - 2000 mm (78.74 in) or more |

| Length | 2000 mm (78.74 in), 2500 mm (98.43 in), 3000 mm (118.11 in), or custom lengths |

| Surface Treatment | Mill finish, brushed, anodized, or as per customer requirements |

| Standard | ASTM B209, EN573, EN485 etc |

| Equivalents of 5AO6 | UNS A95AO6, ISO AlMg6, Aluminium 5AO6, AA5AO6, Al5AO6 |

| Thickness (inches) | Thickness (mm) |

| 0.24" 5A06 Aluminum Plate | 6 |

| 0.31" 5A06 Aluminum Plate | 8 |

| 0.39" 5A06 Aluminum Plate | 10 |

| 0.47" 5A06 Aluminum Plate | 12 |

| 0.59" 5A06 Aluminum Plate | 15 |

| 0.79" 5A06 Aluminum Plate | 20 |

| 0.98" 5A06 Aluminum Plate | 25 |

| 1.18" 5A06 Aluminum Plate | 30 |

| 1.57" 5A06 Aluminum Plate | 40 |

| 1.97" 5A06 Aluminum Plate | 50 |

| 2.36" 5A06 Aluminum Plate | 60 |

| 2.76" 5A06 Aluminum Plate | 70 |

| 3.15" 5A06 Aluminum Plate | 80 |

| 3.94" 5A06 Aluminum Plate | 100 |

5A06 Aluminum Mechanical Properties

| Mechanical Property | Typical Value |

|---|---|

| Ultimate Tensile Strength | 250 - 320 MPa |

| Yield Strength σ0.2 (MPa) | ≥160 |

| Elongation | 10% - 16% |

| Modulus of Elasticity | 70 GPa (10, 000 ksi) |

5A06 Aluminum Alloy Physical Properties

| Property | Value |

|---|---|

| Density | 2.69 g/cm³ (0.097 lb/in³) |

| Melting Range | 525-640°C (977-1184°F) |

5A06 Aluminum Alloy Corrosion Resistance

5A06 aluminum sheet/sheet has excellent corrosion resistance, especially in marine and corrosive environments. Good resistance to the atmosphere, seawater, and industrial environment.

5A06 aluminum sheet/plate has good formability and can be easily formed into various shapes by bending, rolling, and other processing techniques.

It also has good machinability, enabling easy cutting, drilling, and milling operations.

Typical 5A06 Aluminum Plate

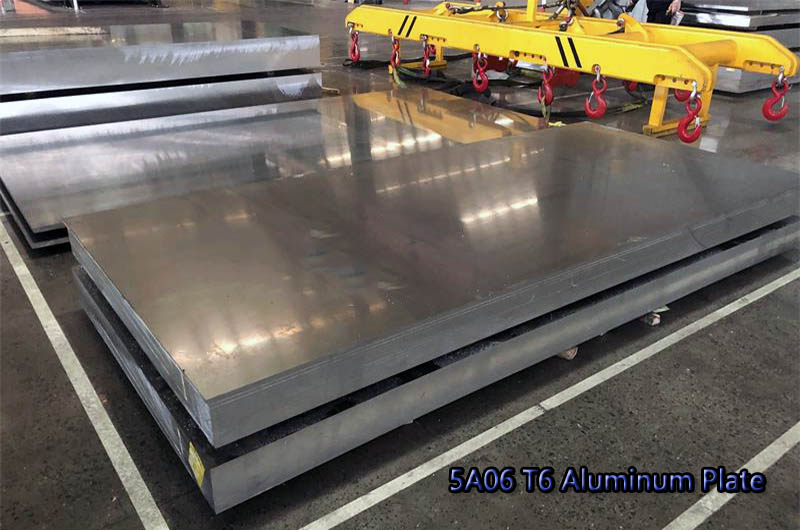

The most common temper for 5A06 aluminum plates is the T6 temper, which involves solution heat treatment and artificial aging for higher strength and hardness.

Other temper options available may include T4 (solution heat treated), O (annealed), and HXX tempers such as H111, H112, H116, and H321, depending on specific requirements.

5A06 H112 Aluminum Plate

- H112 is the temper designation for aluminum alloys. It refers to the strain hardened and partially annealed state. H112 tempering is achieved by heating the aluminum alloy to a specific temperature followed by rapid cooling followed by a natural or artificial aging process.

- Compared to the 5A06 H112 Aluminum annealed (O) temper, the H112 temper provides higher strength and hardness but may be less ductile.

- 5A06 H112 Aluminum Plate is typically used in applications requiring high strength, such as structural components in the aerospace, marine, and transportation industries.

5A06 O Aluminum Plate

- O stands for the annealed state, also known as the fully softened state. In this state, the aluminum sheet is at its greatest ductility and is easily shaped or formed.

- The 5A06O aluminum plate has not undergone any heat treatment except the annealing process.

- 5A06 H112 Aluminum is suitable for applications where formability and ease of fabrication are important but may have lower strength compared to tempered versions.

- Common uses for O-state aluminum include general sheet metal, cookware, signage, and decorative applications.

5A06 T6 Aluminum Plate

- T6 represents the state of solution heat treatment and artificial aging. It involves heating the aluminum alloy to a high temperature, then rapidly quenching it in water or other media, and then undergoing precipitation hardening.

- The T6 temper provides high strength and hardness while maintaining good formability.

- 5A06 T6 Aluminum is typically used in applications that require both strength and resistance to stress or corrosion, such as aerospace components, structural parts, and automotive frames.

Specific properties and applications of 5A06 aluminum alloy may vary depending on factors such as sheet thickness, fabrication techniques, and specific industry requirements. It is always recommended that you consult the manufacturer's specifications or engineering guides for accurate information on the alloy's properties and suitability for your intended application.

5A06 Aluminum Plate Typical Applications

- Due to its excellent corrosion resistance, it is widely used in offshore applications including ships.

- Used in automobiles, aircraft weldments, subway light rails, pressure vessels, etc. that require strict fire protection.

- Also found in refrigeration equipment, television towers, drilling equipment, transport equipment, missile parts, and armor.

5A06 aluminum plates are an excellent choice for a variety of applications when specific material properties meet project requirements. Here are some scenarios where 5A06 aluminum plates can be the best choice:

- Marine and Offshore Applications: 5A06 aluminum has excellent corrosion resistance, especially in saltwater environments, making it a first choice for marine and offshore applications. It is commonly used in ship hulls, ship superstructures, and offshore structures.

- Aerospace: In the aerospace industry, 5A06 aluminum is preferred for applications requiring a combination of strength, corrosion resistance, and formability. Can be used for aircraft structural parts.

- Transportation Industry: When a lightweight material with good corrosion resistance is required, 5A06 aluminum is suitable for a variety of transportation components. This includes auto parts, truck trailers, metro light rail, and transportation equipment.

- Pressure Vessels: 5A06 aluminum is used in the construction of pressure vessels and storage tanks that handle corrosive materials. Its corrosion resistance and moderate strength are advantageous in this regard.

- Construction: In construction, 5A06 aluminum is used in building elements, roofs, and siding, where resistance to environmental factors is critical.

- Welded structures: When welding is required, the good welding performance of 5A06 makes it a suitable choice for welded structures such as tanks, pipes, frames, etc.

- Offshore Oil and Gas: In the offshore oil & gas industry, 5A06 aluminum is used in a variety of components and structures that must withstand challenging marine environments.

- Missile Parts and Armor: The combination of strength and corrosion resistance makes it useful in military and defense applications, including missile parts and armor.

Choosing the 5A06 aluminum plate as the best choice depends on the specific requirements of the project, including factors such as corrosion resistance, strength, weight reduction, and formability. It is important to consider the properties of the alloy within the context of the application to make an informed decision.

Note: Specific properties and applications of 5A06 aluminum sheet/plate may vary depending on factors such as thickness, tempering, and specific manufacturing standards.

5a06 Aluminum Plate Heat Treatment Process

Heat treatment processes are a common method used to modify the properties of 5A06 aluminum alloy. Each of these heat treatment processes has a specific purpose and can be selected based on the desired material properties and application requirements:

1. 5a06 Aluminum Plate Homogenization Annealing

Purpose: To eliminate any chemical segregation or inhomogeneity in the alloy and improve its mechanical properties.

Process: Heat the material to 460 - 475℃, keep it for 12 - 14 hours, and then cool it in air.

2. 5a06 Aluminum Plate Rapid Annealing

Purpose: To soften materials and eliminate internal stress.

Procedure: Heat to 310 - 350°C, hold for 30 - 120 minutes, then cool with air or water.

3. 5a06 Aluminum Plate High Temperature Annealing

Purpose: to recrystallize the material and improve its ductility.

Procedure: Heat to 310 - 335°C, keep warm for a certain period of time, depending on the thickness of the finished product (≥6mm or less than 6mm), and then air cool.

4. 5a06 Aluminum Plate Low Temperature Annealing

Purpose: To further soften the material without affecting its previous heat treatment.

Procedure: Heat at 250 - 300°C or 150 - 180°C for the specified time of 12 hours or 23 hours respectively, then air cool.

Heat treatment can significantly affect the mechanical and thermal properties of aluminum alloys, allowing them to be customized to specific requirements. Properly applied heat treatment processes can improve the performance and durability of aluminum components in various industries including aerospace, automotive, and construction.

Factors Affecting the Price of 5a06 Aluminum Plate

The price of a 5A06 aluminum plate is affected by many factors. The following are some common factors:

- 1. Aluminum Market Price: Aluminum is a globally traded commodity, and its price will be affected by factors such as the balance of supply and demand in the international market, geopolitical factors, international trade policies, and currency exchange rate fluctuations. Therefore, global aluminum price trends have an important impact on the price of 5A06 aluminum plates.

- 2. Aluminum Plate Specifications and Dimensions: The price of a 5A06 aluminum plate is usually closely related to its specifications, size, and thickness. Generally speaking, larger or thicker aluminum panels will cost more due to the increased production process and material usage.

- 3. Market Demand: The demand for aluminum plates will affect the price. When market demand increases, prices may be increased. Conversely, if demand decreases, prices may fall.

- 4. Production and Supply: The cost of producing 5A06 aluminum plates depends on the production process, raw material costs, energy costs, and other factors. Production efficiency and capabilities also affect price.

- 5. Quality Requirements: High-quality, high-precision, or specially treated 5A06 aluminum plates may have a higher price because they require stricter production processes and quality control.

- 6. Market Region: Aluminum prices may vary in different regions, which partly depends on logistics costs, transportation distance and local market conditions.

- 7. Macroeconomic Factors: Macroeconomic factors, such as inflation rates, interest rates, and domestic, and international economic conditions, may have an impact on aluminum prices.

- 8. Government Policies and Tariffs: Trade policies, tariffs, and import restrictions may also have an impact on aluminum plate prices, especially policies targeting international trade.

- 9. Exchange Rate Fluctuation: Since aluminum is an international commodity, currency exchange rate fluctuations can have a direct impact on its price, especially in cross-border transactions.

Aluminum prices are a complex combination of factors and may vary at different times and locations. If you are concerned about the price when purchasing 5A06 aluminum plates, it is recommended to communicate more with suppliers and consider the above factors to make an informed decision.

High-quality 5A06 Aluminum Plate Supplier - Haomei Aluminum

- Quality Standards: With certifications such as ISO 9001, consistent quality is maintained throughout the manufacturing process.

- Material certification: provide the material certification or test report of its 5A06 aluminum plate. These documents confirm that the material meets the required specifications and standards.

- Product Range: Available in various 5A06 Aluminum Sheet sizes, thicknesses, and dimensions. Have a variety of product series to meet different application requirements and provide flexibility for your choice.

- Technical Support: Provides technical assistance and guidance that can answer your questions about product specifications, applications, and any other issues you may be concerned about.

People also searched for Aluminum Plate

-

5182 Aluminum Plate Sheet

5182 aluminum plate, which is a deformed alloy with good corrosion resistance, good weldability, corrosion resistance, medium strength and cold working properties.

-

5454 Aluminum Plate Sheet

The strength of 5454 antirust aluminum is about 20% higher than that of 5052, and its characteristics are roughly the same as that of 5154, but its corrosion resistance is better than that of 5154 in severe environments.

-

5754 Aluminum Plate Sheet

The strength of 5754 aluminum is higher than that of 5251. 5754 aluminum plate is a high-strength non-heat-treatable alloy and has excellent corrosion resistance, good processability, and weldability.

-

5086 Aluminum Plate Sheet

5086 aluminum is not strengthened by heat treatment, but rather becomes stronger by strain hardening or cold machining of the material. 5086 aluminum sheet is commonly used in marine, cryogenic, pipeline, military, chemical and gas/oil/petroleum applications.

-

5005 Aluminum Plate Sheet

5005 aluminum is a medium-strength aluminum alloy with a small amount of magnesium as the main alloying element. It has good formability and is often used in applications requiring anodized surface treatments.

-

5052 Aluminum Plate Sheet

5052 aluminum plate is mainly composed of magnesium and chromium. It has good processability, medium static strength, high fatigue strength, and good weldability. The fatigue strength of 5052 aluminum alloy is higher than most aluminum alloys.

-

5083 Aluminum Plate Sheet

5083 aluminum plate is a non-heat treatable alloy with high strength and corrosion resistance. We offer a wide range of sizes, thicknesses, and specifications at affordable prices to meet customer-specific needs.