6063 Aluminum Plate Sheet

Temper: T6/T5/T4/T3 Complete Specifications

What is 6063 Aluminum?

As a typical extrusion alloy, 6063 aluminum alloy’s profile products are widely used in various fields.

6063 aluminum alloy is one of the 6 series aluminum alloys. It is widely used in building doors, windows, curtain wall frames, etc. due to its unique welding performance, good plasticity, and gorgeous color after anodization.

6063 aluminum alloy is a reinforced alloy in the Al, Mg, Si series with moderate strength and can be heat treated. The alloy uses aluminum as the matrix, supplemented by magnesium, silicon, iron, copper, manganese, zinc and other elements.

6063 is the most commonly used alloy for aluminum extrusion and is not as strong as 6061 and 6082. 6063 is commonly known as a construction alloy because it is suitable for anodizing and has a smooth surface for easy forming, so it is popular in visible architectural applications such as window frames, door frames, and Roof And Flag frames.

In order to ensure that doors, windows, and curtain walls have high wind pressure resistance, assembly performance, corrosion resistance, and decorative performance, the comprehensive performance requirements for aluminum alloy profiles are much higher than industrial profile standards.

AA 6063 generally has good mechanical properties, is heat treatable, weldable, can be formed into complex shapes, and has a very smooth surface suitable for anodizing, making it popular in visible architectural applications such as window frames, door frames, roofs, and sign frames.

Standard Specification for Aluminium 6063 Plate

- Specification: ASTM B209 / ASME SB209

- Thickness: 0.2~300mm

- Width: 500~2500mm

- Length: 500~10000mm

- Finish: Mill, Customer specific finish

- Type: HR / CR Sheet / Strips/ Coils/ Chequered Plates

6063 Aluminum Properties

Here are some key features and specifications of the 6063 aluminum plate:

- Strength: 6063 aluminum has moderate strength characteristics and is suitable for occasions where strength requirements are not extremely high.

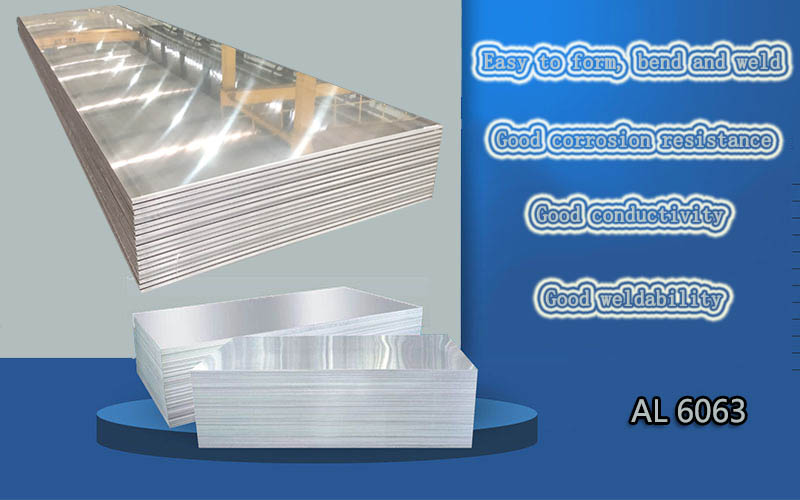

- Processability: It has excellent processability and is easy to form, bend, and weld. It can be extruded into complex shapes and profiles, which is why it is often used in architectural applications.

- Corrosion resistance: 6063 aluminum has good corrosion resistance, especially in atmospheric conditions. However, it is not recommended for applications exposed to salt water or highly corrosive environments.

- Surface Finish: The alloy provides a smooth and aesthetic finish, making it popular for architectural applications such as window frames, door frames, and curtain walls.

- Conductivity: 6063 aluminum has good conductivity and is suitable for electronic applications and heat sinks.

- Heat treatment: 6063 aluminum can be heat treated to improve its mechanical properties such as strength and hardness. The most common heat treatment for this alloy is T6, which includes solution heat treatment and artificial aging.

- Weldability: 6063 aluminum is generally considered to have good weldability, forming strong and reliable joints.

Types Of Aluminium 6063 Plate

| Aluminium Alloy UNS A96063 Plate | Aluminium 6063 Tread Plates Stockists |

| Aluminium 6063 Circle Trader | 6063 Aluminium CR Sheets |

| Aluminium 6063 Blank Dealer | Aluminium 6063 Ring Distributor |

| Aluminium 6063 Foil Manufacturers | 6063 Aluminium Strip Stockholder |

| Aluminium 6063 Hot Forming Plate | Aluminium Werkstoff-Nr. 3.32206 Plate |

| ASTM B209 Aluminium A96063 Plate Supplier | Commercial Aluminium 6063 Plate |

| ASME SB209 Aluminium 6063 Plate | 6063 Aluminium Checkered Plate |

| Aluminium 6063 Hot-Rolled (HR) Plate | Aluminium 6063 Cold-Rolled (CR) Sheet |

Aluminium 6063 Sheet and Plates Equivalent Grades

| UNS | A96063 | |

| WNR | 3.32206 | |

| DIN | AlMgSi0.5 | |

| EN | AW-AlMg0, 7Si | EN AW-6063 |

| ISO | AlMg0, 7Si | |

| BS (OLD) | HE9 | |

| USA | AA6063 | |

6063 Aluminum Data Sheet

6063 Aluminum Alloy Plate Specifications

| Properties | Value |

|---|---|

| Material temper | T3, T4, T5, T6 etc. |

| Thickness | 0.2-500 mm |

| Width | 100-2650 mm |

| Length | Customize |

| Alloy Types | Sheet, Coil, Plate, Tread plate, etc. |

Condition: The most commonly used condition for the 6063 aluminum plate is T6, which provides good mechanical properties and strength.

6063 Aluminum Typical Temper

The mechanical properties of 6063 depend largely on the tempering or heat treatment of the material.

- 6063-O

- 6063-T1

- 6063-T4

- 6063-T5

- 6063-T6

- 6063-T52

- 6063-T53

- 6063-T54

- 6063-T55

- 6063-T832

6063 Aluminum Mechanical Properties (Typical Values)

| Properties | Value |

|---|---|

| Young's modulus (E) | 68.3 GPa (9, 910 ksi) |

| Tensile strength (σt) | 145–186 MPa (21.0–27.0 ksi) |

| Yield Strength | 55-145 MPa |

| Hardness (Brinell) | 45-95 HB |

| Elongation (ε) at break | 18–33% |

| Poisson's ratio (ν) | 0.3 |

Physical Properties 6063 Aluminum Plate Sheet

| 6063 | -T52 | -T6 |

| Density | 0.098 lb/in3 | 0.098 lb/in3 |

| Ultimate Tensile Strength | 27 ksi | 35 ksi |

| Yield Tensile Strength | 21 ksi | 31 ksi |

| Fatigue Strength | 9.7 ksi | 10 ksi |

| Shear Strength | 15 ksi | 22 ksi |

| Shear Modulus | 3, 700 ksi | 3, 770 ksi |

| Hardness Rockwell | Brinell | B17 | 60 | B27 | 65 |

| Elongation at Break Percentage | 12% | 22% |

| Modulus of Elasticity | 10, 000 ksi | 10, 000 ksi |

| Poisson's Ratio | 0.33 | 0.33 |

| Machinability Percentage | N/A | 50% |

| Melting Point | 1, 140-1, 210 °F | 1, 140-1, 210 °F |

| Specific Heat | 2.15 x 10^-1 BTU/lb-°F | 2.15 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 1, 450 BTU-in/hr-ft^2-°F | 1, 390 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 53% IACS | 53% IACS |

6063 Aluminum Chemical Composition (Typical Values)

| Element | Composition Range (%) |

|---|---|

| Silicon | 0.20-0.60 |

| Iron | 0.0-0.35 |

| Copper | 0.0-0.10 |

| Manganese | 0.0-0.10 |

| Magnesium | 0.45-0.90 |

| Chromium | 0.0-0.10 |

| Zinc | 0.0-0.10 |

| Titanium | 0.0-0.10 |

| Aluminum | Remainder |

6063 Aluminum Plate Accreditations

- ISO9001

- AS9100

- OHSAS 18001

- ISO14001

- NADCAP HT

- NADCAP NDT

- IATP16949

Typical 6063 Aluminum Plate

6063-T6, 6063-T5, 6063-T4, and 6063-T3 refer to different tempers or states of 6063 aluminum alloy. The temper designation indicates the mechanical properties obtained by heat treatment and is represented by a combination of letters and numbers. Here is a brief description of each temper:

-

6063 T6 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the 6063 T6 aluminum plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Able to meet the requirements of different customers, including customized sizes and specifications.

-

6063 T5 Aluminum Plate Sheet

6063 T5 Aluminum Plate Sheet suppliers should offer competitive prices without compromising product quality.

-

6063 T4 Aluminum Plate Sheet

6063-T4 aluminum has good formability and is suitable for various manufacturing processes such as bending, forming, and extrusion.

6063-t6 Aluminum Plate

T6 is the most common temper of 6063 aluminum, this temper has excellent mechanical properties.

- 6063 T6 indicates that the aluminum has been solution heat treated and artificially aged for maximum strength and hardness.

- 6063-t6 Aluminum Sheet is commonly used in applications requiring significant strength, such as structural components, frames, and aerospace applications.

6063-t5 Aluminum Plate

T5 is another common temper of 6063 aluminum, the T5 temper provides good strength.

- 6063 T5 indicates that the aluminum has been artificially aged after cooling during high-temperature forming.

- 6063-t5 Aluminum Sheet is widely used in architectural and decorative applications such as window frames, door frames, and extruded profiles.

6063-t4 Aluminum Plate

The T4 temper is achieved by solution heat treatment and natural aging.

- It offers lower strength but improved formability and machinability compared to T6 and T5 tempers.

- 6063-T4 aluminum is typically used in applications where formability and ease of fabrication are more important than high strength.

6063-t3 Aluminum Plate

T3 temper is achieved by solution heat treatment and cold working.

- 6063 T3 It provides moderate strength and good formability.

- 6063-T3 aluminum is typically used in applications requiring moderate strength and excellent formability, such as building components, tubing, and furniture.

Aluminium 6063 Plate Processing

- Hot rolled

- Cold rolled

- Cutting

- Forming Drilling/ Machining

- Grinding

- Polishing

- Testing

6063 aluminum sheet stock list

| Product | Width(inch) | Length(inch) |

| 0.008" Aluminum Sheet 6063-T651 | 12" | 12" |

| 0.01" Aluminum Sheet 6063-T651 | 12" | 24" |

| 0.012" Aluminum Sheet 6063-T651 | 12" | 36" |

| 0.013" Aluminum Sheet 6063-T651 | 12" | 48" |

| 0.014" Aluminum Sheet 6063-T651 | 24" | 24" |

| 0.016" Aluminum Sheet 6063-T651 | 24" | 36" |

| 0.018" Aluminum Sheet 6063-T651 | 24" | 48" |

| 0.02" Aluminum Sheet 6063-T651 | 36" | 36" |

| 0.024" Aluminum Sheet 6063-T651 | 36" | 48" |

| 0.031" Aluminum Sheet 6063-T651 | 48" | 48" |

| 0.039" Aluminum Sheet 6063-T651 | 48" | 144" |

| 0.047" Aluminum Sheet 6063-T651 | 12" | 12" |

| 0.059" Aluminum Sheet 6063-T651 | 12" | 24" |

| 0.063" Aluminum Sheet 6063-T651 | 12" | 36" |

| 0.071" Aluminum Sheet 6063-T651 | 12" | 48" |

| 0.079" Aluminum Sheet 6063-T651 | 24" | 24" |

| 0.098" Aluminum Sheet 6063-T651 | 24" | 36" |

| 0.118" Aluminum Sheet 6063-T651 | 24" | 48" |

| 0.157" Aluminum Sheet 6063-T651 | 36" | 36" |

| 0.197" Aluminum Sheet 6063-T651 | 36" | 48" |

| 0.236" Aluminum Sheet 6063-T651 | 48" | 48" |

| 0.008" Aluminum Sheet 6063-T5 | 48" | 144" |

| 0.01" Aluminum Sheet 6063-T5 | 12" | 12" |

| 0.012" Aluminum Sheet 6063-T5 | 12" | 24" |

| 0.013" Aluminum Sheet 6063-T5 | 12" | 36" |

| 0.014" Aluminum Sheet 6063-T5 | 12" | 48" |

| 0.016" Aluminum Sheet 6063-T5 | 24" | 24" |

| 0.018" Aluminum Sheet 6063-T5 | 24" | 36" |

| 0.02" Aluminum Sheet 6063-T5 | 24" | 48" |

| 0.024" Aluminum Sheet 6063-T5 | 36" | 36" |

| 0.031" Aluminum Sheet 6063-T5 | 36" | 48" |

| 0.039" Aluminum Sheet 6063-T5 | 48" | 48" |

| 0.047" Aluminum Sheet 6063-T5 | 48" | 144" |

| 0.059" Aluminum Sheet 6063-T5 | 12" | 12" |

| 0.063" Aluminum Sheet 6063-T5 | 12" | 24" |

| 0.071" Aluminum Sheet 6063-T5 | 12" | 36" |

| 0.079" Aluminum Sheet 6063-T5 | 12" | 48" |

| 0.098" Aluminum Sheet 6063-T5 | 24" | 24" |

| 0.118" Aluminum Sheet 6063-T5 | 24" | 36" |

| 0.157" Aluminum Sheet 6063-T5 | 24" | 48" |

| 0.197" Aluminum Sheet 6063-T5 | 36" | 36" |

| 0.236" Aluminum Sheet 6063-T5 | 36" | 48" |

| 0.008" Aluminum Sheet 6063-T6 | 48" | 48" |

| 0.01" Aluminum Sheet 6063-T6 | 48" | 144" |

| 0.012" Aluminum Sheet 6063-T6 | 12" | 12" |

| 0.013" Aluminum Sheet 6063-T6 | 12" | 24" |

| 0.014" Aluminum Sheet 6063-T6 | 12" | 36" |

| 0.016" Aluminum Sheet 6063-T6 | 12" | 48" |

| 0.018" Aluminum Sheet 6063-T6 | 24" | 24" |

| 0.02" Aluminum Sheet 6063-T6 | 24" | 36" |

| 0.024" Aluminum Sheet 6063-T6 | 24" | 48" |

| 0.031" Aluminum Sheet 6063-T6 | 36" | 36" |

| 0.039" Aluminum Sheet 6063-T6 | 36" | 48" |

| 0.047" Aluminum Sheet 6063-T6 | 48" | 48" |

| 0.059" Aluminum Sheet 6063-T6 | 48" | 144" |

| 0.063" Aluminum Sheet 6063-T6 | 12" | 12" |

| 0.071" Aluminum Sheet 6063-T6 | 12" | 24" |

| 0.079" Aluminum Sheet 6063-T6 | 12" | 36" |

| 0.098" Aluminum Sheet 6063-T6 | 12" | 48" |

| 0.118" Aluminum Sheet 6063-T6 | 24" | 24" |

| 0.157" Aluminum Sheet 6063-T6 | 24" | 36" |

| 0.197" Aluminum Sheet 6063-T6 | 24" | 48" |

| 0.236" Aluminum Sheet 6063-T6 | 36" | 36" |

What is 6063 Aluminum Used for?

6063 aluminum is commonly used in various applications due to its excellent strength, corrosion resistance, and machinability. 6063 aluminum plate is widely used in construction, automobile, electronics, and other industries. 6063 is mainly used in construction manufacturing, door and window frames, pipes, and aluminum furniture.

1. 6063 Aluminum Plate for Motor Housing

6063 aluminum alloy motor shell is light in weight, has good heat dissipation performance, good thermal conductivity, easy to process, good plasticity, high elongation, good shape, high cleanliness, energy saving, and environmental protection, and can be reused It has high utilization value and is a new green and environmentally friendly product.

2. 6063 Aluminum Plate for Electric Fuel Pump

The processable thickness range of 6063 aluminum plate is: 0.3-600mm, and the width is: 500-2650mm. The main material states are F, O, H112, T4, T6, T651. It is often used in electric fuel pumps. Currently, 6063 aluminum plates are used in electric fuel pumps. The performance is relatively stable and reliable.

3. 6063 Aluminum Plate for Computer Chassis

Commonly used materials for computer cases include galvanized sheets, cold-rolled sheets, aluminum sheets, etc. At present, 6063 aluminum sheets are a more common case material due to their better thermal conductivity and faster heat dissipation.

4. 6063 Aluminum Alloy Plate for Radiator

The shovel tooth radiator is a relatively popular type of radiator. It uses shoveling technology to cut a whole piece of metal into a set of regular teeth. The cut heat dissipation teeth are thin and dense, and can Achieving ultra-thin teeth and spacing, and ultra-high magnification main structure effectively increases the heat dissipation area.

High-power radiators generally use 6063 aluminum plates as the base plate, with a thickness of 1-30mm. Through mechanical action, the material is cut into sheets at a certain angle and straightened. Repeated cutting forms a uniform gap structure, which is used under air-cooled heat dissipation conditions. To solve the problem of heat dissipation of high-power devices, it can improve the heat dissipation efficiency by 8-15% compared with insert radiators. It is widely used in large heat dissipation devices such as photovoltaic inverters, wind power converters, electric vehicle controllers, and power battery packs.

5. 6063 Aluminum Plate for Automobiles

6063 aluminum plate is mainly used to make the overall outline of the car body and the body of the tank truck. The 6063 aluminum car body has the advantages of being light, heat-resistant, good in printing, recyclable, and reducing vehicle fuel consumption.

6. 6063 Mold Aluminum Plate

6063 aluminum plate is a typical aluminum for die-casting molds and is widely used in various mold manufacturing. The main alloying elements of the 6063 aluminum plate are magnesium and silicon. It has good processing performance, excellent weldability, extrusion and electroplating properties, good corrosion resistance, toughness, easy polishing, coating, and excellent anodizing effect.

7. 6063 Aluminum Plate for Precision Machinery

6063 aluminum plate is widely used in precision machinery and automobiles due to its good corrosion resistance, and ease of polishing and processing. The 6063 aluminum plate is filmed on both sides and has a flat shape, which has been praised by many customers.

8. 6063 Aluminum for Bicycle Wheels

Initially, 6063 aluminum was used to manufacture individual non-stressed parts of bicycles, and now all-aluminum bicycles have been developed. 6063 aluminum is used for bicycle wheels. The aluminum rim is light and has a small moment of inertia, so acceleration and deceleration are more labor-saving. There are many steel rims for vehicles with medium and low speeds, large diameters, impact, and heavy loads.

9. 6063 Aluminum Alloy for Rolling Shutter Door Material

Compared with ordinary rolling shutter doors, rolling shutter doors made of 6063 aluminum alloy have considerable advantages in terms of appearance, environmental protection, and safety. The 6063 aluminum alloy rolling shutter door can be sprayed with various colors and patterns on its surface, and can also be coated with concave and convex wood grains, sand grains, etc. to highlight its noble temperament, significantly improve the grade of your shop, and make you stand out among many shops.

It is worth noting that while 6063 aluminum offers many advantages, specific application requirements, environmental conditions, and design considerations should be considered when selecting the appropriate aluminum alloy.

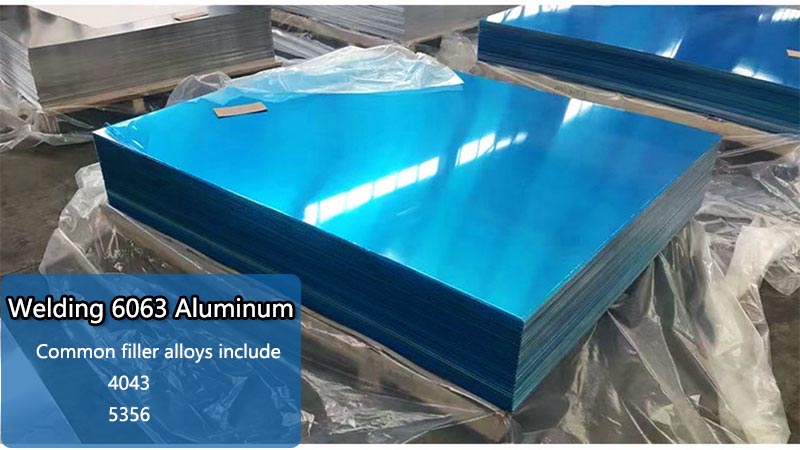

Welding 6063 Aluminum

6063 is highly weldable and after welding, the properties near the weld are the same as 6063-0 with up to 30% strength loss. The material can be reheat-treated to return the entire part to a higher temperature.

Welding 6063 aluminum can be accomplished using a variety of welding methods. However, due to its alloy composition and properties, there are a few considerations that should be kept in mind for successful welding.

- Aluminum welding processes: Common welding processes for aluminum, including 6063, are tungsten inert gas (TIG) welding and metal inert gas (MIG) welding. TIG welding is often favored for its precise control and high-quality welds, while MIG welding can weld thicker sections faster and more efficiently.

- Cleanliness: Proper cleaning of aluminum surfaces prior to welding is critical. Aluminum can form an oxide layer that prevents proper soldering. Use stainless steel brushes or appropriate cleaning methods to remove scale, oil, grease, or any other contaminants.

- Filler Material: Use an aluminum alloy filler wire that matches or is compatible with 6063 aluminum. Common filler alloys include 4043 and 5356.

- Shielding gas: Argon is commonly used as a shielding gas in aluminum welding. It helps protect the weld pool from atmospheric contamination and provides good arc stability. Depending on the welding method and application requirements, pure argon or a mixture of argon and helium can be used.

- Welding parameters: Welding parameters such as current, voltage, travel speed, and heat input should be properly adjusted according to the thickness of the aluminum and the desired weld quality. It is important to maintain a stable arc and control the heat input to avoid distortion and ensure proper fusion.

- Preheating and post-weld heat treatment: Welding 6063 aluminum generally does not require preheating. However, for thicker sections or critical applications, preheating may be recommended. 6063 aluminum generally does not require post-weld heat treatment.

- Joint Design and Fitting: Proper joint design, fit and edge preparation are critical to successful welding. Beveling the edges or using a V-groove joint configuration can improve penetration, and weld quality. Proper fit and alignment ensure good solder fusion.

- Welding Technique and Speed: Use a consistent and controlled welding technique with steady movement along the joint to achieve uniform penetration and weld appearance. Avoid excessive heat buildup by controlling the welding speed and adjusting the travel speed accordingly.

- Post-solder cleaning and inspection: After soldering, clean the soldering area to remove any residual flux or spatter. Inspect welds for defects such as cracks, lack of fusion, or porosity. Nondestructive testing methods, such as visual inspection, dye penetrant testing, or radiographic testing, can be used for quality assurance.

6063 Aluminum Processing Precautions

Controlling the composition of 6063 aluminum alloy profiles is essential to ensure that the material meets the desired performance standards and achieves the required mechanical properties while maintaining extrudability and surface quality.

1. Control of Mg2Si Content: The amount of Mg2Si, which is a key strengthening phase in 6063 aluminum alloy, is typically controlled within the range of 0.75% to 0.80%. This control ensures that the alloy meets the required mechanical properties while retaining good extrudability and other desirable characteristics.

2. Tensile Strength: When the Mg2Si content is maintained within the specified range and under normal extrusion conditions (with a coefficient greater than or equal to 30), the tensile strength of the extruded profile falls within the range of 200 to 240 MPa. This range is commonly observed and expected for 6063 alloys.

3. Benefits of Controlled Alloying: Controlling the alloy composition in this manner offers several advantages, including good plasticity (ease of extrusion), high corrosion resistance, and excellent surface treatment performance. Additionally, this approach can help optimize alloy usage, which is cost-effective.

4. Strict Control of Impurity Fe: Maintaining low levels of iron (Fe) impurities is crucial. High Fe content can lead to various issues, including increased extrusion force, reduced surface quality of extruded material, dark or dull anodization colors, and decreased plasticity and corrosion resistance. Therefore, it's advisable to control Fe content within the range of 0.15% to 0.25% to avoid these problems.

Proper alloy control and quality management are critical factors in the production of high-quality aluminum extrusions for various applications.

6063 Aluminum Surface Corrosion Phenomenon

These practices and considerations are crucial for maintaining the quality and appearance of 6063 aluminum alloy profiles, especially when silicon-related corrosion is a concern. Proper alloy control, process management, and surface treatment can help ensure that the profiles meet usage requirements and exhibit the desired corrosion resistance and aesthetics.

1. Prevention Through Alloy Control

- The prevention of corrosion caused by silicon starts with effective control of raw materials and alloy composition.

- Maintain the ratio of magnesium to silicon within the range of 1.3 to 1.7 to ensure the formation of a beneficial Mg2Si strengthening phase.

- Strictly control the parameters of each manufacturing process to avoid silicon segregation and dissociation.

2. Surface Treatment Considerations

- If silicon corrosion spots are observed on the surface, specific surface treatment techniques can be employed.

- During the degreasing and degreasing process, consider using a weak alkaline bath. If not possible, extend the soaking time in an acidic degreasing solution.

- Control the pH value of the washing water to be higher than pH 4 and minimize the chloride ion (Cl-) content.

- During the alkali corrosion process, extend the corrosion time as much as possible.

- Utilize a nitric acid brightening solution for neutralization after alkali corrosion.

- Promptly perform sulfuric acid anodization to oxidize and seal the surface, reducing the visibility of dark gray corrosion spots caused by silicon.

Which is better 6061 or 6063?

6063 Aluminum vs. 6061

- Strength: Compared with 6063 aluminum, 6061 aluminum has higher tensile strength and yield strength. It is generally considered stronger and better suited for applications requiring greater structural strength.

- Machinability: Both alloys have good machinability, but 6061 aluminum is generally easier to machine due to its higher hardness.

- Extrudability: 6063 aluminum has excellent extrudability, making it ideal for manufacturing complex shapes and profiles. It is often the first choice for architectural and decorative applications.

- Corrosion Resistance: Both alloys have good corrosion resistance, especially under normal atmospheric conditions. However, 6063 aluminum may have slightly better corrosion resistance due to its higher silicon content.

- Weldability: Both alloys have good weldability and can be welded easily using a variety of methods.

Typical Application

- 6061 aluminum is commonly used in structural components, frames, aerospace applications, automotive components, and heavy structures where strength is a major requirement.

- 6063 aluminum is commonly used in architectural applications, extruded profiles, furniture, electrical enclosures, radiators, and plumbing.

- If strength is a top priority and the application requires greater structural integrity, 6061 aluminum is often preferred.

- However, if extrudability, aesthetics, and corrosion resistance are more important, 6063 aluminum is usually chosen.

The specific requirements of your application must be considered to determine which alloy is better suited to your needs.

People Also Searched for 6063 Aluminum

aluminium plate grade 6063, aluminium alloy 6063 equivalent, aluminium 6063 plate suppliers, checker plate aluminium 6063, aluminium 6063 plate supplier, aluminium alloy 3.32206 plate, aluminium gr 6063 plate stockholder, aluminium alloy 6063 specification, aluminum 6063 roofing sheet and plate, aluminium 6063 plate traders, aluminium 6063 plate stockists, 6063 aluminum plate suppliers, aluminium 6063 plates manufacturer, aluminium 6063 plate stockholder, 6063 aluminum tread plate, aluminium 6063 plates, aluminium 6063 flat sheets, aluminium 6063 plate manufacturers, aluminium 6063 plate price, aluminium 6063 bright plates, aluminum alloy grade 6063 plates, pvc coated aluminium 6063 plate, aluminium 6063 plate thickness, aluminium plate 6063, color coated aluminium 6063 plates, aluminium 6063 chemical properties, 6063 aluminium plate cut to size, aluminium 6063 plate size, aluminium 6063 mechanical properties, 6063 aluminum machinability, aluminium 6063 plate stockists, aluminium 6063 patterned plate and sheet, aluminium 6063 plate exporter, aluminium 6063 plate exporters, aluminium alloy plate 6063, 6063 plate aluminum properties, aluminium 6063 plates dealer.

Frequent questions about 6063 aluminum plate?

What are the main characteristics of 6063 aluminum plate?

6063 aluminum plate has good squeezing performance, corrosion resistance and surface smoothness. They are also known for medium -intensity and excellent thermal conductivity.

Is 6063 aluminum plate suitable for welding?

Yes, 6063 aluminum can be welded in multiple methods, including tig and mig welding. However, the post -welding timeliness may be required to restore the intensity of the thermal influence zone.

What is the typical thickness range of 6063 aluminum plate?

The 6063 aluminum plate has a variety of thickness, usually from several millimeters to a few inches, depending on the specific purpose.

People also searched for Aluminum Plate

-

6082 Aluminum Plate Sheet

6082 aluminum plate is known as the strongest alloy among the 6000 series alloys. 6082 aluminum is lightweight, easy to form, and can be strengthened through heat treatment.

-

6082 T6 Aluminum Plate Sheet

6082 T6 Aluminum Plate Sheet has stable performance and complete specifications and can be customized according to customer needs.

-

6082 T651 Aluminum Plate Sheet

We strictly control the quality of the 6082 T651 Aluminum Plate Sheet, ensuring that each sheet meets the highest industry standards, stable performance, and competitive price.

-

6082 T4 Aluminum Plate Sheet

6082 T4 Aluminum Plate Sheet has strict quality control measures throughout the manufacturing process to ensure consistent quality