6063 T4 Aluminum Plate Sheet

Strict Quality Control Stable Performance

What is 6063 T4 Aluminum?

6063 T4 aluminum plate refers to a specific type of aluminum plate made from 6063 alloy, a medium-strength alloy commonly used in construction applications, automotive parts, and other structural components.

In the T4 state, 6063 aluminum has been solution heat treated and naturally aged to a basically stable state. This temper provides good formability and machinability while retaining some of the alloy's strength properties. It is often selected for applications where forming or bending is required but high strength is not important.

6063 T4 aluminum plate generally has good corrosion resistance, excellent weldability and good machinability. It is typically used in extruded shapes such as beams, channels, and tubes, but plates can also be used in applications that require a flat surface.

UNS A96063; ISO AlMg0.5Si; Aluminium 6063-T4; AA6063-T4; Al6063-T4;

6063 T4 aluminum is a special temper in the 6063 aluminum alloy family. The "T4" designation indicates the tempering treatment the aluminum has undergone. Here's what it means:

6063 T4 Aluminum:

- T4 tempering includes solution heat treatment and natural aging.

- Solution heat treatment involves heating an aluminum alloy to a specific temperature followed by rapid quenching to achieve a solid solution of alloying elements.

- Natural aging refers to the aging process that occurs over time at room temperature.

- The T4 temper offers improved formability and machinability compared to the annealed (O) condition, but reduced strength compared to other temper designations.

6063-t4 Aluminum Plate Properties

- Corrosion Resistance: 6063-T4 aluminum has good corrosion resistance and is suitable for outdoor and architectural applications. However, it is less corrosion-resistant than some other aluminum alloys such as 6061-T6.

- Formability: 6063-T4 aluminum has good formability and is suitable for various manufacturing processes such as bending, forming, and extrusion.

Advantages and disadvantages of 6063 t4 aluminum plate

Advantages

- LIGHTWEIGHT: Aluminum is lightweight, making it suitable for applications where weight reduction is required.

- Recyclability: Aluminum is highly recyclable, contributing to sustainability and environmental protection.

- Aesthetics: Its smooth surface finish and ability to be coated or anodized provides designers with aesthetic flexibility.

Disadvantages

- While 6063 T4 aluminum plate provides good strength for many applications, it may not be suitable for highly stressed structural components.

- Cost: Aluminum alloys can be more expensive than steel, although their performance characteristics often justify the cost.

6063 T4 aluminum sheet combines excellent formability, weldability, corrosion resistance and aesthetics, making it a versatile material choice for a variety of industrial and construction applications. Its properties and processing make it ideal for applications requiring lightweight, durable and aesthetically pleasing components.

6063 t4 Aluminum Plate Material Properties

| Property | Value |

| Alloy Composition | Aluminum, Silicon, Magnesium |

| Formability | Excellent |

| Workability | Good |

| Strength | Moderate |

| Corrosion Resistance | Good |

Mechanical Properties of 6063 T4 Aluminum Plate

| Product | 6063 T4 | 6063 T5 | 6063 T6 |

| Diameter(MM) | less than 150 | less than 200 | less than 150 |

| Tensile Strength(Mpa) | more than 130 | more than 175 | more than 195 |

| Yield Strength(Mpa) | more than 65 | more than 130 | more than 160 |

| Elongation | more than 14 | more than 8 | 10 |

It is important to note that the specific mechanical properties of 6063 T4 aluminum may vary depending on factors such as alloy composition, manufacturing process, dimensions, and testing standards. Consulting an aluminum supplier or manufacturer can provide more detailed and specific information based on your application requirements.

Physical Properties of 6063-T4 Aluminum Plate

| Property | Value |

|---|---|

| Density | 2.7 g/cm^3 |

| Melting Point | 606 - 655°C |

| Electrical Conductivity | Approximately 57% of copper's conductivity |

Thermal Properties of 6063-T4 Aluminum Plate

| Property | Value |

|---|---|

| Thermal Conductivity | 200 - 210 W/m·K |

| Coefficient of Thermal Expansion | 23.5 x 10^-6/°C |

6063 T4 aluminum is typically used in applications where formability and machinability are important, such as architectural and decorative applications, extruded profiles, and components that require bending or forming. It may not have the same level of strength as other tempers such as T6, but it offers improved formability for applications where these properties are a priority.

Typical 6063 T4 Aluminum Applications

- 6063 T4 Aluminium Sheet for Automotive Body Structural Parts

- 6063 T4 3C Digital Shell Aluminum Sheet

- 6063 T4 Aerospace Aluminum Profile Extrusions

- 6063 T4 Cabinet Handle Aluminum Profile

- 6063 T4 Aluminum Auto Profiles

- 6063 T4 Oil Tanker Aluminum Tube

- 6063 T4 Electrical Aluminum Busbar

6063 t4 aluminum manufacturing process

- Extrusion: 6063 aluminum alloy is typically processed by extrusion, where it is heated and forced through a die to form complex cross-sectional shapes such as beams, channels and tubes.

- Sheet Production: Sheet is typically produced by pouring molten aluminum into a rectangular mold and then hot rolling it to the desired thickness.

Heat treatment (T4 condition):

- Solution heat treatment: The alloy is heated to a temperature range of approximately 500-600°C (932-1112°F) to dissolve the soluble phase and homogenize the microstructure.

- Quenching: Rapid cooling of a material by quenching it in water or air to retain a supersaturated solid solution.

- Aging: Natural aging or artificial aging at room temperature or slightly elevated temperature to precipitate strengthening phases and thereby improve mechanical properties.

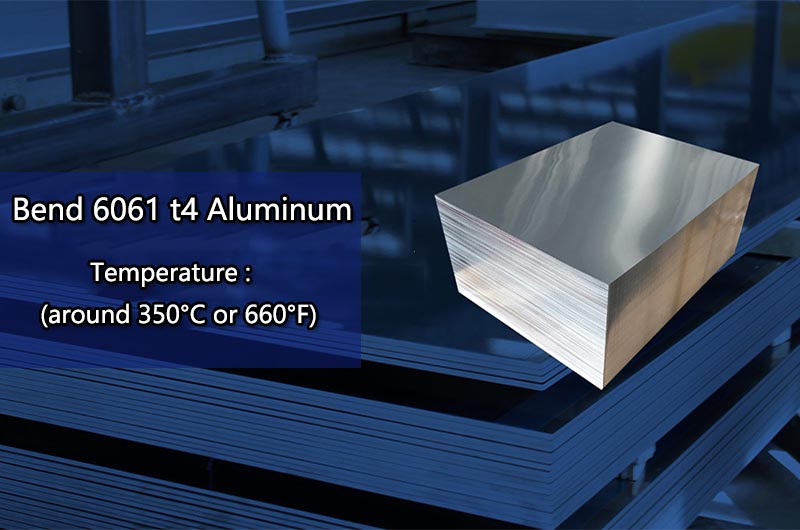

Bend 6061 t4 Aluminum

Bending 6061-T4 aluminum requires proper technique to ensure successful results. Here are some considerations for bending 6061-T4 aluminum:

- Material Selection: Make sure you have the right alloy and temper specification for your desired bending application. In this case, 6061-T4 aluminum is the specific alloy and temperature.

- Annealing: Consider annealing 6061-T4 aluminum before bending to improve its formability. Annealing involves heating a material to a specific temperature (around 350°C or 660°F) and then allowing it to cool slowly. This process softens the aluminum, making it more malleable and easier to bend.

- Tools and Equipment: Use bending equipment designed specifically for aluminum, such as a hydraulic press brake or a dedicated press brake. Make sure the tool has the proper tool radius and properly aligns the material during bending.

- Bending Radius: The bending radius refers to the curvature of the bend. Larger bend radii are generally preferred for aluminum to reduce the risk of cracking or warping. The exact bend radius required will depend on the thickness and size of the aluminum part.

- Lubrication: Apply lubricant to the surface of aluminum to reduce friction during bending and prevent surface damage. Suitable lubricants include specialized bending lubricants or even soapy water.

- Test bends: Perform test bends on scrap or samples of 6061-T4 aluminum to determine the proper setup and technique before bending the actual workpiece. This allows you to tweak parameters and ensure you get the desired result without damaging the final product.

6063 t4 vs t6 Aluminum Plate

Temper

- 6063-T4: The T4 temper involves solution heat treatment and natural aging to obtain the desired properties.

- 6063-T6: The T6 temper involves solution heat treatment followed by artificial aging to increase the strength of the material.

Mechanical Properties

| Property | 6063-T4 Aluminum | 6063-T6 Aluminum |

|---|---|---|

| Tensile Strength | 140 - 180 MPa | 205 - 240 MPa |

| Yield Strength | 70 - 160 MPa | 160 - 200 MPa |

| Elongation | 12 - 18% | 8 - 14% |

Strength

Compared to 6063-T4, 6063-T6 has higher tensile strength and yield strength, making it stronger and better suited for applications requiring higher mechanical strength.

Formability

Both 6063-T4 and 6063-T6 exhibit good formability, but the T4 temper offers slightly better formability due to its lower strength.

Applications

- 6063-T4: This temper is typically used for architectural and decorative applications, window frames, door frames, and other components requiring good formability and moderate strength.

- 6063-T6: This temper is typically used in structural applications that require higher strength, such as buildings, automotive parts, and structural framing.

NOTE: These properties are general and may vary based on specific alloy composition, manufacturing process, dimensions, and testing standards. Consultation with aluminum suppliers or manufacturers is recommended for accurate and current information specific to your application or project requirements.

What is the Difference between 6061 T4 and 6063 T4?

The main difference between 6061-T4 and 6063-T4 aluminum alloys is their composition and intended application. Here are some key differences:

Alloy Composition

- 6061-T4: This alloy consists primarily of aluminum, magnesium, and silicon, with other elements such as copper and chromium.

- 6063-T4: This alloy contains mainly aluminum, magnesium, and silicon, with small amounts of copper, chromium, and manganese.

Strength and Mechanical Properties

- 6061-T4: Compared with 6063-T4, it has higher tensile strength and yield strength. The T4 temper condition provides medium strength and formability.

- 6063-T4: It has slightly lower tensile and yield strengths than 6061-T4. The T4 temper condition provides good formability and machinability.

Applications

- 6061-T4: Commonly used in structural applications such as aircraft components, marine components, and high-strength structures requiring excellent corrosion resistance and high mechanical strength.

- 6063-T4: Commonly used in architectural and decorative applications, window frames, door frames, and other components requiring good formability and moderate strength.

Note: Specific mechanical properties and applications may vary depending on the manufacturing process, dimensions, and testing standards. Consultation with aluminum suppliers or manufacturers is recommended for accurate and current information specific to your application or project requirements.

People Also Searched about 6063 t4 Aluminum

- what is 6063 t6 aluminum

- 6063 t5

- aluminum 6063

- 6063 t6

- 6063 t6 aluminum properties

- 6063 t4 natural aging

- aluminum 6063 matweb

- 6063 alloy data sheet

- What is T4 aluminum used for?

- What is the difference between Aluminium 6063 T4 and T6?

- What is 6063 aluminum used for?