6082 Aluminum Plate Sheet

Temper: T4/T6/T651/O Competitive Prices

Aluminium Alloy 6082 Plate and Sheet Manufacturer

6082 aluminum plate is made of medium -intensity aluminum alloy. This material has good corrosion resistance and can be used for manufacturing components. These plates are mainly used for their good processing capabilities. Haomei Aluminum is a leading manufacturer and supplier of different types and sizes.

-

6082 T6 Aluminum Plate Sheet

6082 T6 Aluminum Plate Sheet has stable performance and complete specifications and can be customized according to customer needs.

-

6082 T651 Aluminum Plate Sheet

We strictly control the quality of the 6082 T651 Aluminum Plate Sheet, ensuring that each sheet meets the highest industry standards, stable performance, and competitive price.

-

6082 T4 Aluminum Plate Sheet

6082 T4 Aluminum Plate Sheet has strict quality control measures throughout the manufacturing process to ensure consistent quality

6082 aluminum alloys are usually made of squeezing and rolling, but as forging alloys, it is not used for casting. It can also be forged and covered, but this alloy is not common. It cannot process hardening, but it usually takes heat to generate high -intensity but low ductility.

6082 aluminum is an alloy in the 6000 series of aluminum alloys. It is a medium to high strength alloy whose strength and formability are enhanced by the addition of magnesium and silicon to its composition.

6082 and 6061 belong to aluminum-magnesium-silicon heat-treatable strengthened alloys, which have good extrusion processing and forging performance. It cannot be work-hardened, but it is usually heat-treated to produce a temper with higher strength but lower ductility.

6082 aluminum alloy is usually formed by extrusion and rolling, but as a wrought alloy, it is not used for casting. It can also be forged and clad, but this is not a common practice for this alloy.

ASTM B209 Aluminium Alloy 6082 Sheet

ASTM B209 Aluminium AlLoy 6082 Sheet chemical composition includes silicon, iron, copper, manganese, magnesium, zinc, titanium and chromium. The maximum yield strength of the board is 85MPa and the maximum tensile strength is 150MPa. The hardness level of this material is also 40 HB. The thickness of different forms of products such as coils, foil, belt, and 6082 T4 aluminum plate is 0.4mm to 6mm, and the length can reach 10000mm.

- Weldable-Gas: Good

- Weldable-arc: good

- Weldability-endurance: good

- Brazing property: Good

- Weldability: Good

- Processability-Cold: Good: Good

- Mechanical processing: good

Aluminum 6082 Plate Properties

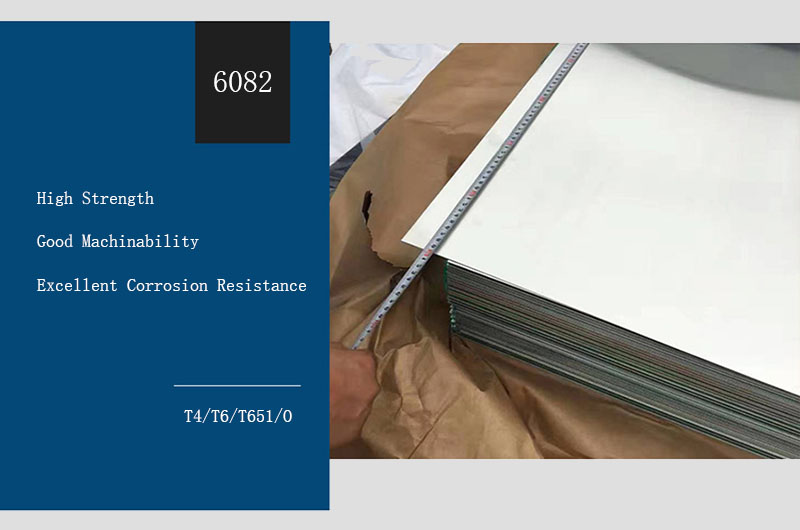

- High Strength: Compared to many other aluminum alloys, 6082 aluminum has higher strength, making it suitable for structural applications.

- Excellent Corrosion Resistance: This alloy exhibits good corrosion resistance, especially in marine environments. This makes it suitable for applications exposed to wet or harsh weather conditions.

- Good Machinability: 6082 aluminum is easy to machine and complex parts can be made.

- Weldability: The alloy has good weldability and can be joined by various welding techniques such as MIG, TIG, and resistance welding.

- Anodizing Capability: 6082 aluminum can be anodized to enhance its surface properties, including improved corrosion resistance and decorative properties.

Aluminium Alloy 6082 Plate Material Specification

| Grade | Aluminium 6082 / UNS A96082 |

| ASTM Specifications | ASTM B209 / ASME SB209 |

| Thickness Chart | 0.5mm TO 250mm |

| Form | Plates, Sheets, Slatting Coils, Coils, Foils, Plain Sheet, Shim Sheet, Strip, Rolls, Perforated Coils, Flats, Blank , Ring |

| Hardness | Quarter Hard, Soft, Hard, Half Hard, Spring Hard etc. |

| Finish | Cold rolled sheet (CR), 2D, Hot rolled plate (HR), 2B, BA NO(8), SATIN (Met with Plastic Coated) |

| Size in Milimeter | 000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm etc |

| Length in MM | 1000mm TO 6000mm |

| Applications Industries | Gas Processing, Condensers, Sea Water Equipment, Power Generation, Pharmaceuticals, Specialty Chemicals, Pulp, Pharmaceutical Equipment, Chemical Equipment, Petrochemicals, Paper Off-Shore Oil Drilling Companies, Heat Exchangers, Industry |

6082 Aluminum Alloy Data Sheet

Specific properties and dimensions of the 6082 Aluminum Plate Sheet may vary by manufacturer and desired application. It is available in various thicknesses, widths, and lengths to suit different requirements. When purchasing, be sure to specify the dimensions required and any other specifications such as temper (e.g. T6, T651) or surface finish.

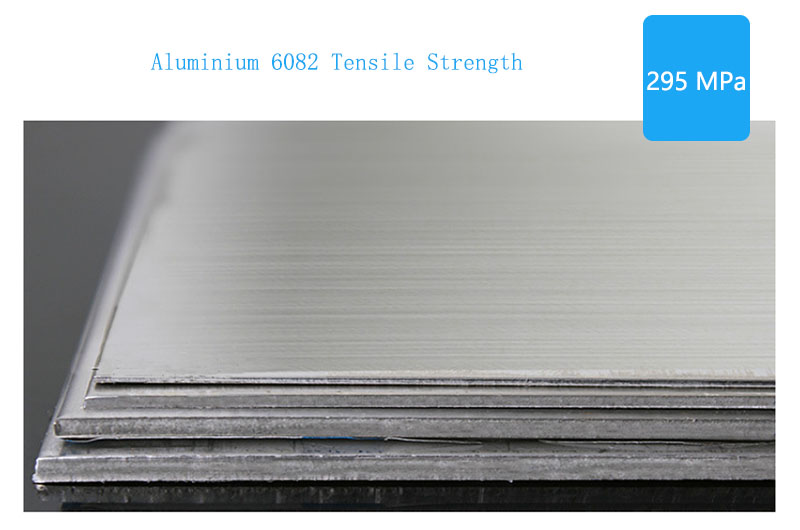

Aluminum 6082 Tensile Strength

The tensile strength of aluminum alloy 6082 in the T6 temper is typically around 295 MPa (42, 800 psi). This value represents the maximum stress the material can withstand before failing in tension.

Note: Actual tensile strength will vary slightly due to specific manufacturing processes, test conditions, material thickness, etc. It is always recommended to refer to the material data sheet or consult the manufacturer for precise tensile strength information.

Aluminum 6082 Chemical Composition

| Element | Weight Percentage (%) |

|---|---|

| Aluminium | 95.2 to 98.3 |

| Chromium | 0.25 % max. |

| Copper | 0.1 % max. |

| Iron | 0.5 % max |

| Magnesium | 0.6 to 1.2% |

| Manganese | 0.4 to 1.0 % |

| Silicon | 0.7 to 1.3% |

| Titanium | 0.1 % max |

| Zinc | 0.2 % max |

| residuals | 0.15 % max |

6082 Aluminum Equivalent

- ISO: Al SiMgMn ISO 209.1-1989

- Non-standard: 64430 IS 733-2001 IS 737-2001

- Russian standard: AII35/1350 ROCT 4785-1974

- EN: EN AW-6082/AlSiMgMn EN 573-3-1994

- German standard: AlMgSi/3.2315 DIN1725.1-1986/W-Nr

- French standard: 6082 (A-SGMO0.7) NF A50-411 NF A50-451

- American Standard: 6082/A96082 AA/UNS

- 6082 GB/T 3190-1996

Standard of 6082 Aluminum Plate

-

European Standards

- EN 573: Aluminum and aluminum alloys - Chemical composition and form of products.

- EN 485: Aluminum and aluminum alloys - Sheet, strip, and plate.

-

American Standards

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- ASTM B209M: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate (Metric).

-

International Organization for Standardization (ISO)

- ISO 209: Aluminum and aluminum alloys - Chemical composition and form of wrought products.

- ISO 6361: Wrought Aluminum and Aluminum Alloys - Sheets, Strips, and Plates.

These standards provide guidance for the chemical composition, mechanical properties, dimensions, and tolerances of aluminum alloy products including 6082. Manufacturers and suppliers often adhere to these standards to ensure the consistency and quality of their products.

When purchasing an aluminum alloy 6082 plate, sheet, or coil, it is recommended to check with the manufacturer or supplier to confirm the specific standards being followed, as well as any additional specifications or requirements.

6082 Aluminum Plate SheetMore Info

- Density = 2.70 g/cm³

- Melting Point = 555 °C

- Thermal Expansion = 24 x10^-6 /K

- Modulus of Elasticity = 70 GPa

- Thermal Conductivity = 180 W/m.K

- Electrical Resistivity = 0.038 x10^-6 Ω .m

- Proof Stress = 255 - 240 Min MPa

- Tensile Strength = 300 - 275 Min MPa

- Hardness Brinell = 91 - 84 HB

Basic Types Of Aluminium 6082 Plate

- 6082 Aluminum alloy Sheet

- 1 Inch Aluminum Plate 6082

- 6082 T6 10mm aluminum plate

- 6082 T6 decorative aluminum sheet

- aluminum sheet 6082 6xxx aluminum plate

- aluminum alloy 6082 plate

- 50mm 60mm Thick 6082 Aluminum Plate

- 6082 T6 10mm aluminum plate

- aluminum sheet 6082 6xxx aluminum plate

- 6082 T6 decorative aluminum sheet

- 6082 T6 decorative aluminum sheet

- 50mm 60mm Thick 6082 Aluminum Plate

- 1 Inch Aluminum Plate 6082

- 6082 T6 10mm aluminum plate

- 40mm thickness 6082 t6 aluminum plate

- 6082 Aluminum alloy Sheet

- 40mm thickness 6082 t6 aluminum plate

- 6082 T6 decorative aluminum sheet

- 6082 Aluminum alloy Sheet

- 6082 T6 decorative aluminum sheet

- aluminum sheet 6082 6xxx aluminum plate

- 1 Inch Aluminum Plate 6082

- aluminum alloy 6082 plate

- aluminum alloy 6082 plate

- 50mm 60mm Thick 6082 Aluminum Plate

- 40mm thickness 6082 t6 aluminum plate

- 6082 T6 decorative aluminum sheet

Typical 6082 Aluminum Plate

6082 O Aluminum Plate

- The O (annealed) temper refers to a completely soft material with low strength and high formability.

- 6082 O Aluminum has excellent machinability and is easy to form, bend, and shape.

- It is often used in applications that require complex molding or require high ductility.

- Mechanical properties such as yield strength and tensile strength are lower in 6082-O aluminum compared to other tempered conditions.

6082 T4 Aluminum Plate

- T4 temper designates solution heat-treated and naturally aged material.

- 6082 T4 Aluminum has medium strength and higher hardness compared to the annealed state.

- The T4 temper provides good formability and is typically used in applications requiring moderate strength and excellent corrosion resistance.

- 6082-T4 aluminum has higher a yield and tensile strength than the annealed (O) condition.

6082 T6 Aluminum Plate

- T6 temper designates solution heat-treated and artificially aged material.

- 6082 T6 Aluminum has high strength and excellent resistance to deformation.

- T6 tempers are often used in structural applications requiring a high strength-to-weight ratio, such as aerospace, automotive, and marine components.

- 6082-T6 aluminum has a higher yield and tensile strength than the T4 temper.

6082 T651 Aluminum Plate

- T651 Temper designates material that has been solution heat treated for stress relief by stretching.

- 6082 T651 Aluminum offers improved dimensional stability and reduced internal stress.

- T651 tempering is often used for precision parts or parts that require excellent dimensional accuracy and stability.

- The yield strength and tensile strength of 6082-T651 aluminum are comparable to the T6 temper.

It is important to note that the specific mechanical properties of each tempering condition may vary slightly, depending on the manufacturer and the size of the sheet or sheet. It is always recommended to refer to the material data sheet or consult the manufacturer for precise mechanical property information.

Usage of 6082 Aluminum Material Sheet

6082 Aluminum Plate Sheet refers to a flat plate or plate made of 6082 aluminum alloy. These plates/sheets are commonly used in various industries requiring high strength, light weight, and corrosion resistance, such as aerospace, transportation, marine, automotive, and structural applications.

- Aerospace industry: 6082 aluminum is used in the manufacture of aircraft structures, including wings, fuselage, and other structural components. Its high strength-to-weight ratio makes it suitable for reducing the overall weight of an aircraft while maintaining structural integrity.

- Automotive Industry: The automotive industry uses 6082 aluminum plate to manufacture body panels, chassis components, and structural parts. The alloy combines high strength and lightweight properties to help improve fuel efficiency and overall performance.

- Marine Applications: Due to its excellent corrosion resistance, 6082 aluminum plate is commonly used in the marine industry for the construction of hulls, decks, and other structural components. The material withstands exposure to salt water and provides durability in harsh marine environments.

- Building and construction: 6082 aluminum is used in a variety of applications in the construction sector, such as roofing, siding, window frames, and structural supports. Its strength and weather resistance make it a popular choice for both indoor and outdoor applications.

- Construction and architecture: 6082 aluminum is employed in the construction sector for various applications, such as roofing, wall panels, window frames, and structural supports. Its strength and resistance to weathering make it a popular choice for both interior and exterior applications.

- Sports equipment: 6082 aluminum is used to make sports equipment such as bicycle frames, ski poles, and rock climbing equipment. Its lightweight properties help improve performance while maintaining the necessary strength and durability.

- Industrial Machinery: This alloy is commonly used in the manufacture of industrial machinery components such as frames, brackets, and structural parts. Its high strength ensures stability and reliability in harsh industrial environments.

- Electrical Applications: Due to its excellent thermal conductivity, 6082 aluminum plates can be used in electrical enclosures, heat sinks, and bus bars. The material dissipates heat efficiently, making it suitable for applications where thermal management is critical.

- Precision Engineering: 6082 aluminum is used to manufacture precision components that require high strength and dimensional stability. It is commonly used in CNC machining, prototyping, and tooling applications.

1. 6082 Aluminum Plate for Coupler

6082 aluminum alloy plate is an aluminum alloy plate that can be heat treated and strengthened. It has good formability, excellent weldability, good processability, and corrosion resistance, and still maintains good operability after annealing. Therefore, the 6082 aluminum plate can be used in transportation couplers.

2. Liquefied Gas Tank Bracket 6082 Aluminum Plate

The following are the reasons for choosing the 6082 aluminum plate for the liquefied gas tank bracket:

- High Strength: Provides the required structural support for gas storage tanks.

- Corrosion Resistance: Protection against environmental factors, including exposure to liquefied gases.

- Lightweight: Reduce the overall weight of the fuel tank and vehicle.

3. 6082 Alloy Aluminum Plate for Automobiles

The following are the reasons why cars choose 6082 aluminum plates:

- Lightweighting: Reduce vehicle weight, thereby improving fuel efficiency.

- Formability: Allows for complex automotive part shapes.

- Corrosion Resistant: Protects against environmental conditions on the road.

4. 6082 Aluminum Plate for Tank Truck Protective Floor

The following are the reasons for choosing the 6082 aluminum plate for the protective floor of oil tankers:

- High Strength: Provides durability to protective flooring.

- Corrosion Resistance: Resists potential chemical and moisture exposure.

- Weldability: Able to be easily integrated into tanker structures.

5. 6082 Mold Aluminum Plate

The following are the reasons for choosing 6082 for mold aluminum plates:

- Machinability: Easily machined for mold production.

- Dimensional Stability: Maintains shape and size during molding.

- Wear Resistance: Suitable for repeated use in molding applications.

6. 6082 Aluminum Plate for Aluminum Alloy Bridge

The following are the reasons for choosing 6082 for aluminum alloy bridges:

- High Strength: ensure the integrity of the bridge structure.

- Corrosion Resistance: Protects against outdoor exposure and environmental factors.

- Long Life: Provides durable materials for long-lasting bridges.

7. 6082 Marine Aluminum Plate

The following are the reasons for choosing 6082 for marine aluminum plates:

- Corrosion Resistance: Critical for marine environments exposed to salt water.

- Strength: Provides necessary strength to ship components.

- Lightweight: Helps reduce the overall weight of marine structures.

8. 6082 Aluminum Plate for off-road Vehicle Floor Protection Plate

The following are the reasons for choosing 6082 for off-road vehicle floor protection plates:

- High Strength: Provides protection for off-road vehicles in rugged conditions.

- Corrosion Resistant: Protects from exposure to a variety of terrain and elements.

- Lightweight: Minimize the extra weight of your off-road vehicle.

In all these applications, 6082 aluminum alloy is chosen because of its combination of strength, corrosion resistance, lightweight properties, and formability, making it a versatile choice for a variety of manufacturing needs in different industries. Proper engineering and manufacturing techniques are critical to ensuring the effectiveness and safety of components made from 6082 aluminum alloy in these applications.

These are just a few examples of the many uses for 6082 aluminum plates. The alloy's combination of strength, lightweight, and corrosion resistance makes it a popular choice in a variety of industries and applications where these properties are essential.

Cast 6082 Aluminum Alloy

It is important to note that in aluminum casting, precise control of temperature, composition, and other parameters is crucial to avoid defects and ensure the quality of the final product.

1. Smelting: The smelting process involves melting aluminum alloy, the main considerations for this step are:

- Temperature Control: The melting temperature should be maintained within a specific range of 740-760°C. This temperature range ensures that the 6082 aluminum alloy melts properly without excessive oxidation or other problems.

- Stirring: Molten 6082 aluminum alloy must be stirred thoroughly to achieve uniformity of composition and temperature. Stirring prevents changes in alloy properties.

- Sampling: Sampling is critical to verify ingredients and temperature. Samples were taken from different points to ensure consistency.

- Composition Control: Once sample analysis confirms that the composition and temperature of the 6082 aluminum alloy are within the required range, the metal can proceed to the next step.

2. Purification and Casting

- Refining: After smelting, the molten alloy is transferred to a static furnace. Nitrogen and refining agents are introduced to remove impurities, gases, and slag. The refining temperature should be maintained at 735-745°C for 15 minutes. This step ensures the purity of the melt.

- Filtration: Filtration is essential to remove any remaining impurities. Two filtering devices are used between the casting mold and the furnace mouth. The foam ceramic filter plate (30PPI) at the furnace mouth helps filter the melt. Before pouring, use a 14-mesh glass fiber cloth to filter out oxides and slag inclusions to ensure that the melt is clean during pouring.

3. Casting

- Casting Temperature: Compared with some other aluminum alloys, the casting temperature of 6082 alloy aluminum plates is relatively high. Maintaining the correct temperature is critical to ensuring proper casting.

- Casting Speed: Keep the casting speed low to control the flow of molten metal and ensure the quality of castings. High casting speeds can cause defects.

- Water Flow: Controlling water flow is critical to properly cooling and solidifying molten metal. The cooling rate affects the final properties of the casting.

6082 aluminum plate in stock

| Procuct | Size (in) |

| ASTM B209 ASME SB209 1/4" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1/4" 6082 T6 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1/4" 6082 T651 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1/4" 6082 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1/4" 6082 T4 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1/4" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 3/8" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 3/8" 6082 T6 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 3/8" 6082 T651 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 3/8" 6082 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 3/8" 6082 T4 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 3/8" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 1/2" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1/2" 6082 T6 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1/2" 6082 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1/2" 6082 T651 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1/2" 6082 T4Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1/2" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 5/8" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 5/8" 6082 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 5/8" 6082 T6 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 5/8" 6082 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 5/8" 6082 T651 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 5/8" 6082 T4 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 3/4" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 3/4" 6082 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 3/4" 6082 T6 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 3/4" 6082 T6 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 3/4" 6082 T6 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 3/4" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1" 6082 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1" 6082 T651 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 1.25" 6082 T6 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1.25" 6082 T6 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1.25" 6082 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1.25" 6082 T6 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1.25" 6082 T6 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1.25" 6082 T6 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 1.5" 6082 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1.5" 6082 T6 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1.5" 6082 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1.5" 6082 T651 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1.5" 6082 T651Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1.5" 6082 T651Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 1.75" 6082 T651Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 1.75" 6082 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 1.75" 6082 T651Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 1.75" 6082 T651Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 1.75" 6082 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 1.75" 6082 Aluminum Plate | 24" X 36" |

| ASTM B209 ASME SB209 2" 6082 T4 Aluminum Plate | 12" X 12" |

| ASTM B209 ASME SB209 2" 6082 T4 Aluminum Plate | 12" X 24" |

| ASTM B209 ASME SB209 2" 6082 Aluminum Plate | 12" X 36" |

| ASTM B209 ASME SB209 2" 6082 T4 Aluminum Plate | 12" X 48" |

| ASTM B209 ASME SB209 2" 6082 T4 Aluminum Plate | 24" X 24" |

| ASTM B209 ASME SB209 2" 6082 T4 Aluminum Plate | 24" X 36" |

Dimensions Chart of Aluminium 6082 Coils

| Aluminum Sheet Surface finish Chart | Gauge (inch) | Width (max inch) |

| 2B – Cold rolled, pickled, heat treated, skin passed Sheet | 10–24 | 72* |

| 2D – Cold rolled, pickled plate, heat treated | 12–24 | 60 |

| BA Mexinox only | 18–28 | 48 |

| Polished plate/ sheet (not brushed) | 11–24 | 60 |

| Temper hot rolled plate Mexinox only | 13–29 | 48 |

People also searched for Aluminum Plate

-

6063 Aluminum Plate Sheet

6063 is often called building aluminum, and 6063 aluminum plate has excellent hardness and processability and excellent anode oxidation performance.

-

6063 T6 Aluminum Plate Sheet

Production Capacity: With advanced production facilities and equipment, the 6063 T6 aluminum plate produced is an aluminum plate with precise dimensions, a smooth surface, and consistent thickness. Able to meet the requirements of different customers, including customized sizes and specifications.

-

6063 T5 Aluminum Plate Sheet

6063 T5 Aluminum Plate Sheet suppliers should offer competitive prices without compromising product quality.

-

6063 T4 Aluminum Plate Sheet

6063-T4 aluminum has good formability and is suitable for various manufacturing processes such as bending, forming, and extrusion.