6082 T4 Aluminum Plate Sheet

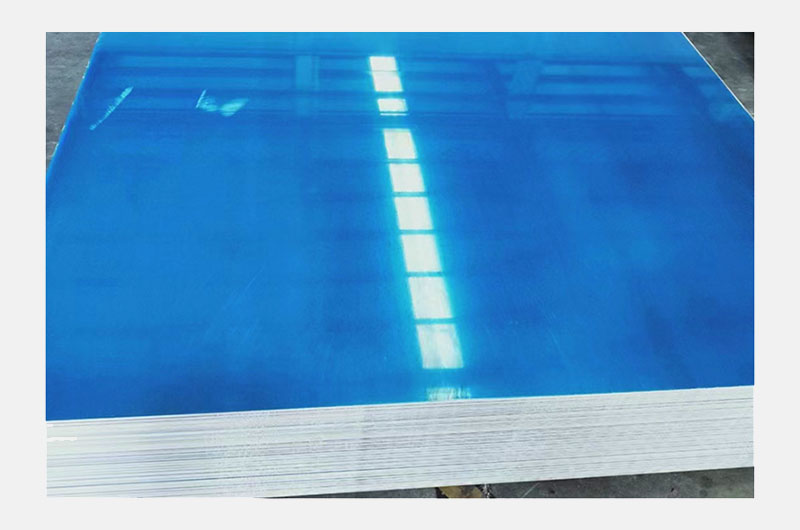

Dimensional Accuracy Smooth and Uniform Surface

Tempering conditions: The "T4" tempering mark indicates that the aluminum alloy has undergone solution heat treatment and natural aging. For 6082 aluminum, T4 This tempering process provides improved formability and ductility while still maintaining some level of strength.

The process to achieve the T4 temper involves heating the aluminum alloy to a specific temperature followed by rapid quenching in water or other cooling medium. This step, known as solution heat treatment, helps to dissolve any alloying elements and form a uniform solid solution.

6082 T4 aluminum plate belongs to the 6××× series (Al-Mg-Si) alloy aluminum plate. It is an aluminum alloy plate that can be heat treated and strengthened. It has medium strength, good welding performance and corrosion resistance.

After solution heat treatment, the aluminum is either naturally aged or aged at room temperature. This aging process helps to increase the strength and hardness of the alloy while maintaining a good balance of formability and corrosion resistance.

T4 tempering is often used for aluminum alloys with moderate strength and good formability. 6082 T4 Aluminum offers a balance of strength and ductility making it suitable for a variety of applications such as structural components, automotive components, and machinery.

6082 T4 Aluminum Plate Features

- Features: 6082-T4 aluminum can be easily formed, bent, and formed using standard techniques.

- Good corrosion resistance, weldability, and machinability.

- Excellent machinability.

It is important to note that while T4 is the common temper name for 6082 aluminum, the exact mechanical and physical properties may vary depending on factors such as the manufacturing process, alloy composition, and any subsequent treatments performed on the material.

Aluminium Alloy 6082 T4 Plate Material Specifications

| Grade | Aluminium 6082 / UNS A96082 |

| ASTM Specifications | ASTM B209 / ASME SB209 |

| Thickness Chart | 0.5mm TO 250mm |

| Form | Plates, Sheets, Slatting Coils, Coils, Foils, Plain Sheet, Shim Sheet, Strip, Rolls, Perforated Coils, Flats, Blank , Ring |

| Hardness | Quarter Hard, Soft, Hard, Half Hard, Spring Hard etc. |

| Finish | Cold rolled sheet (CR), 2D, Hot rolled plate (HR), 2B, BA NO(8), SATIN (Met with Plastic Coated) |

| Size in Milimeter | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm etc |

| Length in MM | 1000mm TO 6000mm |

Physical Properties of Aluminium 6082 t4

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 555 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 180 W/m.K |

| Electrical Resistivity | 0.038 x10^-6 Ω .m |

6082 T4 Aluminum Plate Mechanical Properties

The tensile strength of 6082 T4 aluminum plate is ≥205Mpa, the yield strength is ≥110Mpa, and the elongation is 14%.

6082-T4 aluminum is a T4 tempered alloy. Here is some information about 6082-T4 aluminum:

Mechanical Properties: Compared to other tempers, 6082-T4 aluminum has lower mechanical strength but higher formability and flexibility.

It generally has lower tensile and yield strengths than the T6 or T651 tempers.

Al 6082 T4 Quality Control

- Uniformity: Al 6082 T4 has a uniform microstructure and composition throughout the material. Achieved by proper melting and casting process.

- Heat Treatment: T4 Temper involves solution heat treatment and natural aging process. Accurate control of temperature and time during solution heat treatment to dissolve any alloying elements and achieve the desired microstructure.

- Dimensional Accuracy: Plates are manufactured to the required specifications with precise dimensions and tolerances.

- Surface treatment: The surface of the 6082 T4 Aluminum Plate Sheet has no defects such as scratches, dents, or cracks. The board has a smooth, uniform finish that meets specified requirements.

- Mechanical properties: The 6063 T4 aluminum plate should have the required mechanical properties including strength, ductility, and hardness. These properties were tested consistently across the board.

- Corrosion Resistance: Aluminum is known for its corrosion resistance and 6063 T4 aluminum should exhibit good corrosion resistance. Follow proper handling and storage practices to prevent surface corrosion or damage.

- Quality Control: Strict quality control measures are taken throughout the manufacturing process to ensure consistent quality.

ASTM B209 Aluminium Alloy 6082 t4 Sheet Chemical Structure

| Chemical Element | % Present |

| Manganese (Mn) | 0.40 - 1.00 |

| Iron (Fe) | 0.0 - 0.50 |

| Magnesium (Mg) | 0.60 - 1.20 |

| Silicon (Si) | 0.70 - 1.30 |

| Copper (Cu) | 0.0 - 0.10 |

| Zinc (Zn) | 0.0 - 0.20 |

| Titanium (Ti) | 0.0 - 0.10 |

| Chromium (Cr) | 0.0 - 0.25 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

6082 T4 Aluminum Plate Typical Applications

6082 T4 aluminum plate has medium strength and good corrosion resistance, and is lightweight, making it an ideal material for manufacturing high-speed ship components. Such as structural components, automotive components and aerospace components, etc.

The T4 temper of 6082 aluminum alloy is often used in applications requiring good formability and moderate strength. Some typical uses include:

- Automotive: It is used in automotive body panels, trim parts, and other parts that require formability and corrosion resistance.

- Furniture and Decorative Applications: 6082-T4 aluminum is used for furniture frames, decorative elements, and interior design applications.

- General Manufacturing: The alloy can be used in general manufacturing applications requiring formability and moderate strength, such as sheet metal parts, brackets, and lightweight structural components.

- Machinability: 6082-T4 aluminum has good machinability and is suitable for various machining operations such as drilling, milling, and turning.

6082 T4 Aluminum Alloy Other Applications

- 6082 T4 Aerospace Grade Aluminum Forgings

- 6082 T4 Automotive Aluminum Coil Strip Sheet

- 6082 T4 Aluminum Bar

- 6082 T4 Electrical Aluminum Busbar

6082 T4 Aerospace Grade Aluminum Forgings

Forgings made from 6082 T4 aluminum are used in components like aircraft structural parts, wing spars, and landing gear, where strength and lightweight properties are crucial.

6082 T4 Automotive Aluminum Coil Strip Sheet

Coil strips and sheets made from 6082 T4 aluminum can be used in automotive body panels, chassis components, and other structural parts.

6082 T4 Aluminum Bar

Aluminum bars made from 6082 T4 are used in a wide range of applications, including the construction industry for building and structural components, as well as in the manufacturing of machinery and equipment.

6082 T4 Electrical Aluminum Busbar

The use of 6082 T4 aluminum in busbars offers good electrical conductivity and corrosion resistance, making it suitable for electrical distribution and power transmission applications.

It is important to note that the specific properties and applications of 6082-T4 aluminum may vary by manufacturer and industry standards. It is recommended to consult the supplier or manufacturer for detailed technical information and availability of 6082-T4 aluminum products.

Aluminum 6082 t4 vs t6

The "T4" and "T6" designations refer to the different tempering conditions the alloy can withstand, each with its own mechanical properties and characteristics.

Aluminum 6082 t4

In T4 condition, 6082 aluminum is solution heat treated and naturally aged. This involves heating the alloy to a certain temperature and then quenching it in water or other media to cool it quickly. Thereafter, the alloy is allowed to age naturally at room temperature.

T4 temper gives the material good formability, but it may not have the highest level of strength compared to other temper conditions.

It has good mechanical properties and is suitable for applications where strength requirements are moderate and formability is important.

Aluminum 6082 t6

T6 tempering involves solution heat treating 6082 aluminum alloy followed by artificial aging. After solution heat treatment, the material is quenched and then artificially aged at high temperatures.

Due to the artificial aging process, this temper offers higher levels of strength and hardness than the T4 temper, making it suitable for applications where strength is critical.

The T6 temper also has good machinability and weldability, but may be less formable than the T4 temper.

The choice between T4 and T6 tempers of 6082 aluminum depends on the specific requirements of the application.

- If formability is a priority and moderate strength is acceptable, temper T4 may be preferred.

- If high strength is required as well as good machinability and weldability, the T6 temper would be more suitable.

People Also Searched about 6082 t4 Aluminum

- What is t4 6082 material?

- What is 6082 grade aluminium?

- Is 6061 or 6082 aluminium?

High Quality 6082 T4 Aluminum Plate Manufacturers

Haomei Aluminum 6082-T4 aluminum plate has excellent material selection, high technical level, skilled processing technology, good product quality, and more stable and reliable performance;

- Competitive price: In terms of price, several companies can be compared. The product price is relatively more affordable, and there are not too many circulation links. The specific price details can be obtained by clicking Consulting.

- Perfect after-sales science: After-sales problems are also issues that the majority of users are more concerned about. They are worried about after-sales procrastination, untimely response, and affecting the production cycle.

- Professionals: We have professionals who can reasonably customize the production plan based on the actual needs of users. The production schedule is fast, the delivery is timely, and there are professionals who can quickly solve problems for you throughout the process.