7075 Aluminum Plate Sheet

Temper: T6/T7/O Authentication: AS9100

7075 aluminum is a high-strength alloy that belongs to the 7000 series of superhard aluminum alloys.

7075 Aluminum Plate/Sheet is used in aerospace, aircraft, military and automotive applications. 7075 Aluminum is the strongest aluminum, with the strength of many steels while retaining the light weight and corrosion resistance of aluminum. 7075 Aluminum Plate is available in stock in full sizes and custom cut lengths.

7075 is one of the strongest aluminum alloys available, with an excellent strength to weight ratio. 707 Aluminum Plate is ideal for highly stressed aircraft components.

7075 Aluminum Alloy belongs to Al-Zn-Mg-Cu alloy, its composition:

- it is mainly composed of aluminum

- Zinc is the main alloying element, so the corrosion resistance is quite good.

- Adding a little magnesium alloy can make the material reach very high strength after heat treatment.

- Other elements, such as magnesium, copper, and chromium, are also present in smaller amounts.

7075 Aluminum is more embrittled than many other aluminum alloys but has significantly better corrosion resistance than the 2000 series alloys.

The plasticity of 7075 aluminum in the annealed and just quenched state is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04, and the stress corrosion performance of the plate is better than 7A04.

7075 aluminum is not as corrosion-resistant as some other aluminum alloys, especially in humid or salty environments. Therefore, it is often coated or treated to enhance its corrosion resistance.

Combining high strength, lightweight, and excellent machinability, the 7075 aluminum plate is often used in applications requiring high strength and lightweight. Its high strength-to-weight ratio makes it suitable for reducing the weight of overall structures while maintaining structural integrity.

7075 Aluminum Plate Properties

- After solution treatment, the plasticity is good, and the strengthening effect of heat treatment is particularly good.

- It has high strength below 150°C and has particularly good low-temperature strength.

- Welding performance is poor.

- There is a tendency of stress corrosion cracking, and double-stage aging can improve the ability for the alloy to resist stress corrosion cracking.

- It needs to be covered with aluminum or other protective treatment.

7075 Aluminum Plate for Sale

7075 aluminum plate can be produced in a variety of sizes, usually from a few millimeters to a few inches in thickness. Width and length dimensions can also vary according to the specific requirements of the application.

| Specifications | Value |

|---|---|

| Temper | O, T6, T651, T62, T652, T76, T7651, T73, T7351 |

| Thickness | 1.0-300mm |

| Width | 500-3000mm |

| Length | 1000-12000mm |

| Tolerance | Thickness: '+/-.012 to +/-.160 Depending on thickness |

| Width: '+.25 to +.3125 Depending on width and thickness | |

| Length: '+.25 to +.5 Depending on length and thickness | |

| Surface | Polished, bright, paper interlaced, single-sided film, double-sided film |

| Authentication | CE, ISO, SGS, AS9100 |

| Standard | ASTM B209, JIS, GB, DIN, EN, AMS-QQ-250/3, AMS-QQ-250/5, ISO 209 |

Depending on the desired appearance and function requirements, these sheets or panels can have different finishes such as milled finish (raw aluminum surface), brushed finish, or anodized finish.

-

7075 T6 Aluminum Plate Sheet

The 7075 T6 Aluminum Plate Sheet produced by us has a flat surface, smooth surface, no burrs, stable performance and competitive price.

-

7075 T651 Aluminum Plate Sheet

We have rich experience in producing 7075 T651 Aluminum Plate Sheet. The product has a flat surface and uniform thickness. The quality inspection meets the standards and the price is competitive.

-

7075 T7351 Aluminum Plate Sheet

The quality inspection of the 7075 T7351 Aluminum Plate Sheet conforms to the standard, the performance is stable, and it has relevant certifications for aluminum plates, such as ISO 9001, etc.

-

7075 T7451 Aluminum Plate Sheet

We have 7075 T7451 Aluminum Plate Sheet related certifications, such as ISO 9001, etc. There is no problem with the quality of the aluminum plate, and the specifications are complete.

7075 Aluminum Plate Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength (σb) | ≥ 560 MPa |

| 0.2% Yield Strength (σp0.2) | ≥ 495 MPa |

| Elongation (δ5) | ≥ 6% |

The terms "7075 T6", "7075 T651", "7075 T7" and "7075 0" refer to the different temper designations of 7075 aluminum sheet. These temper designations indicate the specific heat treatment and mechanical properties of the aluminum alloy. Here's a breakdown of each temper:

7075 T6 Aluminum Plate

- T6 means that the aluminum plate has undergone solution heat treatment and artificial aging treatment.

- This state provides a combination of high strength and good formability.

- 7075 T6 Aluminum Plate has excellent mechanical properties, including high tensile strength and hardness.

- The T6 state is widely used in aerospace, military, and structural applications.

7075 T651 Aluminum Plate

- T651 is similar to the T6 temper but includes additional stretching to reduce residual stresses.

- The "T651" temper improves dimensional stability and reduces distortion during machining.

- 7075 T651 Aluminum Plate has similar mechanical properties to T6, including high strength and hardness.

- T651 plates are typically used in applications requiring high precision and tight tolerances.

7075 T7 Aluminum Plate

- T7 tempering involves stabilization by overaging after solution heat treatment.

- This temper has a higher resistance to stress corrosion cracking than T6.

- The T7 board maintains high strength, but the hardness is slightly lower than T6.

- The T7 temper is typically used in applications where stress corrosion resistance is critical, such as aerospace components.

7075 0 Aluminum Plate

- The "0" state represents annealed or fully softened aluminum.

- The 7075 0 sheet is in its softest state and offers excellent formability.

- They have lower strength and hardness compared to other states.

- 7075 0 plate is primarily used where maximum formability is required before further processing or heat treatment.

NOTE: Specific mechanical properties, including tensile strength, yield strength, and elongation, may vary depending on the temper and thickness of the aluminum sheet.

Equivalent 7075 Materials

- 7075 Aluminum

- al7075

- AA 7075

- 7075 Material

- 7075Al

- UNS a97075

- 7075 Metal

7075 Al Physical Properties

| Property | Value |

|---|---|

|

7075 aluminium Density (ρ) |

2.81 g/cm3 (0.102 lb/cu in) |

| Mechanical properties | |

| Young's modulus (E) | 71.7 GPa (10, 400 ksi) |

| Tensile strength (σt) | 572 MPa (83.0 ksi) |

| Elongation (ε) at break | 11% |

| Poisson's ratio (ν) | 0.33 |

| 7075 aluminium hardness | 87 HRB |

| Electrical properties | |

| Volume resistivity (ρ) | 51.5 nOhm*m |

Heat Treatment of 7075 Aluminum Alloy

| Property | Value |

|---|---|

| Melting temperature (Tm) | 477 °C (891 °F) |

| Thermal conductivity (k) | 130–150 W/m*K |

| Linear thermal expansion coefficient (α) | 2.36*10−5 K−1 |

| Specific heat capacity (c) | 714.8 J/kg*K |

7075 Aluminum Alloy Plate Composition

| Element | Composition Range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Zinc (Zn) | 5.1 - 6.1 |

| Magnesium (Mg) | 2.1 - 2.9 |

| Copper (Cu) | 1.2 - 2.0 |

| Chromium (Cr) | 0.18 - 0.28 |

| Iron (Fe) | 0.50 |

| Silicon (Si) | 0.40 |

| Manganese (Mn) | 0.30 |

| Titanium (Ti) | 0.20 |

| Others (single) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

7075 Aluminum Plate Uses

AA7075, generally used in parts manufactured by CNC cutting, is suitable for aircraft frames and high-strength accessories. Representative uses include aerospace, mold processing, mechanical equipment, and fixtures.

Aerospace industry, blow molding (bottle) mold, ultrasonic plastic welding mold, golf head, shoe mold, paper mold, foam molding mold, dewaxing mold, template, fixture, mechanical equipment, mold processing, used to make high-end Aluminum alloy bicycle frame.

7075 Aluminum due to its strength is commonly used in:

- Aerospace and military applications, including aircraft structures, fuselage frames, wing skins, and missile components.

- 7075 aluminum plate is also used in sporting goods, such as bicycle frames, rock climbing equipment, firearm parts, etc.

- Al7075 can also be used in high-end bicycle wheels, automotive parts, and equipment, where strength and weight reduction are key factors.

- 7075 aluminum plate is also used in the automotive industry for parts that require high strength, and lightweight, such as chassis components, suspension components, and engine mounts.

- It is also used in the production of high-performance machinery, marine equipment, and precision instruments.

It is especially used in the manufacture of aircraft structures and other high-stress structures that require high strength and strong corrosion resistance.

Forging 7075 Aluminum

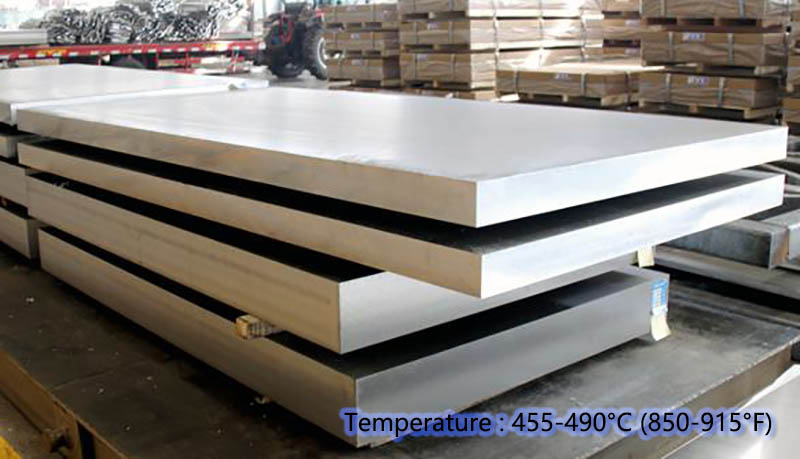

Forging is a common method of forming 7075 aluminum alloy. However, due to the high strength and low ductility of 7075 aluminum, there are some important considerations to keep in mind when forging this alloy:

- Temperature: It is critical to heat the 7075 aluminum to the proper forging temperature. Recommended forging temperatures for 7075 Al is typically in the range of 455-490°C (850-915°F). Heating the material to this temperature range increases its plasticity and reduces the risk of cracking during forging.

- Deformation Rate: Control the deformation rate during forging to avoid excessive strain and the associated risk of cracking. Slow and uniform deformation rates are generally preferred to minimize stress concentrations and maintain material integrity.

- Mold Design: Proper mold design is critical to achieve the desired shape and minimize defects. Molds should have suitable radii and rounded corners to minimize stress concentration points. It is also important to ensure proper lubrication to facilitate the forging process and prevent surface damage.

- Post-forging heat treatment: After forging, 7075 Al can be solution heat treated and then artificially aged to optimize its mechanical properties. This heat treatment process helps improve the strength and performance of forged components.

- Testing and Inspection: Forged components should be thoroughly tested and inspected such as ultrasonic testing, visual inspection, and dimensional inspection to ensure their quality and integrity.

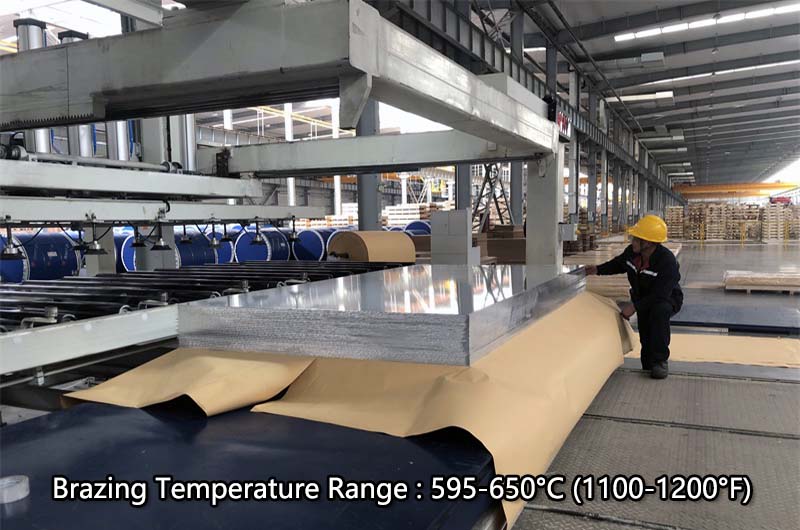

Brazing 7075 Aluminum

Welding 7075 aluminum is challenging due to its high strength and heat sensitivity. However, due to the high strength and low melting point of 7075 aluminum, special considerations are required when brazing this alloy. There are a few key points to keep in mind when brazing 7075 aluminum:

- Choice of Braze Alloy: Choose a braze alloy that is compatible with 7075 aluminum. Common filler alloys for brazing 7075 aluminum include 4043 and 5356. These filler alloys have lower melting points than 7075 Al, allowing them to flow and bond with the base metal during brazing.

- Cleaning and Preparation: Thoroughly clean the surfaces to be brazed to remove any contamination such as oil, grease, or oxides. Surface preparation is critical to ensure good wetting and proper bonding between the filler alloy and the base metal. Mechanical cleaning methods, chemical cleaning methods, or a combination of both can be used.

- Brazing Temperature and Time: Pay close attention to brazing temperature and time to achieve a successful connection. The brazing temperature should be above the melting point of the filler alloy but below that of the base metal (7075 Al). Typically, the brazing temperature range for 7075 Al is approximately 595-650°C (1100-1200°F). The duration of the brazing process depends on the joint configuration and the specific filler alloy used.

- Use of Flux: Apply an appropriate flux to the joint area before brazing to remove oxides and facilitate the flow of the filler alloy. Fluxes designed for aluminum brazing, such as chloride or non-corrosive fluxes, help promote clean and sound joints.

- Joint Design and Clearance: Consider the joint design and provide sufficient clearance for the filling alloy to flow into the joint. Proper clearance is important to ensure capillary action and create a strong brazed joint.

- Post-braze treatment: After brazing, post-braze treatments such as cleaning, inspection, and heat treatment may be required to relieve residual stress and optimize the mechanical properties of the brazed joint.

Milling 7075 Aluminum

Milling is a common machining process used to form and cut 7075 aluminum alloys. Here are some important considerations when milling 7075 aluminum:

- Tool Selection: Choose cutting tools specifically designed for aluminum machining. High-speed steel (HSS) or carbide tools with sharp cutting edges and appropriate coatings such as TiN or TiAlN are typically used for milling 7075 Al. Carbide-cutting tools are generally favored due to their excellent wear resistance.

- Cutting Speed and Feed Rate: Optimize the cutting speed and feed rate for efficient material removal and to prevent excessive tool wear. For aluminum, higher cutting speeds and feeds are generally recommended to achieve better chip evacuation and avoid built-up edge (BUE) formation. Consult the tool manufacturer for recommendations and adjust parameters for your specific milling setup and conditions.

- Coolants and Lubrication: The use of coolants or lubricants during milling helps to dissipate heat, improve surface finish, and extend tool life. Flood coolant or mist coolant systems are often employed to keep the cutting zone cool and lubricate the cutting action.

- Clamping and Rigidity: Ensures that the workpiece is properly clamped and secured to maintain stability and minimize vibration during milling. Rigidity is critical to achieving precise cuts and preventing chatter, especially when machining high-strength materials such as 7075 aluminum.

- Chip control: Pay attention to chip control to prevent chip recutting and tool blockage. Proper chip evacuation is critical to maintaining cutting efficiency and surface finish. Consider using chip breakers, chip evacuation systems, or high-pressure coolant to assist with chip control.

- Surface finish: The choice of milling strategy, such as climb or conventional milling, affects the surface finish of the milled part. Climb milling generally produces a smoother surface finish, while conventional milling may provide better chip control. Experimentation and testing can help determine the best milling strategy for your particular application.

- Workpiece Support: Provide adequate support for the workpiece to minimize vibration and deflection. Properly securing or using a machining center with a rigid structure helps maintain dimensional accuracy and surface finish.

- Tool Inspection and Replacement: Regularly inspect cutting tools for wear and damage and replace them if necessary. Worn or damaged tools can negatively impact cutting performance and lead to poor surface finish or inaccurate dimensions.

UNS A97075 aluminum plate Stock list

| Product | Thickness/in |

| Aluminum Sheet 7075-O-Clad | 0.025" |

| Aluminum Sheet 7075-O-Clad | 0.032" |

| Aluminum Sheet 7075-T6 | 0.032" |

| Aluminum Sheet 7075-T6 | 0.02" |

| Aluminum Sheet 7075-T6-Clad | 0.032" |

| Aluminum Sheet 7075-T6 | 0.04" |

| Aluminum Sheet 7075-O | 0.032" |

| Aluminum Sheet 7075-O-Clad | 0.04" |

| Aluminum Sheet 7075-T6 | 0.025" |

| Aluminum Sheet 7075-T6-Clad | 0.02" |

| Aluminum Sheet 7075-T73 | 0.032" |

| Aluminum Sheet 7075-T6 | 0.05" |

| Aluminum Sheet 7075-O-Clad | 0.05" |

| Aluminum Sheet 7075-O | 0.05" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | 1.000" |

| Aluminum Sheet 7075-O-Clad | 0.063" |

| Aluminum Sheet 7075-T6 | 0.063" |

| Aluminum Sheet 7075-T6-Clad | 0.063" |

| Aluminum Sheet 7075-O-Clad | 0.08" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .125" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .190" |

| Aluminum 7075-T6 Precision Ground Blanks | .125" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .250" |

| Aluminum Sheet 7075-T73 | 0.05" |

| Aluminum Sheet 7075-T73 | 0.04" |

| Aluminum 7075-T651 Precision Ground Blanks | .190" |

| Aluminum Sheet 7075-T73 | 0.08" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .375" |

| Aluminum Sheet 7075-O-Clad | 0.09" |

| Aluminum 7075-T651 Precision Ground Blanks | .250" |

| Aluminum Sheet 7075-T6 | 0.09" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .500" |

| Aluminum Sheet 7075-T73 | 0.025" |

| Aluminum Sheet 7075-T6-Clad | 0.08" |

| Aluminum Sheet 7075-T73 | 0.063" |

| Aluminum Sheet 7075-T6-Clad | 0.071" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .625" |

| Aluminum Sheet 7075-T6 | 0.071" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | 1.500" |

| Aluminum Sheet 7075-O-Bare | 0.1" |

| Aluminum Sheet 7075-T6 | 0.08" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .750" |

| Aluminum Sheet 7075-O-Clad | 0.1" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | 2.000" |

| Aluminum Sheet 7075-T6-Clad | 0.09" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | .875" |

| Aluminum Sheet 7075-T73 | 0.032" |

| Aluminum Sheet 7075-T6-Clad | 0.125" |

| Aluminum 7075-T651 Precision Ground Blanks | .375" |

| Aluminum Sheet 7075-T6-Clad | 0.1" |

| Aluminum 7075-T651 Precision Ground/Milled Blanks | 1.250" |

| Aluminum Sheet 7075-T6 | 0.125" |

| Aluminum Sheet 7075-T6 | 0.1" |

| Aluminum Sheet 7075-T73 | 0.125" |

| Aluminum 7075-T651 Precision Ground Blanks | .500" |

| Aluminum Sheet 7075-T73 | 0.09" |

| Aluminum 7075-T651 Precision Ground Blanks | .625" |

| Aluminum Sheet 7075-O-Clad | 0.125" |

| Aluminum Sheet 7075-O-Bare | 0.125" |

| Aluminum 7075-T651 Precision Ground Blanks | .750" |

| Aluminum Sheet 7075-T6-Clad | 0.16" |

| Aluminum 7075-T651 Precision Ground Blanks | 1.000" |

| Aluminum Plate 7075-T651 | 0.25" |

| Aluminum Sheet 7075-T6 | 0.19" |

| Aluminum Sheet 7075-T6 | 0.16" |

| Aluminum Sheet 7075-O | 0.09" |

| Aluminum Sheet 7075-T73 | 0.19" |

| Aluminum Plate 7075-T651 | 0.375" |

| Aluminum Plate 7075-T7351 | 0.25" |

| Aluminum Plate 7075-T651 | 0.3125" |

| Aluminum Plate 7075-T7351 | 0.5" |

| Aluminum Plate 7075-T651 | 0.5" |

| Aluminum Plate 7075-T7351 | 0.375" |

| Aluminum Plate 7075-T7351 | 0.5" |

| Aluminum Sheet 7075-T73 | 0.071" |

| Aluminum Plate 7075-T651 | 1" |

| Aluminum Plate 7075-T651 | 0.625" |

| Aluminum Plate 7075-T651 | 0.75" |

| Aluminum Plate 7075-T7351 | 1" |

| Aluminum Plate 7075-T7351 | 0.625" |

| Aluminum Plate 7075-T7351 | 0.75" |

| Aluminum Plate 7075-T7351 | 1.25" |

| Aluminum Plate 7075-T651 | 1.25" |

| Aluminum Plate 7075-T651 | 1.5" |

| Aluminum Plate 7075-T6 | 1.75" |

| Aluminum Plate 7075-T7351 | 1.5" |

| Aluminum Plate 7075-T7351 | 1.75" |

| Aluminum Plate 7075-T7351 | 2" |

| Aluminum Plate 7075-T7351 | 2" |

| Aluminum Plate 7075-T651 | 2" |

| Aluminum Plate 7075-T7351 | 2.25" |

| Aluminum Sheet 7075-O | 0.071" |

| Aluminum Plate 7075-T7351 | 2.75" |

| Aluminum Plate 7075-T7351 | 2.5" |

| Aluminum Plate 7075-T651 | 3.25" |

| Aluminum Plate 7075-T7351 | 3" |

People Also Searched about 7075 Aluminum

- 7075 aluminum vs 6061

- 7075 aluminum price

- 7075 aluminum bar

- 7075 aluminum tubing

- 7075 aluminum sheet

- 7075 aluminum vs steel

- 7050 vs 7075 aluminum

- which is better 6061 or 7075 aluminum

- 7071 vs 7075 aluminum

- how strong is 7075 aluminum

- 2024 vs 7075 aluminum

- 6061 vs 7075 aluminum bike frame

- t6 7075 aluminum

- t6 7075 aluminum properties

- 6065 vs 7075 aluminum

- 7075 t6 aluminum

- 7075-t6 aluminum material properties

- 7075-t6 aluminum suppliers

- 7075-t6 aluminum vs 6061

- 7075-t651 aluminum properties

- 7075 billet aluminum

- 7075 vs 7050 aluminum

- 7075-t6 forged aluminum

People also searched for Aluminum Plate

-

2017 Aluminum Plate Sheet

2017 aluminum plate is a heat-treatable forged aluminum product with good strength, ductility and good workability.

-

2219 Aluminum Plate Sheet

2219 aluminum alloy is a high-strength alloy, high temperature resistant and good cutting processing and good mechanical properties. 2219 aluminum plates are in line with AMS QQ-A-250/30. Common TEMPER includes T31, T81, O, etc.

-

2024 Aluminum Plate Sheet

2024 aluminum is a prominent hard aluminum alloy in the aluminum-copper-magnesium series. 2024 aluminum plates are famous for their high strength and excellent fatigue resistance, as well as their ability to be easily processed and welded.

-

2024 t851 Aluminum Plate Sheet

2024 T851 aluminum is commonly used in aerospace and military applications, such as the construction of aircraft structural components, due to its excellent strength-to-weight ratio and fatigue resistance.

-

2024 T3 Aluminum Plate Sheet

2024 T351 aviation aluminum plate is a high-strength aviation aluminum alloy material. T351 has large surface and internal residual stress and good explosion impact resistance. 2024 t351 is one of the aviation aluminum alloys. It is widely used in skins, bulkheads and structural parts that need to withstand high cyclic loads on various aircraft.

-

2024 T4 Aluminum Plate Sheet

2024 T4 aluminum has a high strength-to-weight ratio and good fatigue resistance, making it a popular choice for aerospace and structural applications. It also has good machinability and weldability, although it is not as corrosion resistant as some other aluminum alloys.

-

2618 Aluminum Plate

2618 aluminum is a high-strength aluminum alloy primarily used in applications requiring excellent mechanical properties, especially in high temperature and high stress environments.

-

2014 Aluminum Plate Sheet

2014 Aluminum Alloy is a popular aluminum alloy, especially in the aerospace industry, where 2014 T6 Aluminum is often preferred when maximum strength is required.

-

2011 Aluminum Alloy

Aluminum alloy 2011 is a free-machining aluminum alloy with excellent machining characteristics. It is part of the 2000 series of aluminum alloys.