7075 T651 Aluminum Plate Sheet

Stable Performance Strict Control of Tolerances

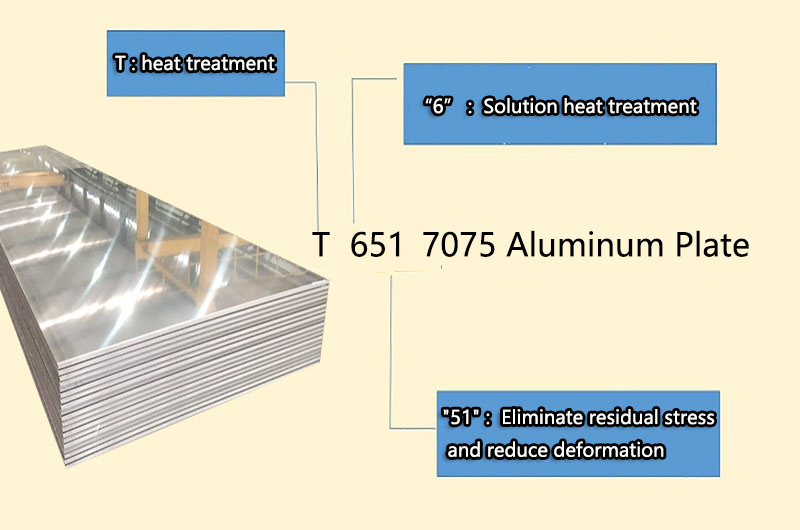

What is Aluminum 7075 T651?

7075-T651 is a specific temper designation for aluminum alloy 7075. The "T651" temper indicates that the aluminum has been solution heat treated, tensile stress relieved, and artificially aged to achieve its required properties.

The following are details for tempering specified components:

- "T" - Indicates that the aluminum alloy has been heat-treated, which involves heating the material to a specific temperature range, followed by rapid cooling.

- "6" - Indicates that the aluminum has been solution heat treated. The process involves heating the material to a temperature at which the alloying elements dissolve into the aluminum matrix, followed by rapid cooling to retain the desired properties.

- "51" - indicates that the aluminum has been stretched or permanently deformed to eliminate the residual stress after solution heat treatment. This process helps to increase dimensional stability and reduce deformation.

The T651 temper is known for providing high strength and excellent mechanical properties to aluminum alloy 7075. It is typically used in applications requiring a combination of strength, toughness, and fatigue resistance. Examples include aerospace components, high-performance sporting goods, and precision mechanical parts.

It is worth noting that the T651 temper is only one of many available tempers for aluminum alloy 7075. Other tempers such as T6 or T73 may have slightly different mechanical properties and processing conditions.

7075-t651 Aluminum Properties

| Property | Value |

|---|---|

| Tensile Strength | 570 - 640 MPa |

| Yield Strength | 500 - 570 MPa |

| Hardness | 150 HB |

| Elastic Modulus | 70 GPa |

| Density | 2.81 g/cm³ |

- Corrosion Resistance: 7075-T651 aluminum has good corrosion-resistance, but it is not as corrosion resistant as some other aluminum alloys. It is susceptible to localized corrosion in some environments and protective measures such as anodizing or coatings may be required to enhance corrosion protection.

- Machinability: 7075-T651 aluminum is generally considered to have moderate to poor machinability. Compared to some other aluminum alloys, it is more challenging to machine due to its high hardness and tendency to produce small chips during cutting operations.

These properties make 7075-T651 Aluminum suitable for a variety of applications requiring high strength, lightweight, and good stiffness. It is commonly used in aerospace components, military equipment, high-performance sporting goods, precision machinery, and other demanding applications requiring superior mechanical properties.

What is the Spec of 7075 T651?

Specifications for 7075-T651 aluminum are governed by various standards and specifications developed by organizations such as ASTM International, SAE International, and the Aluminum Association. Here are some common reference specifications for 7075-T651 aluminum:

- ASTM B209: This specification covers aluminum and aluminum alloy sheets and plates. ASTM B209 includes 7075-T651 Chemical Composition, Mechanical Properties, and Dimensional Tolerances for Aluminum.

- AMS 4045: This specification is specific to aluminum alloy plate and plate, 7075-T651. It covers requirements for chemical composition, mechanical properties, heat treatment, and quality assurance.

- SAE AMS-QQ-A-250/12: This specification covers the requirements for an aluminum alloy 7075-T651 plate. It provides detailed information on chemical composition, mechanical properties, and heat treatment.

These specifications outline the requirements and standards for 7075-T651 aluminum, ensuring consistency and quality in its manufacture, performance, and use.

7075 t651 Aluminum for Sale

| Thickness | 1.0-300mm |

|---|---|

| Width | 500-3000mm |

| Length | 1000-12000mm |

| Tolerance | Thickness: '+/-.012 to +/-.160 Depending on thickness |

| Width: '+.25 to +.3125 Depending on width and thickness | |

| Length: '+.25 to +.5 Depending on length and thickness | |

| Surface | Polished, bright, paper interlaced, single-sided film, double-sided film |

| Authentication | CE, ISO, SGS, AS9100 |

| Standard | ASTM B209, JIS, GB, DIN, EN, AMS-QQ-250/3, AMS-QQ-250/5, ISO 209 |

| Alloy | Thickness | Thickness Range |

|---|---|---|

| 7075 t651 Aluminum | Thin Sheets | 0.5 mm (0.020 in) - 2.0 mm (0.080 in) |

| 7075 t651 Aluminum | Medium Plates | 2.0 mm (0.080 in) - 25.4 mm (1.0 in) |

| 7075 t651 Aluminum | Thick Plates | 25.4 mm (1.0 in) and above |

Fatigue of 7075-t651 Aluminum Alloy

The 7075-T651 aluminum alloy exhibits good fatigue strength, that is, the ability to withstand repeated load cycles without failure. The fatigue performance of 7075-T651 is influenced by many factors including the specific application, loading conditions, surface finish, and other environmental factors.

In general, 7075-T651 aluminum alloy has higher fatigue strength than many other aluminum alloys. It is known for its excellent tensile strength and good fracture toughness, which contribute to its fatigue resistance. However, it is worth noting that fatigue strength may vary depending on specific heat treatment, processing, and fabrication conditions.

In order to evaluate the fatigue behavior of 7075-T651 aluminum alloy in specific applications, it is necessary to perform fatigue tests using representative loading conditions and sample geometries. Fatigue testing involves subjecting a specimen to cyclic loading (usually at different stress levels) and measuring the number of cycles to failure.

The fatigue performance of 7075-T651 aluminum alloy can be further improved by various techniques such as shot peening, surface treatment, and microstructure control through the heat treatment process. These techniques help improve fatigue life and increase the durability limit of the alloy.

It is important to consult a materials expert and refer to the specific fatigue data or standards relevant to your application for more accurate and detailed information on the fatigue performance of 7075-T651 aluminum alloy in your specific usage scenario.

Aluminum 7075 t651 vs t7351

7075-T651 and 7075-T7351 are two different states of 7075 aluminum alloy. Let's explore the differences between them:

7075-T651:

- T651 is a stress relief temper that involves stretching the material after solution heat treatment to reduce residual stresses, followed by artificial aging.

- This temper provides good mechanical properties, high strength, and good resistance to stress corrosion cracking.

- T651 has excellent machinability and is often used in applications requiring strength and corrosion resistance.

7075-T7351:

- T7351 is a stress relief temper that involves stretching the material after solution heat treatment to reduce residual stresses and then stabilizing it through an artificial aging process.

- This temper provides increased resistance to stress corrosion cracking compared to T651.

- T7351 has high strength and good machinability for applications requiring both strength and corrosion resistance.

In summary, the main difference between 7075-T651 and 7075-T7351 is their stress relief process and resulting resistance to stress corrosion cracking. While both tempers have high strength and good machinability, T7351 has enhanced resistance to stress corrosion cracking. The choice between the two tempers depends on the specific application requirements and the level of stress corrosion cracking resistance desired.

What is the Difference between 7075-T6 and 7075 T651?

Aluminum 7075 t6 vs t651

| Property | 7075-T6 | 7075-T651 |

|---|---|---|

| Temper | Solution Heat Treated and Artificially Aged | Stress Relieved and Artificially Aged |

| Strength | High strength | High strength |

| Machinability | Good | Good |

| Fatigue Resistance | Excellent | Excellent |

| Stress Corrosion Cracking Resistance | Lower | Higher |

| Tensile Strength | Around 570 MPa (83 ksi) | Around 570 MPa (83 ksi) |

The main difference between 7075 T6 and 7075-T651 is the tempering process and resulting stress relief.

While both tempers have high strength and good mechanical properties, T651 offers increased resistance to stress corrosion cracking due to the stress relief process.

The choice between the two depends on specific application requirements, including the need for stress corrosion resistance.

Which is Better 7075 T651 or 6061 T6?

The choice between the 7075 T651 and 6061 T6 depends on the specific application and requirements. Both alloys are commonly used in the aerospace, automotive, and general engineering industries, but they have different properties and strengths.

- 7075 T651 is a high-strength aluminum alloy known for its excellent strength to weight ratio. It has excellent mechanical properties, including high tensile strength and good fatigue resistance. This alloy is commonly used in applications requiring high strength, such as aircraft structures, aerospace components, and high-performance machinery. It is worth noting, however, that 7075 T651 has lower corrosion resistance than some other aluminum alloys.

- 6061 T6, on the other hand, is a general purpose aluminum alloy that offers a balance of strength, weldability, and corrosion resistance. It has good formability and machinability, making it a versatile choice for a variety of applications. It is commonly used in structural components, marine accessories, transportation equipment, and consumer products. While 6061 T6 is not as strong as 7075 T651, it still has satisfactory strength and is easier to process for fabrication and welding.

In summary, if you need high strength and are willing to compromise slightly on corrosion resistance, 7075 T651 may be the first choice. However, if you need a general purpose alloy with good strength, weldability, and corrosion resistance, 6061 T6 is a good choice. Ultimately, it is important to consider the specific needs of your application and consult with a materials engineer or industry expert to determine the best option