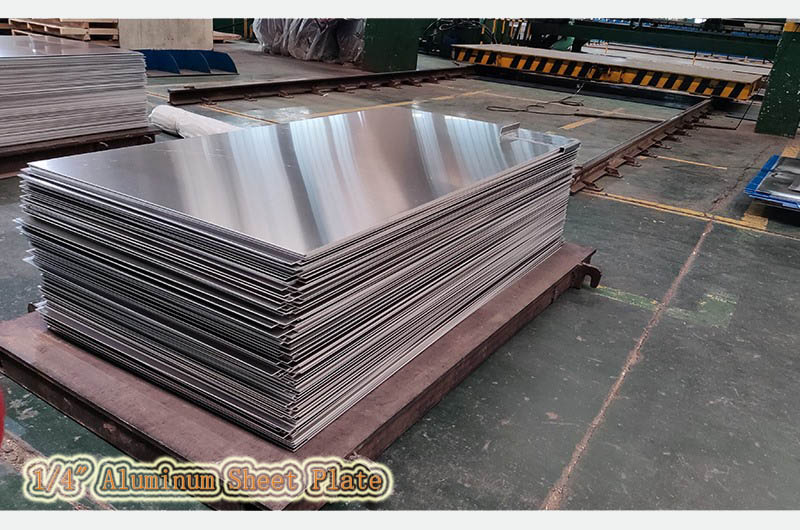

1/4" Aluminum Sheet Plate

Alloys: 6061/5052/7075 Precise Cutting to Specifications

1/4" Aluminum Sheet Plate refers to an aluminum plate with a thickness of 0.25 inches, which is equivalent to 6.35mm. This thickness belongs to aluminum

Plate thickness range, so 1/4" Aluminum Sheet can also be called 1/4" Aluminum Plate.

1/4" Aluminum Sheet Plates are commonly used in a variety of industrial, commercial, and consumer applications. For example, they are used in the manufacture of aircraft, ships, and automobiles, as well as building facades, decorative elements, and kitchen equipment.

When selecting 1/4" aluminum sheet, it is important to consider the specific requirements of the application, such as load-bearing capacity, weather resistance, and appearance. Sheets may also need to be cut or fabricated to fit specific sizes and shapes for a project, and this should also be considered when selecting a supplier. Take this into consideration.

1/4 inch Aluminum Plate for Sale

1/4" aluminum sheet specifications may vary by specific product and supplier. However, for a typical 1/4" aluminum plate, here are some general specifications:

Typical 1/4 Inch Aluminum Plate

Common standard sizes are:

- 1/4 inch aluminum plate 4x8 feet (48 inches by 96 inches)

- 1/4 inch aluminum plate 5x10 feet (60 inches by 120 inches)

- 24 x 24 x 1/4 aluminum plate

- 12 x 12 x 1/4 aluminum plate

But can also be customized to specific sizes.

Certified

Depending on the intended use, aluminum sheet may need to meet certain certifications or standards, such as ASTM or AMS. Always check with the supplier to ensure that the plate meets your specific requirements.

Surface Treatment

Depending on the intended use, the surface of the sheet can be untreated, polished, anodized or coated with a protective layer.

Package

Aluminum sheets are usually packaged with a protective layer to prevent scratches and damage during shipping and handling. The plates can be stacked and secured with straps or placed in a crate for extra protection.

Equivalent to 1/4 Aluminum Sheet Plate

- 1 4 aluminum plates

- 1 4 inch aluminum plate

- 1 4 inch thick aluminum plate

- 1 4 aluminum sheets

- 1 4 inch aluminum sheet

- 1 4 inch thick aluminum sheet

All of the above are 1/4" Aluminum Sheet Plate, but different regions have different expression habits.

1 4 Thick Aluminum Plate Typical Alloy

Alloy: Aluminum sheet can be made from a variety of alloys, 6061 and 7075 are commonly used in structural applications due to their high strength to weight ratio.

It's also important to note that the specifications for 1/4" aluminum sheet may vary by specific product and supplier, so be sure to confirm exact specifications before purchasing.

The specific alloy and tempering conditions of the aluminum sheet can vary depending on the desired properties and intended use of the material. For example, 1/4" aluminum sheet is available in alloys such as 6061, 5052, and 7075, each with unique characteristics in terms of strength, corrosion resistance, and machinability.

1/4 6061 Aluminum Plate

1/4 inch 6061 aluminum plate is used in industrial and architectural applications requiring high strength and good weldability for machine parts, frames and structures.

- Aerospace industry: used for aircraft components such as wings, fuselage frames, and landing gear.

- Automotive industry: for structural components such as chassis, wheels and body panels.

- Marine industry: Hulls and other components requiring high strength and corrosion resistance.

1/4 5052 Aluminum Plate

- Marine and automotive industries: Hulls, fuel tanks and other components requiring high corrosion resistance.

- Construction industry: Construction of roof and siding, gutters and other exterior components.

- Electrical industry: used in electrical enclosures, switchgear and other equipment requiring high conductivity and corrosion resistance.

1/4 inch 7075 Aluminum Plate

The aerospace industry is used for wing spars, landing gear, structural parts and other aircraft parts that require high strength and fatigue resistance

Defense industry for military aircraft and missile components requiring high strength and toughness

Industrial and sporting goods industries for applications requiring high strength and toughness, such as bicycle frames, rock climbing equipment and baseball bats

How Strong is 1 4 Inch Aluminum Plate?

The strength of 1/4" aluminum sheet depends on the specific alloy and temper of the material. In general, aluminum is a relatively lightweight and low-density material compared to other metals such as steel, but it has a good strength-to-weight ratio, making it a popular choice for many applications.

- 1/4" plate made of 6061-T6 aluminum alloy has a tensile strength of approximately 45, 000 psi (pounds per square inch)

- Plates made from 7075-T6 aluminum alloy have a tensile strength of approximately 83, 000 psi (pounds per square inch) psi.

These values may vary depending on the exact material properties, but they give an idea of the relative strength of different aluminum alloys.

It is important to note that the strength of aluminum is also affected by factors such as the geometry of the part, the manufacturing process and any surface treatments or coatings applied to the material. Also, aluminum has low fatigue strength compared to some other metals, so it may not be suitable for applications involving cyclic loading.

1/4 inch aluminum sheet is a strong and durable material in many applications, but it is important to consider the specific alloy and temper of the material and application requirements to ensure it meets the necessary strength and performance requirements.

How much does 1 4 Aluminum Plate Weigh?

The weight of a 1/4" aluminum sheet depends on its size and the specific alloy used. However, here are some approximate weights for common sizes of 1/4" aluminum plates made from different alloys:

- 1/4 inch 6061 aluminum plate weighing 1 square foot weighs approximately 2.70 pounds (or 0.012 kilograms per square centimeter).

- 1/4 inch 5052 aluminum plate weighing 1 square foot weighs approximately 2.64 pounds (or 0.0118 kilograms per square centimeter).

- 1/4 inch 7075 aluminum plate weighing 1 square foot weighs approximately 3.01 pounds (or 0.0135 kilograms per square centimeter).

Again, these are approximate weights and may vary slightly depending on the exact size and alloy used. It is best to confirm the weight of a specific piece of aluminum with the supplier or manufacturer to ensure accuracy.

What is the Best Way to Cut 1 4 Aluminum Plate?

There are many ways of cutting 1 4 aluminum plate, each has advantages and disadvantages. Here are some of the most common methods:

- Shearing: This method involves cutting the sheet with a sharp blade and can be done manually or with a mechanical shear. Shearing is a relatively quick and precise method, but it can produce rough edges that require additional finishing.

- Sawing: Using a saw with a fine-toothed blade, such as a carbide circular saw or a band saw, is an effective way to cut through aluminum panels. Sawing is slower than shearing, but it usually produces smoother edges that may not require additional finishing.

- CNC cutting: Computer Numerical Control (CNC) cutting involves the use of computer-controlled machines to cut aluminum sheet according to a specified design. This method produces very precise cuts with minimal waste, but it can be more expensive and time-consuming than other methods.

- Waterjet cutting: Waterjet cutting uses high-pressure water jets and abrasive particles to cut aluminum sheets. This method is very precise and can produce complex shapes, but it can be expensive and can result in rough edges that require additional finishing.

The best method for cutting 1/4" aluminum will depend on factors such as the application, the precision and finish required, and the equipment and resources available. It's always a good idea to consult an expert or specialty fabricator to determine the best cutting method for your needs.