4x4 Aluminum Sheet

Alloys: 6061/5052/3003/5086/2024 Complete Specifications

4x4 aluminum sheets generally refer to aluminum panels that are 4 feet (48 inches) long and 4 feet (48 inches) wide. These sheets come in various thicknesses and are commonly used in a variety of applications such as the construction, automotive, aerospace and marine industries.

4x4 Aluminum Sheets are versatile and can be easily cut, formed and formed to meet the specific requirements of different applications. They are lightweight and corrosion resistant, making them ideal for use in harsh environments.

4x4 Aluminum Sheet Specifications

Specifications for 4x4 aluminum sheets may vary by supplier and intended application. However, some common specifications for 4x4 aluminum panels include:

- Typical Thickness: 0.025 - 0.125" (0.63 - 3.18mm)

- Certifications: Some suppliers may offer certifications for specific industries or applications, such as aerospace or automotive.

- Finishes: 4x4 aluminum panels are available in a variety of finishes including burnished, brushed, anodized and painted.

- Packaging: Depending on the supplier, 4x4 aluminum panels may be available in a variety of packaging options such as crates, pallets or individual boxes.

- Available Alloys: 4x4 aluminum panels can be made from a variety of aluminum alloys including 3003, 5052 and 6061.

It is important to note that these specifications are general and may vary depending on the specific requirements of the vendor and application.

Typical 4x4 Sheet Aluminum Alloy

4x4 aluminum sheets made from various alloys are used in a wide range of applications and industries, depending on the specific properties and intended use of the alloy. Here are some examples:

- 6061-T6: For structural applications such as truck beds, trailer floors and ramps, as well as the marine and aerospace industries.

- 5052-H32: Used in the marine and transportation industries for its corrosion resistance and formability, as well as in architectural and decorative applications.

- 3003-H22: For general sheet metal processing, fuel tanks and packaging.

- 5086-H32: Used in the marine and transportation industries for its strength and corrosion resistance.

- 2024-T3: For aerospace and structural applications.

It is worth noting that the state of the alloy also affects its properties and applications. For example, the "T6" temper of 6061 aluminum refers to a solution heat treated and artificially aged condition that provides high strength and hardness, while the "H32" temper of 5052 aluminum refers to a strain hardening and stabilizing condition that provides improved formability and corrosion resistance.

High-quality 4x4 Aluminum Sheet

- Advanced Alloys: The quality of aluminum sheet is largely dependent on the grade of alloy used. High-quality 4x4 aluminum plate is made of high-grade alloy for better strength, durability and corrosion resistance.

- Accurate thickness: The thickness of the aluminum plate should be accurate and consistent throughout the sheet. This is important to ensure the board performs as intended and is suitable for the intended application.

- Smooth Surface Finish: A smooth, even surface finish is important for aesthetics as well as ensuring that the board is suitable for certain applications.

- Free from Defects: The board is free from any defects such as cracks, dents, scratches or other defects that may affect its performance or appearance.

- Certifications: The boards are accompanied by relevant certifications such as material certifications, quality certifications and test reports to ensure that they meet the required standards.

- Proper Packaging: The boards are properly packaged to prevent any damage during shipping and storage.

- GOOD CUSTOMER SERVICE: A quality 4x4 aluminum sheet supplier has a good customer service team to help customers with any questions or concerns they may have, and to assist with any issues that may arise.

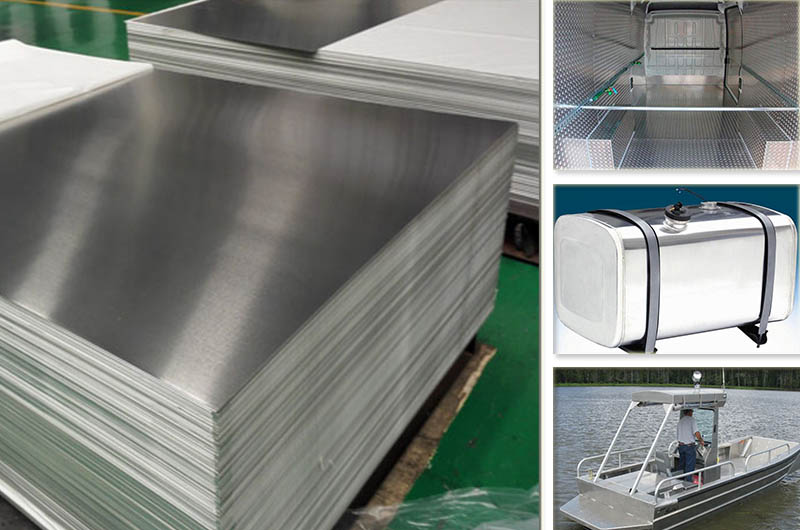

4x4 Aluminum Plate Sheets Applications

- Structural components in the aerospace, automotive and marine industries.

- Machine components in manufacturing and industrial environments.

- Architecture and construction, such as facades, roofs and interior design elements.

- Transportation equipment such as trailers, trucks and railcars.

- Electrical and electronic enclosures and assemblies.

- Food and beverage industry equipment and storage.

- Sports and recreational equipment such as snowmobiles, ATVs and boats.

- Medical and laboratory equipment and devices.

- Signage and advertising displays.

- Art and decorative installations and sculptures.

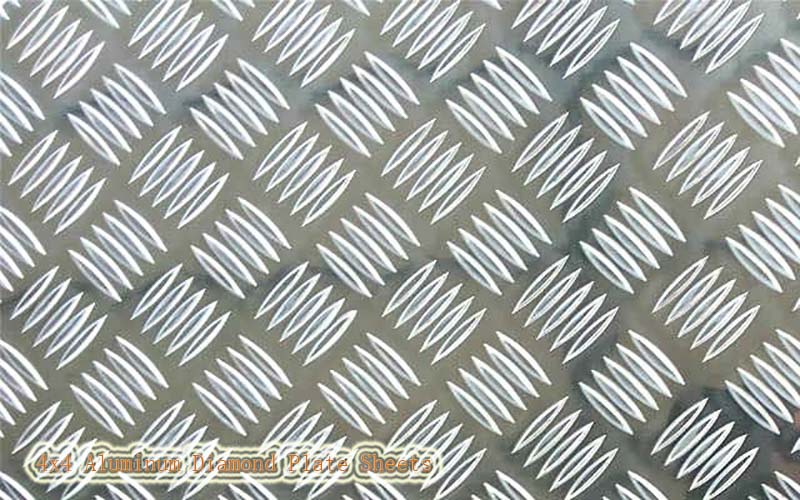

4x4 Aluminum Diamond Plate Sheets

4x4 aluminum diamond plates are usually made of high-quality aluminum alloy with a raised diamond pattern on one side to increase grip and traction. They are commonly used in applications requiring a non-slip surface such as ramps, stair treads, trailer floors and truck bed liners.

Typical thicknesses for 4x4 aluminum diamond plates can vary from 1/16" to 1/4" depending on the specific application and load requirements. These sheets may be certified to industry standards and may have a finish such as anodizing or powder coating for added durability and corrosion resistance.

When purchasing 4x4 diamond aluminum panels, customers must determine factors such as size and thickness options, certification to relevant industry standards, and the quality and durability of the product. The non-slip properties, durability, and versatility in various applications of these Diamond Plate Sheets require consultation with specific suppliers.