Perforated Aluminum Sheet

Alloy: 3003/5052/6061 Hole Shape: Round/Square/Custom

What is Perforated Aluminum Sheet?

Perforated aluminum sheet refers to an aluminum sheet that has been mechanically stamped or stamped to form a pattern of holes or perforations. These perforations can come in a variety of shapes, sizes and patterns, depending on the desired functionality and aesthetic appeal. Perforated aluminum panels offer multiple benefits including ventilation, light diffusion, sound absorption and aesthetic appeal.

Perforated Aluminum Sheet Specifications

Alloy and Temper

Commonly used alloys for punching aluminum sheets are 3003, 5052, 6061, etc. The choice of alloy depends on factors such as strength, corrosion resistance, and formability requirements.

The temper of the alloy can vary, but commonly used tempers include H14, H24, and T6. These tempers offer different levels of hardness, temper and formability.

Sizes of Perforated Sheet

Sheet thickness: Perforated aluminum sheets are available in a variety of thicknesses, typically 0.8mm to 6mm, depending on the application and required strength.

Paper Size: Standard paper sizes are usually available, such as 4x8 feet (1220x2440 mm) or 4x10 feet (1220x3050 mm). However, custom sizes can be manufactured to meet specific requirements.

Hole Size and Shape

Aperture and center distance

Hole Diameter and Center Distance: The diameter of the holes and the distance between centers can be adjusted to achieve the desired opening area and perforation density.

Pore size can vary depending on intended use and desired open area. Common hole sizes range from 1 mm to 6 mm, but larger or smaller sizes are also possible.

Hole Shape

The shape of the holes can be customized to meet specific needs. Common shapes include round, square, slotted or ornamental. Custom hole shapes can also be manufactured.

Surface Treatment

The finish of the perforated aluminum sheet can be selected according to the desired appearance, corrosion resistance and durability.

- Anodizing: Anodizing is a common surface treatment that provides a protective oxide layer, improves corrosion resistance, and provides color options.

- Powder Coating: Powder coating is another finishing option that offers a durable and decorative finish in a variety of colors.

- Paint: Perforated aluminum panels can be painted to enhance the look and provide additional protection.

It is to be noted that specific applications may have unique requirements, therefore it is advisable to consult the manufacturer or supplier for accurate information on the alloy, condition, hole size and shape, sheet size and finish of the perforated aluminum sheet used in a particular application. application.

Typical Perforated Aluminum Sheet

1/8 Perforated Aluminum Sheet

- Alloy: Typically made of 3003 aluminum alloy or similar.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Hole Diameter and Center Distance: The hole diameter and center distance may vary by specific product, but for 1/8 perforated aluminum plate, the hole diameter is usually about 1/8 inch (3.175mm), and the center distance between the hole diameter and center distance hole is also about is 1/8 in.

- Hole shape: usually a round hole.

- Finish: Finish options may include satin (uncoated) or painted.

- Specifications: Standard paper size is usually 4'x8' (4'x8'), but custom sizes are also available.

- Common uses: HVAC (heating, ventilation, and air conditioning) systems, speaker grills, filters, decorative applications, and more.

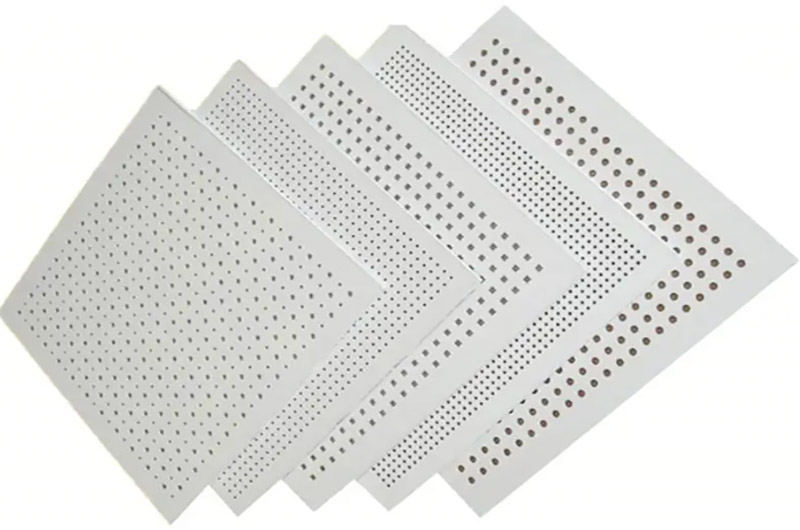

White Perforated Aluminum Sheet

- Alloy: Similar to 1/8 punching plate, it is usually made of 3003 aluminum alloy or similar alloy.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Hole Diameter and Center-to-Center: Similar to 1/8 perforated plate, hole diameter and center-to-center distance may vary, but are typically about 1/8" (3.175mm).

- Hole shape: usually a round hole.

- Finish: Usually painted with a white finish to achieve the desired color.

- Specifications: Standard paper size is usually 4'x8', but custom sizes are also available.

- Common uses: architectural applications, interior design, wall panels, ceilings, decorative elements, and more.

3/16 Perforated Aluminum Sheet

- Alloy: Usually made of 3003 aluminum alloy or similar alloy.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Hole Diameter and Center Distance: The holes in 3/16 perforated aluminum plate are approximately 3/16" (4.763mm) in diameter with corresponding center distances from hole to hole.

- Hole shape: generally a round hole.

- Finish: Finish options may include sanding or painting.

- Specifications: Standard paper size is usually 4'x8', but custom sizes are also available.

- Common uses: grilles, protective covers, sun visors, acoustic panels, filtration systems, industrial applications, etc.

Black Perforated Aluminum Sheet

- Alloy: Similar to other punching plates, it is usually made of 3003 aluminum alloy or similar alloys.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Bore diameter and center distance: Bore diameter and center distance may vary, but generally follow the specifications of the specific product.

- Hole shape: generally a round hole.

- Finish: Painted in black finish for desired color and look.

- Specifications: Standard paper size is usually 4'x8', but custom sizes are also available.

- Common uses: architectural applications, interior design, decorative panels, speaker grills, automotive components, etc.

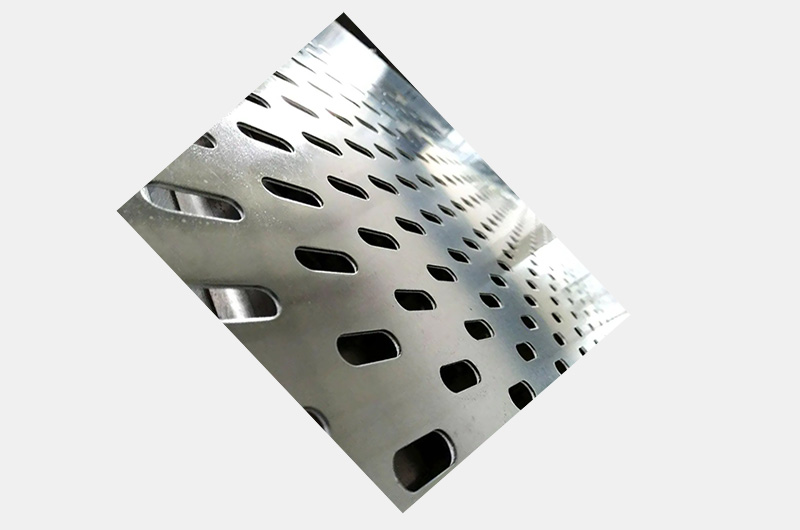

Oval Perforated Aluminum Sheet

- Alloy: Usually made of 3003 aluminum alloy or similar alloy.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Hole Diameter and Center Distance: The hole diameter and center distance of oval perforated panels may vary depending on the specific product and customization options.

- Hole shape: Oval hole.

- Finish: Finish options may include sanding or painting.

- Specifications: Standard paper size is usually 4'x8', but custom sizes are also available.

- Common uses: architectural applications, interior design, decorative panels, signage, privacy screens, and more.

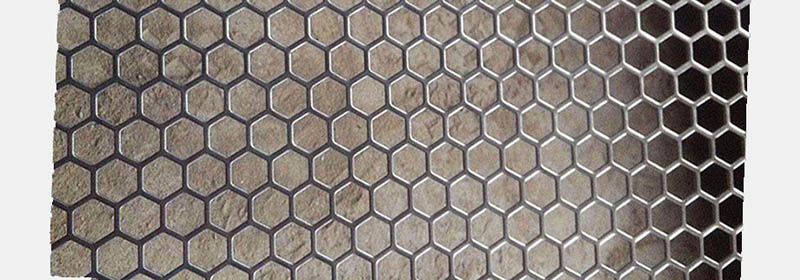

Hexagonal Perforated Aluminum Sheet

- Alloy: Usually made of 3003 aluminum alloy or similar alloy.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Hole Diameter and Center Distance: The hole diameter and center distance of the hexagonal perforated sheet may vary depending on the specific product and customization options.

- Hole shape: hexagonal hole.

- Finish: Finish options may include sanding or painting.

- Specifications: Standard paper size is usually 4'x8', but custom sizes are also available.

- Common uses: architectural applications, interior design, decorative panels, fencing, exterior walls, etc.

Perforated Aluminum Sheet 4x8

- Alloy: Usually made of 3003 aluminum alloy or similar alloy.

- Alloy Condition: Typically supplied in the annealed (O) condition.

- Bore Diameter and Center Distance: Bore diameter and center distance may vary depending on specific product and customization options.

- Hole Shape: Usually round, but custom options for different hole shapes are available.

- Finish: Finish options may include sanding or painting.

- Specifications: Specified paper size is 4'x8' (4'x8').

- Common Uses: Various industrial, architectural and decorative applications including screens, guards, partitions, filtration systems and more.

Perforated Aluminum Sheet Application

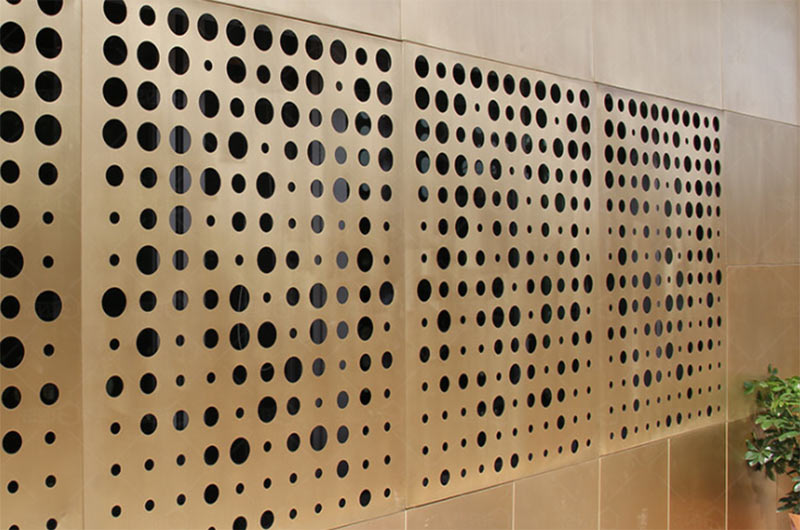

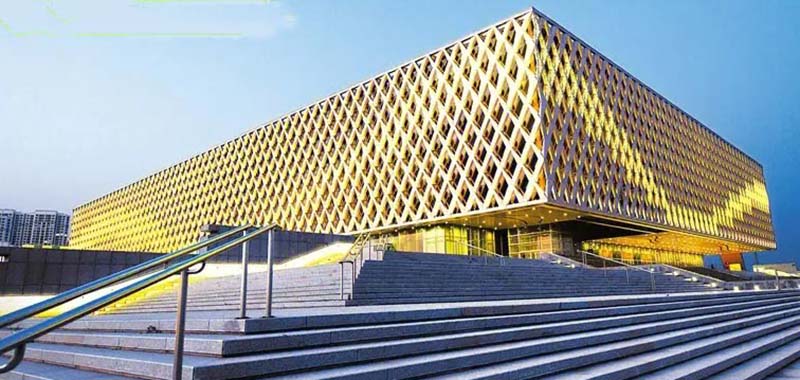

Decorative Perforated Aluminum Sheet

Perforated aluminum panels are commonly used in architectural applications such as building facades, sunshades, railings and decorative elements. They can provide functional and aesthetic advantages, allowing for airflow, light transmission, and visual interest.

- Alloys: Commonly used alloys include 3003 and 5052, which offer good strength and corrosion resistance.

- Temper: Alloy tempers can vary, but typically include H14 or H24, which provide a balance of strength and formability.

- Bore Diameter and Center Distance: Bore diameter and center distance can vary according to specific application and design requirements.

- Hole Shapes: Common hole shapes include round, square, or slotted patterns, but custom hole shapes can be manufactured.

- Finishing: Finishing options may include anodizing or powder coating to increase durability and provide a decorative finish.

- Specifications: Sheet thickness typically ranges from 1mm to 4mm, while sheet dimensions can vary depending on project needs.

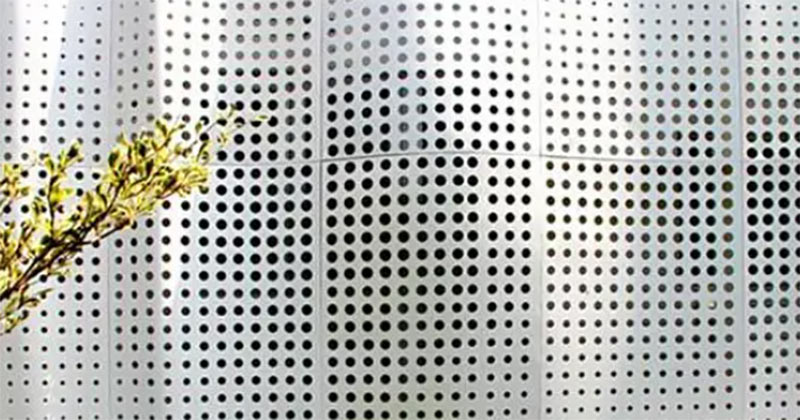

Perforated Aluminum Sheet for Building Acoustic Panels

Perforated aluminum panels can be used to build acoustic panels and sound-absorbing structures. Perforations help break up sound waves and improve acoustic performance.

- Alloys: Alloys such as 3003 or 5052 are commonly used in acoustic panels for their acoustic properties and corrosion resistance.

- Condition: The alloy condition may vary but may include H14 or H24 for best properties.

- Aperture and Center Distance: The aperture and center distance are carefully designed to achieve the desired acoustic performance.

- Hole Shape: Circular or slotted hole patterns are often used in acoustic panels to optimize sound absorption.

- Surface Treatment: Surface treatments such as anodizing or powder coating can be applied for enhanced durability and aesthetics.

- Specifications: Sheet thickness and dimensions are determined according to specific acoustic requirements and panel dimensions.

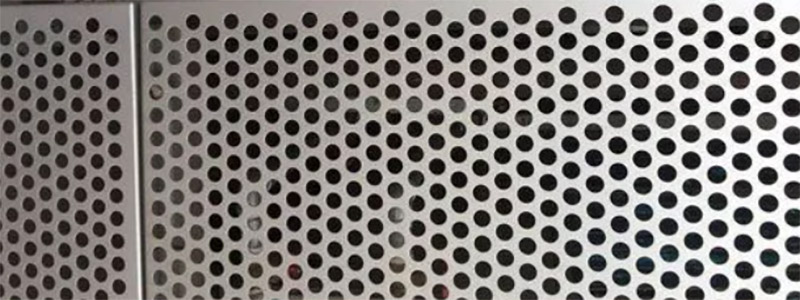

Perforated Aluminum Sheet for Filtration System

Perforated aluminum sheets are used in filtration systems, screens and sieves to separate and filter liquids, gases or solids. Pore patterns can be customized for specific filtration requirements.

- Alloys: Alloys such as 3003 or 5052 are commonly used in filtration and screening applications due to their corrosion resistance and formability.

- Condition: The alloy condition may vary, but usually includes H14 or H24 for best properties.

- Aperture and Center Distance: The aperture and center distance are customized according to specific filtration requirements.

- Pore Shape: Pore shapes can be customized according to filtration needs, including round, square or slotted patterns.

- Surface Treatment: Surface treatment may include anodizing or coating to enhance corrosion resistance and service life.

- Specifications: Sheet thickness varies according to required strength and filtration or screening application.

Industry and Manufacturing

Perforated Aluminum Sheet finds application in industrial equipment, machinery and manufacturing processes. They can be used as protective covers, ventilation panels or safety guards.

- Alloys: Alloys such as 5052 or 6061 are commonly used in industrial applications for their strength and durability.

- Temper: Alloy tempers can vary, but usually include T6 or H14 for strength and formability.

- Aperture and center distance: Aperture and center distance are customized according to specific application requirements, such as ventilation or security needs.

- Hole Shape: Circular or slotted hole patterns are often used in ventilation panels or safety guards.

- Finishes: Finishes may include anodizing, powder coating or painting for added protection and aesthetics.

- Specifications: Sheet thickness and dimensions are determined according to specific industrial equipment or machinery requirements.

It is important to note that specific alloys, tempers, hole sizes and finishes may vary depending on specific application and project requirements. Consulting the manufacturer or supplier will provide more accurate information and recommendations for perforated aluminum sheet used in these applications.